Example 1

|

|

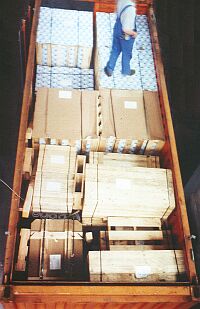

| Unsecured general cargo in a 20' open-top container |

If this container is carried by sea in this state, damage is inevitable.

Example 2

|

|

|

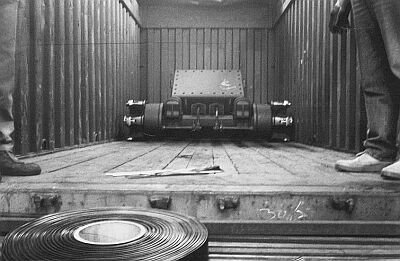

| Packing a 20' hard-top open-top container | ||

A positive feature is that a secure cargo end face towards the doors is being constructed. Setting down the larger packages in the door area saves considerable labor. In the front part, the dimensions of the packages are such that some gaps are produced. These were filled in with smaller items of cargo, wooden members, old pallets etc. in such a manner that, overall, a compact stow was achieved. There is no risk of damage to individual items of cargo.

|

Final work on a 20' hard-top open-top container |

Example 3

|

|

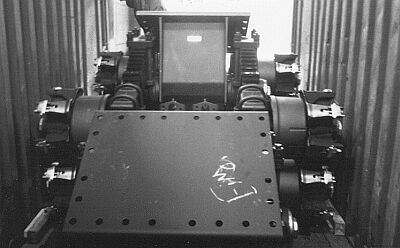

| Packing the first truck axles in the container |

In the foreground of the picture, there is a roll of friction-enhancing material, which has a very high coefficient of sliding friction and is laid between layers. This thin material is not suitable for laying under cargo. Strips of friction-enhancing (FE) mats at least 10 mm in thickness are necessary under the lower layer of axles.

|

|

| Upper part of unsecured stack of truck axles |

Some wooden members used to fix the lower layers are visible underneath. In the upper layers, the friction-enhancing material laid between the layers is expected to provide sufficient stability. This otherwise inadequately secured stack will not withstand extended exposure to bad weather at sea.

Packing the axles centrally, as shown, is unfavorable for securing as the gaps left on both sides must be filled. Alternatively, the entire cargo block could be lashed.

One efficient securing method is to leave gaps towards the container side walls alternately to the left and to the right. In this way, only one gap need be filled in each case.

The sensitive axle heads must be protected. They are in each case packed tightly against the container wall on one side, while the gaps left on the other side must be filled with lumber, airbags or the like.

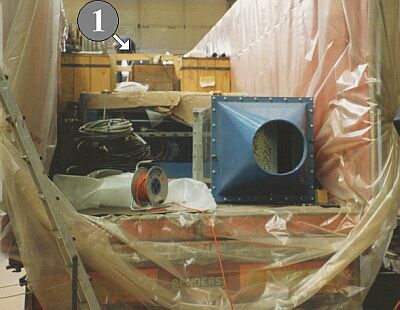

Example 4: Plant parts in a 20' open-top container

In order to provide the plant parts with protection from climatic conditions, the entire container is being lined with 200 µm gage polypropylene film. 200 μm corresponds to a thickness of 0.2 mm.

|

Lining a container with polypropylene (PP) film |

|

|

| View into the partially packed container |

The two wooden cases in the front part of the container are secured with wooden cross bracing. The vertical wooden members could have been dispensed with if wooden members fastened under a board had been suspended in the gap from above.

| Wooden securing member which can be suspended between case lids |

The problem with the planned measures to provide protection from climatic conditions is that desiccant would have to be placed inside the as yet unsealed PP package in quantities sufficient to absorb not only the moisture present in the package but also any water vapor which diffuses in through the film. Lumber, such as the case sides and wooden securing members, normally contains a very large amount of moisture, unless kiln dry lumber is used. The same applies to other packaging containers and packaging aids such as cardboard, paper etc. It is not very likely that the necessary quantity of desiccant will be calculated correctly and actually placed inside the package. The manner in which the other items of cargo have been arranged in the rear part of the container would lead one to suspect that the cargo will not be sufficiently tightly packed.

|

Heat sealing the protective film |

|

|

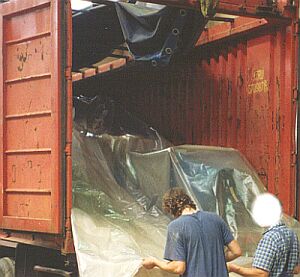

| Packing operations in an open-top container |

This confirms the suspicion - the cargo is not sufficiently tightly packed and secured.

The container could only be considered to be packed in a manner fit for transport once the gaps still present have been completely filled and the heavy parts separately secured.