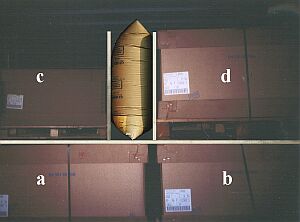

The gap between the upper left-hand package and the container side wall cannot be left as it is. Moreover, no interlayer dunnage has been laid .

|

Gaps in the load constitute a transport risk. |

| Filling gaps with airbags |  |

Interlayer dunnage should be laid between packages a & c and b & d. The inner sides of packages c and d are protected from point loads with sheets or boards and the gap between the items of cargo is filled with an airbag.

In this case too, the gaps in the load can result in damage.

|

|

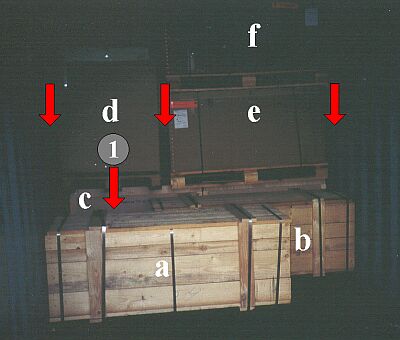

| Gaps in the stow are the root of all evil. |

The gaps behind case (a) and between case (b) and the left-hand container side wall are particularly critical, but the other gaps (red arrows) may also be the root cause of damage. Steps could have been taken to prevent damage by laying dunnage on package (c), onto which packages (d) and (e) could have been placed. No interlayer dunnage would be required between (e) and (f), provided that the bearing area of the pallet-like base is sufficiently large and package (e) is not excessively sensitive.

A good alternative would have been to pack cases (a) and (b) on squared lumber supports placed lengthwise on the right and left of the container. Package (c) could then also have been placed lengthwise in the middle. The squared lumber supports would have had to be dimensioned so as to offset the difference in height between (a) and (b) and package (c). The other packages could then have been stowed on top without further interlayer dunnage in such a manner that they rested tightly against the container walls. The remaining gap in the middle could then have been filled with an airbag or pallet.