|

Packaging and packing deficiencies |

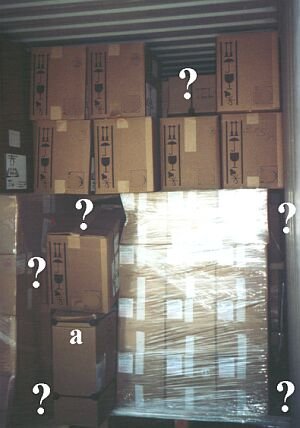

Most of the gaps in the packing are attributable to inadequate packaging and palletization. Package a has been damaged during stowage. Someone has obviously used the carton as a step in order to stow the upper layer of cartons manually.

A better stow could be achieved by unpacking the "palletized" cargo and stowing the packages conventionally.

|

|

| Gaps in the load due to inadequate palletization |

The same problem again: the inadequately packed and wrapped pallets are virtually impossible to secure economically. Unpacking and manual stowing is virtually the only way to secure the cargo sensibly.

As already explained in the packaging section, it is essential

- to select appropriately sized packaging containers,

- to provide pallet bases which are suitable for container transport,

- to provide adequate edge protection when strapping, and

- to provide strong shrink wrapping or other wrapping around the pallets or bases.

The following example reemphasizes these basic rules:

|

|

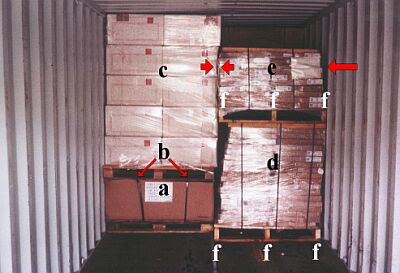

| Packaging and palletization deficiencies promote damage |

Pallets (a) and (c) have been strapped together (b) to form a cargo unit. However, the lack of edge protectors and poor application of the strapping promote cargo slippage. Pallets (d) and (e) are likewise poorly strapped and rest on very "wobbly" feet (f). It is better if the pallet blocks are as wide as possible. Extended periods of bad weather during a voyage make damage virtually unavoidable.

|

|

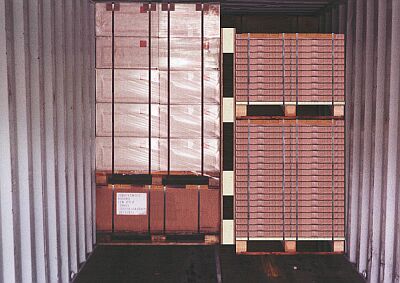

| Proper palletization facilitates container packing and securing of the cargo in the container. |

No changes were made to the cargo dimensions. The cartons were merely set edge to edge and in some cases different pallet bases were used. In this manner, in conjunction with suitable strapping, the cargo can be accommodated securely in the container.

A structure of walking boards and squared lumber offcuts was fabricated outside the container and used to brace the gap remaining in the center of the cargo. The same effect can be achieved with pallets which are no longer required.

|

|

| Apparently insignificant errors can result in major damage. |

The package (a) has not been stowed against the container side wall. Package (b) has only a very small bearing area where indicated. The gap (c) has not been filled. There are similar shortcomings throughout the container. Depending upon the mass and strength of the packages, interlayer dunnage of wooden sheets or boards would be necessary at certain points.