The term "semiluxury items" covers foodstuffs generally of vegetable origin, which have a stimulating, pleasant effect. They include for example coffee, cocoa, cola, coca, betel, tobacco and tea. Here, we shall look particularly at coffee and cocoa on the one hand and tobacco and tea on the other.

With low water contents, which amount to 4 - 14%, e.g. coffee 9 - 13%, cocoa 5 - 6%, tea 4 - 6% and oriental tobacco 12 - 14%, these goods are among those whose respiration processes are suspended but in which biochemical, microbial and other decomposition processes still proceed, i.e. goods displaying 3rd order biotic activity (BA 3) (see Table. 20).

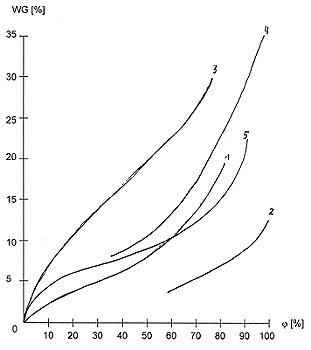

Coffee, cocoa, tea and tobacco require particular temperature, humidity/moisture and possibly ventilation conditions (SC VI). Their sorption isotherms (see Fig. 130) exhibit a continuous S-shaped profile. If they become damp, they may go moldy and undergo self-heating. On the other hand, they are subject to drying-out, associated with loss of aroma, if humidity levels are too low. Moisture and heat tend to cause postfermentation. They do not have any particular requirements as to ventilation conditions, if they are container dry.

|

Figure 130: Sorption isotherms for semiluxury items

|

Due to their stringent requirements with regard to temperature and relative humidity, semiluxury items should be transported in ventilated containers (coffee containers). In addition to coffee, it has also proved possible to transport tea and oriental tobacco, in particular, in standard containers.

Below are Figures illustrating coffee (131 - 135), cocoa (136 - 138), tobacco (139 - 144, 147-148) and tea (145, 146, 149-153).

Transport instructions and damage

General

Green coffee beans and raw cocoa (cocoa beans) are seeds which have had the husk removed by fermentation and, in the case of coffee, also the silver skin. In the case of coffee, these seeds are still viable. Tea and tobacco consist of fermented, dried leaves. Unlike green coffee beans, raw cocoa and leaf tobacco, tea is exported in ready-to-use form (green and black tea). As semiluxury items (stimulants), coffee contains the alkaloid caffeine (0.8 - 2.5%), cocoa contains theobromine (1 - 2%) and caffeine (0.2%), tobacco contains nicotine (0.5 - 3%) and tea theine (2.5 - 5%). Due to its high content of fat (cocoa butter), protein and carbohydrates, cocoa also has a high nutritional value.

Processing methods

Coffee, cocoa, tobacco and tea are processed using fermentation. In the case of coffee, a distinction is drawn between dry processing and wet processing, Wet-processed coffee tends to go moldy and to suffer self-heating more quickly than dry-processed coffee. The ability to germinate is also retained despite fermentation. The loss of the ability to germinate has an unfavorable effect on the constituents and thus also on the quality of the green coffee beans (see Figs. 131-135).

|

Figure 131: Coffee

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

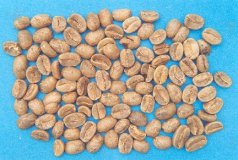

| Figure 132: Green coffee beans, Peruvian arabica; Photo: U. Scharnow |

Figure 133: Green coffee beans, Ugandan natural robusta; Photo: U. Scharnow |

|

|

| Figure 134: Wet-damaged green coffee beans, stuck to the sacking; Photo: Goy |

Figure 135: Swollen green coffee beans;

Photo: Goy |

Although cocoa beans lose their ability to germinate as a result of fermentation, poorly fermented cocoa beans may germinate. Over- and underfermentation may impair quality (see Figs. 136 - 138).

|

|

| Figure 136: Cucumber-like cacao fruit on the trunk of the cacao tree (cauliflory); Photo: U. Scharnow |

Figure 137: Cocoa beans (raw cocoa); Photo: U. Scharnow |

|

Figure 138: Container with wetting damage raw cocoa, sides lined with paper dunnage; Photo: Stradt |

In the case of tobacco, a distinction is drawn between natural curing (sun curing of Oriental tobaccos, see Figs. 139 and 140, highly weather-dependent) and artificial curing (generally used for Virginia tobacco, see Fig 141). Two types of fermentation are used, natural and chamber fermentation.

|

|

| Figure 139: Curing of tobacco leaves in Bulgaria; Photo: U. Scharnow |

Figure 140: Curing of tobacco leaves in Bulgaria; Photo: U. Scharnow |

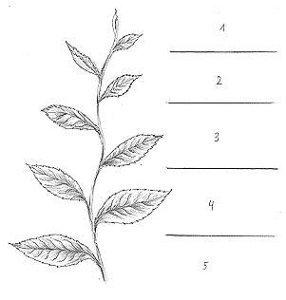

The tobacco leaves, which are harvested at different times, are known as (from bottom to top = stalk position) primings/flyings, lugs, cutters, leaf, tips (see Fig. 141).

