Sugar and salt are classed as hygroscopic crystalline goods. Hygroscopic crystalline goods differ from the preceding hygroscopic goods in that they have a substantially lower water content

(WC > 0 - < 1.5%), and thus belong to water content class 1 (WCC 1). Moreover, due to their crystalline structure, their adsorption behavior is governed by different rules, which means different container transport methods are used.

Crystalline goods belong to the class of goods in which respiration processes are suspended, but in which biochemical, microbial and other decomposition processes still proceed; they exhibit 3rd order biotic activity (BA 3).

Crystalline goods have particular storage climate conditions with regard to temperature, humidity/moisture and ventilation (SC VI) in order to counter the risk of deliquescence or agglomeration (sticking together).

Crystalline goods are transported in bulk containers and standard containers.

Sugar (sucrose) occurs commonly in the plant kingdom. However, only sugar cane and sugar beet are cultivated for the large-scale industrial production of sugar. Chemically speaking, both cane and beet sugar are sucrose, C12H22O11. While sugar cane is cultivated in the tropics and subtropics, sugar beet is cultivated in temperate latitudes. Given the different regions in which it is produced, sugar is transported:

- from the tropics to temperate latitudes for cane sugar

- from temperate latitudes to the tropics for beet sugar

Sugar is classified, among other things, by its purity, which determines different transport properties.

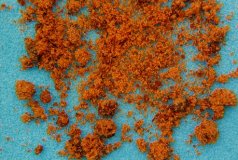

Raw sugar is a "moist", coarsely crystalline mass with a sucrose content of 95-97%. The solid cores of the raw sugar crystals are still covered with a layer of syrup. These accompanying substances make raw sugar moist and tacky and give it its typical yellow-brownish color and malty, burnt flavor. The water content of raw sugar is 0.5 - 1% (see Fig. 154).

|

Figure 154: Sucanat (whole cane sugar); Photo: U. Scharnow |

White sugar is regular consumer sugar. It is obtained from raw sugar by washing and centrifuging (affination). Its sucrose content is 99.9%.

Refined sugar is chemically ultrapure sucrose which has been obtained from white sugar by dissolution and recrystallization. It also has a sucrose content of 99.9%.

Powdered sugar is produced by grinding white or refined sugar crystals to a fine powder and sieving the powder. The max. grain size is 0.05 mm.

Salt (cooking salt), chemically sodium chloride (NaCl): mainly mined as rock salt or obtained from sea salt pans (see Fig. 155). Depending on how it is produced, salt is classified as rock salt or boiled salt. Rock salt, which is mined and finely ground, is primarily used in the food industry. Boiled salt is obtained from brine and has a higher content of magnesium chloride and calcium chloride than rock salt, as a result of which it is more highly hygroscopic than rock salt, with the finely divided grades being more highly hygroscopic than the coarser grades. Boiled salt also agglomerates more readily than rock salt.

Figure 155: Refined rock salt; Photo: U. Scharnow |

|

Hygroscopicity

Initially, crystalline goods hardly respond at all to the water vapor content of the ambient air, such that their water content is close to 0% (flat adsorption isotherm). Only once the flow moisture point is reached, which for example for sugar is > 80%, does the sugar absorb water vapor so quickly and in such large quantities that it deliquesces (abrupt rise in adsorption isotherm) and loses its flowability (see Fig. 156). When moistened sugar dries out, it releases the absorbed water vapor to its surroundings and hardens and cakes.

|

Figure 156: Sorption isotherms for white sugar — 20°C --- 10°C |

The sorption isotherm for cooking salt (see Fig. 157) shows that it absorbs virtually no water vapor from its surroundings at relative humidities of up to 74%. Once the water content has risen from 0.05% to 0.5%, so reaching the flow moisture point, salt begins to absorb water vapor so readily that it passes into solution at a relative humidity of 75%.

|

Figure 157: Sorption isotherm for cooking salt (sodium chloride, 20°C) |

Behavior of sugar in a container in the event of temperature changes

- Transport of raw sugar from the tropics to temperate latitudes (see Fig. 158).

This applies, for example, to the transport of sugar from Central America to Europe. Especially during winter in the northern hemisphere, cargoes of sugar on this route are at risk due to the temperature differences. Air and water temperatures begin to drop from around 20°N and continue to do so until arrival in Europe. Over this voyage of approx. 4000 sm, air temperature may be expected to fall, for example, from 28°C to 2°C, with water temperature dropping from approx. 20°C to 5°C. A drop in air temperature of around 26°C and in water temperature of around 23°C create the conditions for caking of the sugar in the container. Investigations have shown that losses due to caking are at their highest in the cold season. However, losses due to caking are particularly prevalent when relative humidity falls below 50%.

Figure 158:

Travel from hot to cold regions: The cargo block cools down from the outside, resulting in water vapor transport from the warm core to the outside; caking in the interior due to water vapor release from the hot cargo [27]Figure 159:

Travel from cold to hot regions: the cargo block is heated from the outside, resulting in water vapor transport from the outside to the cold core; caking on the outside, wetness on the inside [27]

- Transport of white sugar from temperate latitudes to the tropics (see Fig. 159).

On relatively long voyages, the inner bags of the stack remain cold for longer; due to the different sorption behavior, water vapor is conveyed from the warmer outer sugar to the colder sugar inside the stack. This results in water stains on the sugar bags and, on the basis of the above observations, syrup formation may be expected. Subsequently, once the internal sacks have also warmed up, severe caking starts to occur. Crystalline goods are now predominantly transported in double-layered packaging consisting of a outer, woven bag and an inner, plastic film bag. This avoids the risk of water vapor adsorption or caking when the white sugar redries (see Figs. 160, 161).

Figure 160: Double-layered bags containing white sugar: outside, natural fiber fabric; inside, plastic;

Photo: U. Scharnow

Figure 161: Palletized double-layered plastic bags containing white sugar;

Photo: U. Scharnow

Since crystalline goods are virtually exclusively transported in combined fabric/film bags, they are not very sensitive to (dust) contamination. Deposits on the bags may result in losses. Containers must be sufficiently clean for food cargoes. Crystalline goods, such as sugar and salt, are basically clean foodstuffs which are packaged hermetically. If packaging is damaged during loading, salt in particular may have a strong corrosion-promoting effect on other goods.

Fire hazard

Smoking must be strictly prohibited during container packing and unpacking. Discarded cigarette ends can cause sugar fires. Cigarette ash acts as a catalyst in sugar combustion. Sugar fires are greatly feared because they are difficult to extinguish, requiring the use of carbon dioxide or other chemical extinguishing agents.