|

||

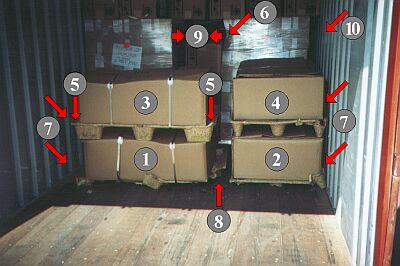

| Damage is inevitable with packaging and stowage like this. | ||

As can easily be seen, the chipboard pallets of packages (1) and (2) have already been severely damaged or completely destroyed before or during container packing. It is clear at (3) and (4) that the pallets do not match the dimensions of the cartons strapped onto them, they extend beyond the edge of the cartons. This is even more clearly visible at (5). The cartons themselves have not been made sufficiently strong for their contents. The strapping has also been applied without sufficient edge protection. The cartons on the wrapped pallets are also very weak. This is clearly visible at (6). Clear violations of the basic rules of packing are present at (7), (8), (9) and (10).

|

||

| Better packing options | ||

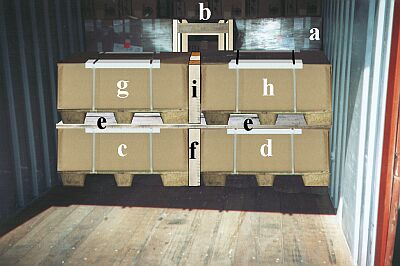

Cargo transport risks could have been mitigated in this way.

The gap at (10) is eliminated by placing the wrapped pallet tightly against the container wall at a. The gap b is braced by means of squared lumber uprights or wooden lattices plus wooden crosspieces. The cartons c, d, g and h are strapped on correctly dimensioned chipboard pallets with sufficiently strong edge protection. The new pallet dimensions mean that now in each case two of them fit crosswise into the container, whereas previously the cartons d (prev. 2) and h (prev. 4) were introduced lengthwise. The slight gap between the cartons or pallets c and d placed flush to the left and right against the container walls is filled with the squared lumber f, with large area dunnage e consisting of boards or slabs being positioned on top. Then the cartons or pallets g and h are loaded and the remaining gap I filled with squared lumber.