Introductory remarks

There are undoubtedly many companies in which responsible, quality-conscious staff plan and devise optimum transit procedures so that the goods to be shipped reach the receiver having suffered the least possible damage. In such companies, prevention of damage is a priority since it is common knowledge that economic success is to a great extent dependent upon customer satisfaction. Considerable effort is taken to avoid shipping damage or to restrict the extent of such damage.

But what about those personnel who don't care as much about preventing damage? Virtually inevitably, their actions or omissions cause damage and accidents.

|

||

| Human failure as a cause of damage | ||

It's not the ship's management or crew who have fallen short here, but those who were responsible for packing some of the containers. Nothing has happened to properly packed and secured containers, while poorly packed containers with inadequately secured cargoes have been destroyed.

This Container Handbook only occasionally takes a look at spectacular incidents of damage and instead primarily focuses on the numerous small and medium-sized cases of carelessness in shipping which are responsible for the majority of losses as they rapidly add up to huge sums of money.

|

||

| Human failure - from another perspective | ||

Only poorly packed containers with inadequately secured cargoes have been destroyed. Even the vehicles labeled 1 and 2, which were not ideally secured, have withstood the effects of the rough seas.

Analysis of shipping losses frequently focuses on technical issues and takes human shortcomings more or less as read. Such an approach is mistaken, ultimately meaning that the necessary staff training is not provided because it is not regarded as sufficiently important, an attitude shared by the decision-makers.

|

Damaged containers should not be used. |

Insufficient knowledge and inadequate skills on the part of many of those involved in cargo shipping are the root causes of subsequent losses. Errors in the planning and execution of transport operations are for the most part due to human failure.

|

|

| Inadequate training promotes damage. |

Poor understanding on the part of many of those in charge about the complex interrelationships involved in the provision of transportation services together with what is in most cases a very low level of training among the personnel involved with the physical handling of cargoes conspire to cost the world's economy billions every year.

| Insufficient knowledge and inadequate skills on the part of very many of those involved in cargo shipping are the root causes of subsequent losses. |

Basic errors are sometimes made as early as during design and production of the goods which are ultimately to be shipped. While this area will be addressed separately in the section "Packaging errors and deficiencies", some explanatory examples are given below.

|

Non-regulation dangerous cargo unit |

Even trained packers would have difficulty packing this cargo unit safely into a container, in fact it would be impossible without additional labor and materials costs.

|

Non-regulation dangerous cargo unit |

Given the differing heights of the drums, this cargo unit is even more difficult to pack into a container.

|

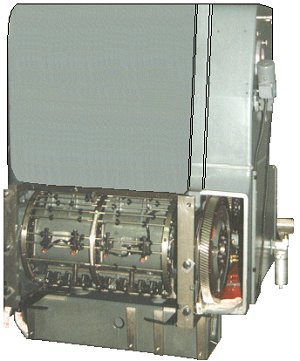

Machine without securing means: not fit for shipping |

Designers not only have to take account of a machine's subsequent function, but also of the fact that it must first be transported to where it will be used and installed there without suffering damage. Every machine should have slinging and lashing points so that it can be handled and secured without problem.

|

|

| Earth borer without securing means: not fit for shipping |

This earth borer has no lashing points. In such cases, securing means are generally attached arbitrarily to components which are not suitable for this purpose. The absence of lashing points is particularly disadvantageous since this machine will be used at many different sites. Every time the machine is moved, more effort will be required for securing, so increasing the shipping risk, which is why:

| Attention must be paid to lashing points for easy transport securing from the design stage. |