|

Figure 141: Tobacco plant: names for foliage [50] |

Familiar types of tobacco are Oriental (see Fig. 142) and Virginia (see Fig. 143). Cigarette tobacco, e.g. American Blend, which is a mixture of Virginia, Burley and Oriental, is transported all over the world.

|

|

| Figure 142: Oriental tobacco from Greece, sun-cured; Photo: U. Schieder |

Figure 143: Virginia tobacco from the USA; Photo: U. Schieder |

|

|

| Figure 144: Burley tobacco (ribs); Photo: U. Schieder |

Figure 145: Tea branch |

Tea is divided into leafy and broken grades; the youngest, small top leaves (pekoe tips) provide the most valuable teas (see Fig. 146).

|

Figure 146: Tea grades as a function of leaf size -

|

Tea is withered, rolled, fermented and dried.

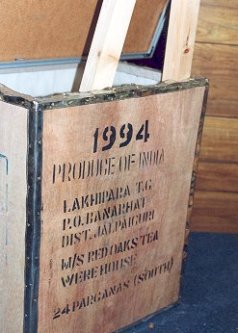

Packaging

Coffee and cocoa are transported in new, air-permeable, natural fiber bags (sisal, jute). If plastic inner bags are used, they must be perforated. Tobacco is exported in bales, which are wrapped in natural fiber fabric (see Fig. 147) (jute, linen or blended fabric). Oriental tobacco is transported in cartons (see Fig. 148) in standard containers, having been separated into leaves and ribs (see Fig. 144). Since carton dimensions are adapted to container dimensions, full container loads (FCL) can easily be achieved in standard containers.

|

|

| Figure 147: Tobacco in bales (natural fiber fabric) from Turkey; Photo: U. Schieder |

Figure 148: Tobacco in cartons, strapped with steel straps; Photo: U. Schieder |

Tea is packaged in plywood chests which are lined with aluminum foil and parchment paper, the corners being covered with sheet metal (see Figs. 150, 153). 10 - 25 packages are combined to form a palletized unit.

|

| Figure 149: Tea gardens in Grusinia; Photo: Ragna Scharnow |

|

|

| Figure 150: Tea chests from Japan; Photo: U. Scharnow |

Figure 151: Flowery pekoe leaf grade: finest Ceylon harvest F.P. Photo: U. Scharnow |

|

Figure 152 (top): Green tea from China; Photo: U. Scharnow |

| Figure 153 (left): Plywood tea chest with aluminum foil and parchment paper, the corners being covered with sheet metal |

Hygroscopicity

The semiluxury items coffee, cocoa, tobacco and tea are strongly hygroscopic. The values stated in the Table below are respectively averages and ideal temperatures.

| Semiluxury item | Water content in % |

Equilibrium moisture content in % |

Temperature in °C |

| Coffee | 10 (crit. 12) | 50 - 65 | 5 - 25 |

| Cocoa | 6 - 8 (crit. 8.5) | 70 | 15 - 25 |

| Oriental tobacco | 12 - 14 | 60 - 65 | 5 - 25 |

| Virginia tobacco | 10 - 13 | 50 - 65 | 5 - 25 |

| Tea | 4 - 6 | 50 - 60 | 5 - 25 |

Table 23: Water contents, equilibrium moisture content and temperature of semiluxury items

[28]

The stated temperature ranges are those at which the individual semiluxury items can be stored for the longest period without quality degradation (optimum storage or transport temperature). Upward or downward deviations reduce the storage period within which no quality degradation is to be expected. The greater the deviation from the optimum storage or transport temperature, the greater the risk of quality degradation.

Their sorption isotherms (see Fig. 130) exhibit an S-shaped profile. Cocoa beans are the semiluxury item which displays the greatest moisture sensitivity. At the time of container packing, the water content is 6 - 8%, which corresponds to an equilibrium moisture content of 75 - 85% and a temperature/dew point difference of 5 - 3°C. These are values which entail greater problems than are encountered, for example, with coffee transport, because even the lower water content limit of 6% corresponds to the mold growth threshold. Moreover, cocoa beans have an elevated fat content of 39 - 60% which, in conjunction with moisture, results in hydrolytic/enzymatic fat cleavage and thus in self-heating of the cocoa beans. The small temperature/dew point difference also shows how rapidly the dew point of the cocoa cargo is reached on cooling. A water content of 6% is thus recommended when transporting cocoa beans in containers.

Semiluxury items should be processed and dried/cured after harvesting to such an extent that they reach fitness for container transport. After processing, they must be stored in dry conditions or preferably loaded as soon as possible. Over an extended storage period in a damp, tropical climate (e.g. during the rainy season), water vapor is absorbed, which may lead to moisture damage. This may take the form of mustiness, mold, swelling or self-heating. Moreover, postfermentation may be activated (see Figs. 134, 135). In the case of tea, excessively high water contents lead to mold and mustiness. On the other hand, if the water content of tea and tobacco falls below the admissible value, they will dry out, suffer fragmentation damage, loss of aroma and leaf breakage and turn to dust. Oriental tobaccos are the most sensitive to moisture of all tobaccos. Mold (Oespora tabaci) may appear within three days, together with mustiness and decay, and may be recognized from white, grey, green and black spots on the tobacco bales.

