Figure 3 illustrates the principle used in refrigerating porthole containers. In cooling systems permanently installed on the ship, heat is dissipated from the porthole containers via fixed ducts in the cooling system. The vertical cooling ducts are divided into two channels (supply air duct and return air duct). The supply air duct is connected to the lower aperture in the end wall of the container via switchable couplings. The cold air flows through this duct into the container below the grating, through the cargo and then back over the cargo through the upper opening via the coupling to the return air duct. The heated air is drawn off from the return air channel by the refrigeration duct fan and then conveyed back into the supply air channel by the fan.

|

| Figure 3: Schematic representation of a porthole cargo refrigeration plant comprising the cooling system, the brine system and cold air system |

Figure 3 shows an indirect system with an intermediate brine circuit which connects the cooling system which is located centrally in the engine room to the cold air system in the hold. The supply air temperature is here controlled by adjusting the three-way valve in the brine circuit. Since the installed refrigeration units are relatively large, porthole containers may thus achieve a higher level of efficiency than integral containers. The average power consumption for cooling a TEU, including all auxiliary units, is between approximately 1.5 kW (direct refrigeration plant) and approximately 2.5 kW (indirect refrigeration plant). By comparison: An integral refrigerated container requires on average approximately 3.6 kW per TEU, and between 4.2 kW and 5 kW for transport below deck with additional air cooling (see also Section 8.1.2). Average power consumption, however, depends primarily on the cargo mix and thus on the transport route.

|

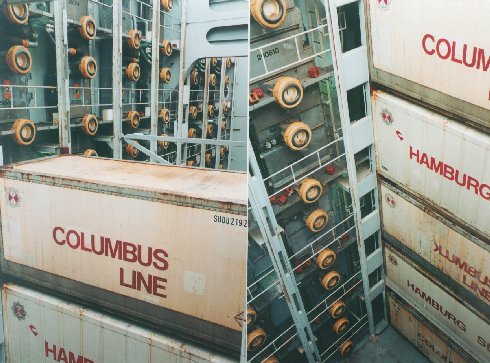

| Figure 4: Permanently installed refrigeration system supplying cold air to porthole containers on board MS Allianca Brasil |

Figure 4 shows the arrangement of the refrigeration ducts with the couplings in the hold of a container ship on which up to seven refrigerated containers can be stacked and connected to a single refrigeration duct.

Sometimes, porthole containers are also transported on deck. If this is done, a "clip-on unit" is attached to the container which supplies it with cold air. Clip-on units are also used to refrigerate the containers at terminals or when transporting them by truck (see Figure 5). They require a 3-phase power supply to operate.

|

| Figure 5: Clip-on for transport by truck; photo: K.-H. Hochhaus |