|

|

| Inadequate packing increases the risk to which the goods are exposed. |

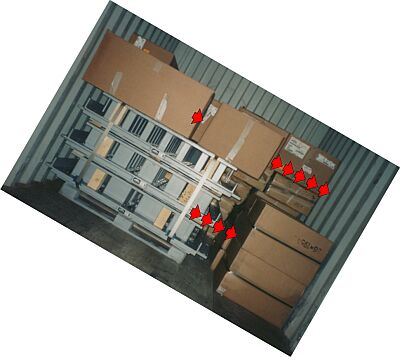

The fact that there is a potential for cargo damage becomes particularly clear if the container is tilted to an angle of 30°.

|

|

... An angle of 30° is enough to get a good part of the cargo sliding ... |

|

This angle corresponds to rolling angles which are to be anticipated in overseas transport or the sideways acceleration forces of 0.5 g to be expected in road and rail transport.

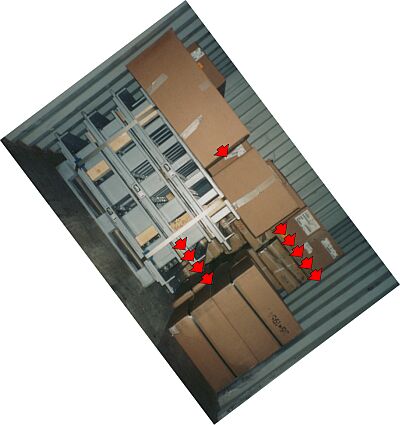

The consequences of inadequate stowage and securing are even clearer if acceleration forces of 0.8 g are presented as a tilt angle of 53°.

|

|

... At an angle of 53°, almost everything will slide ... |

How much of the cartoned goods, truck parts and container will still be usable?

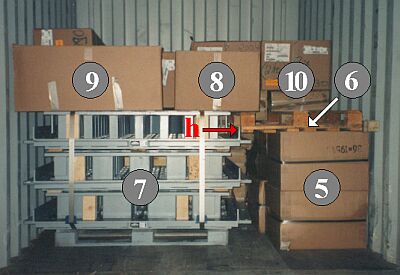

It will take more than putting a pallet on top to remedy the securing deficiencies:

|

|

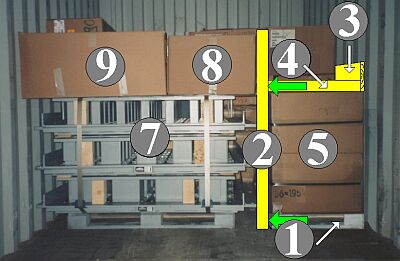

Laying a pallet (6) on top of the cartons (5) is not a satisfactory solution. While the inertia forces generated by the bundled truck parts (7) will be transferred from the point (h) indicated with the red arrow via the pallet to the right-hand container wall, the result will be a point load over a very small effective height against a few container corrugations. The issue of the gaps in the stow between (5) and (7), (8) and (9) and (8) and the right-hand container wall remains unresolved and these gaps absolutely must be eliminated.

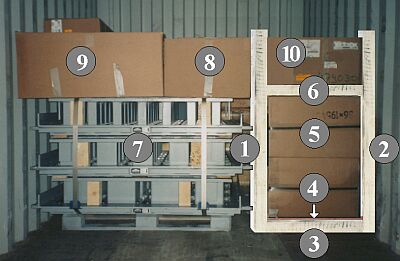

Reasonable securing is not very difficult to achieve:

|

|

| Proposed securing method for truck parts and cartons |

Two u-shaped frames are constructed from two approx. 1.70 m tall squared lumber uprights (1) and (2) together with two cross braces (3), the frames being connected together at floor level with a narrow plywood sheet or wooden dunnage boards (4) laid lengthwise, on which the carton (5) is stowed. The upper parts of the two squared lumber uprights (1) and (2) are braced with two crosspieces (6). The heavy package (7) and the lighter packages (8) and (9) can lean against this structure. Package (10) and other small parts can be stowed "without pressure" and thus protected in the gap between the members (6).

Securing in this manner will even withstand acceleration forces of 0.8 g. There is no risk of cargo damage.

|

|

| Simulation of 0.8 g acceleration by tilting |

Another variant:

|

|

| Alternative securing method for packing truck parts and cartons |

The packages (5) are placed on a pallet and stowed tightly against the right-hand container wall. The gap between the cartons (5) and truck parts (7) is filled with two squared lumber uprights (2) which extend sufficiently far upwards also to be able to prevent packages (8) and (9) from moving sideways. The gap above the cartons (5) is braced with a board (3) laid lengthwise against the container side wall to distribute the pressure and two squared lumber members (4).