Temperature

The temperatures stated in Table 23 are the temperatures favorable for semiluxury items. If the temperatures stated in Table 23 are exceeded markedly, with coffee the risk of rancidity and overfermentation increases. In extreme cases, the embryo may even die and rot (stinker).

With cocoa, temperatures > 30°C increasingly promote postfermentation, rancidity and self-heating. On the other hand, it must be protected from frost.

Ventilation

- Standard containers

The ventilation holes in standard containers have no ventilation effect

During a voyage from the tropics to temperate latitudes, a sudden drop in temperature has to be expected especially in the winter months. The temperature gradient may amount to as much as 50 - 60°C, especially during winter in the northern hemisphere.

Due to the associated severe cooling, the temperature may reach or even fall below the dew point, resulting primarily in condensation (sweat) on the container ceiling. Dripping condensation water may cause considerable damage.

To protect the cargo, top or lateral dunnage in the form of paper or nonwoven fabric may be laid on the cargo surface and between the cargo and the container walls. Since paper is markedly less absorbent than nonwoven fabric, nonwoven fabric is preferred for the cargo surface (see Fig. 138). Both options are only temporary measures, since their absorbency is limited. It is therefore advisable to stow the containers below deck, in order to avoid container sweat caused by the steep temperature gradient on deck. If bulk loading (coffee) is used, a liner bag with integral nonwoven fabric suspended in the standard container offers the possibility of minimizing damage.

- Ventilated containers

Since hygroscopic semiluxury items constantly release water vapor during the voyage, with this reaching markedly more than 100 liters in a 20' container in extreme cases, this vapor must be removed by ventilation in order to reduce the risk of condensation in the event of unfavorable ambient conditions (sudden drops in temperature of the external air) in the container. Relatively high humidities bring with them the risk of mold growth and self-heating. To optimize ventilation in a passively ventilated container, the container must be stowed below deck (under the hatch). As soon as the external temperature falls below loading temperature and the relative humidity is no longer above the loading humidity, it is advisable to assist passive ventilation. The "chimney" effect must be achieved by vigorous ventilation of the hold, with the air being blown in from beneath and rising upwards through the container cargo, so continuously removing warm, moist air.

Dunnage is only laid on the floor; at the sides and in the top area the ventilation effect would be impaired. It is also important to unpack (strip) the containers quickly on arrival at the port of destination. Especially at cold times of year, when the containers are removed from the relatively protected environment of the ship's hold, the core temperature of coffee may still be 18 - 20°C. If they are then exposed to the sometimes substantially lower external temperature, the humidity in the containers rises rapidly, so causing condensation to form.

Ventilated containers are used to transport tobacco from regions with critical climatic conditions (e.g. Indonesia, Dominican Republic).

All semiluxury items are capable of absorbing foreign odors, if the containers are not clean and odor-free prior to packing. Any residues from previous cargoes, especially odor- and flavor-tainting cargoes, must be removed. It may be necessary to wash the container. If the previous cargo was extremely strong-smelling, e.g. salted hides, the container must be rejected. Unsealed container floors cannot be lastingly cleaned of these odors - only replacement of the container floor is sufficient.

Contamination

All semiluxury items are extremely sensitive to contamination and care should therefore be taken, when packing and unpacking a container, to ensure that contamination from ground conveyors, e.g. hydraulic oil, grease etc., is not transferred to the sensitive cargo. Dunnage, where used, must also be dry, odor-free and clean.

After washing, care must be taken to ensure that the container floor has dried out. The moisture content of the container floor should amount to no more than 12% at an equilibrium moisture content of 70%.

Mechanical influences

Before ground conveyors with squeeze clamps are used to pack and unpack the containers, checks must be carried out to find out what clamping pressure the packaging (cases, bales or cartons) is designed to withstand. If coffee or cocoa is to be loaded in bags, only bag hooks must be used; under no circumstances should a longshoreman's hook be used.

Toxicity/Hazards to health

Postfermentation causes CO2 production. In unfavorable cases, high carbon dioxide contents may arise. Contents of 8 - 10 vol.% are lethal within just five to ten minutes! Since CO2 is heavier than air, it "flows" out like water when the container is opened. It is therefore highly unlikely that a situation which was hazardous to health would arise in the container. If a container has been fumigated to combat pests, the container must be marked accordingly. Prior to packing, the container must be ventilated in accordance with the instructions relating to the pesticide.

Insect infestation

Some pests specialize in infesting the corresponding cargo type, e.g. the coffee beetle, the cacao moth and the tobacco beetle (cigarette beetle). The tobacco beetle is in particular brought on board in the tropics and subtropics. The cocoons are attached to the interior of the packages. The larvae chew round holes in the tobacco leaves. For the purpose of identifying any pests, traps are set in the container which are checked on unpacking. Infested cargoes must be fumigated, but their quality may well be degraded as a result. A fumigation certificate must be presented in this case.