- Road transport operations may generate short-term longitudinal forces upon the cargo and the CTU. They may also cause vibrations that may vary considerably due to different suspension systems, different road surface conditions and different driving habits.

In a nutshell: anticipated stresses are determined by structural parameters of the goods and of the vehicle/vehicle combination, the position of the goods on the loading area, how fully laden the vehicle is, the condition of the roadway, the driver's habits etc. Special transport operations entail obtaining comprehensive information about the circumstances to be taken into account. Stowing and securing measures may then be tailored to the particular transport situation. If precise data are unobtainable, the values stated in the CTU packing guidelines, or the assumed loads specified by the relevant national organizations, should be taken into account.

| Mode of transport: road | Forward acting forces | Backward acting forces | Sideways acting forces |

| VDI guidelines | 0.8 g | 0.5 g | 0.5 g |

| CTU packing guidelines | 1.0 g | 0.5 g | 0.5 g |

| Swiss road transport regulations | 1.0 g | 0.5 g | 0.5 g |

| British regulations | 1.2 g | 0.5 g | 0.8 g |

In relation to the Table (see also comment on page 89), it is stated in point 1.7 of the CTU packing guidelines that examples of accelerations are given which could arise during transport operations:

-

... However, national legislation or recommendations may require the use of other values.

|

|

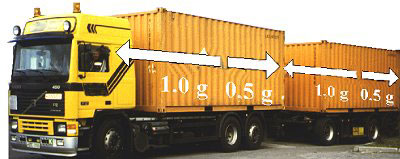

| Acceleration in longitudinal direction according to VDI guidelines |

|

|

| Acceleration in longitudinal direction according to CTU packing guidelines |

The forward acceleration of 0.8 g according to the VDI guidelines or of 1.0 g according to the CTU packing guidelines means that forces of 80% or 100% respectively of the package weight will act on the packages in this direction. Both sets of guidelines assume backward acceleration of 0.5 g, i.e. forces of 50% of the package weight will act on the packages in this direction.

|

|

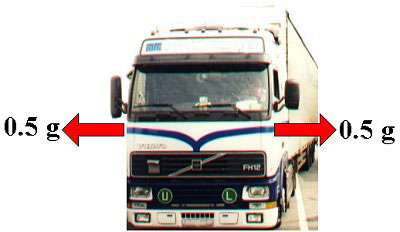

| Acceleration in the sideways direction according to the CTU packing guidelines and VDI guidelines |

Again, both sets of guidelines assume identical sideways acceleration values of 0.5 g. Forces amounting to 50% of the package weight will accordingly also apply sideways.

|

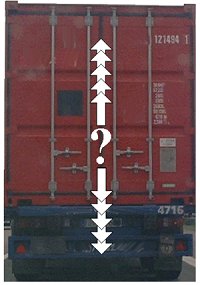

What value should be assumed for vertical acceleration? |

The guidelines make no mention of vertical acceleration. Most road users will know from their own observation that loads can even lift off during road transport, i.e. values of just above 1 g vertically are quite readily achieved.

A brochure published by the former German federal railroad company, Deutsche Bundesbahn, states:

-

Considerable stresses .... in the vertical direction also occur during road delivery operations. (...) Forces of up to 0.85 times the weight-force of the load must be anticipated in the vertical direction. Measurements, filtered at 32 Hz, carried out by the Institute for automotive transport, Hanover University of Technology.

|

|

|

| Consequences of "home-grown" acceleration forces | ||

As for every means of transport, the values stated in the guidelines only apply to loads which have been secured so that they cannot shift. If load items are able to move, considerably higher acceleration forces may come into play.

|

|

| Consequences of "home-grown" acceleration forces in a container carried by road |

An example: 8000 kg of goods in cartons had been loaded into the container in the photograph. The articulated truck carrying the container had to brake rather harder than usual at traffic lights. Although the braking deceleration was distinctly less than 0.8 g, this maximum value will be used for the purposes of the calculation. The coefficient of sliding friction of the cartons on the container floor and between the individual cartons will be assumed to be μ = 0.3. The cartons would then have been able to exert a force of only 8000 kg x 0.5 g = 3924 daN against the front end wall of the container. As will be described in greater detail elsewhere, the loading capacity of the container end wall must amount to 0.6 times the payload. In the container shown, this would amount to 10,595 daN. The forces which actually occurred were accordingly at least 2.7 times higher. A very clear case of home-grown acceleration as a result of gaps in container packing.

|

Consequences of "home-grown" acceleration forces on a small truck |

An example: A 1000 kg package had been loaded into the vehicle shown in the photograph. The vehicle was going around a curve with a radius of 25 m at a moderate speed of 36 km/h.

This generated a sideways acceleration of 4 m/s². A force of 392.4 daN was accordingly applied to the load. Assuming a coefficient of sliding friction of μ = 0.3, this force was counteracted by passive friction forces of 294.3 daN. The difference of 98.1 daN would never have been enough to smash through the sideboards and cause such damage to the vehicle. However, because the package was lying unsecured in the middle of the loading area, it was able to get a "run-up" and develop its destructive force.

The provisions governing the loading of road vehicles and the relevant accident prevention regulations specifically state that the load must be packed and secured in such a manner that, under normal traffic conditions, nothing can fall over, drop or roll off the vehicle and that any risk to life must be excluded. Usual traffic conditions in road transport include evasive maneuvers, hard braking and unevenness of the roadway which may occur simultaneously not merely separately. It should accordingly be assumed, as the basis for proper load securing, that a vehicle on a poor section of road suddenly has to brake hard and additionally execute an evasive maneuver. If the load can pass through such a situation unscathed, it may be deemed secure.

It should be borne in mind that the acceleration values which must be assumed for road vehicles according to VDI guidelines and the BGF, the German road vehicle maintenance employers' liability insurance association, correspond to the following tilts in degrees.

|

|

|

| 0.8 g forward acceleration in road transport corresponds to a tilt of 53°. | 0.5 g backward acceleration in road transport corresponds to a tilt of 30°. |

|

0.5 g sideways acceleration in road transport corresponds to a tilt of 30°. |

The loading capacity of cargo transport units is specified in standards and the International Convention for Safe Containers. The relevant sections provide comprehensive information in this respect. However, the values will also be stated here by way of comparison with shipping stresses.

| The loading capacity of the side walls of standard containers and of swap-bodies with a CSC plate corresponds to a tilt of 23.6°. |

|

With a uniformly applied load, the front end walls of standard swap-bodies and containers must be able to withstand forces of 0.4 times the payload. This corresponds to an angle of 23.58°.

|

The loading capacity of the side walls of standard swap-bodies corresponds to a tilt of 17.5°. |

With a uniformly applied load, the side walls of standard swap-bodies must be able to withstand forces of 0.3 times the payload. This corresponds to an angle of 17.46°.

| The loading capacity of the side walls of standard containers and of swap-bodies with a CSC plate corresponds to a tilt of 36.9°. |

|

With a uniformly applied load, the side walls of standard containers or of swap-bodies with a CSC plate which are used in maritime transport must be able to withstand forces of 0.6 times the payload. This corresponds to an angle of 36.87°.