|

||

| Considerable packaging and packing deficiencies |

||

The fundamental deficiencies are:

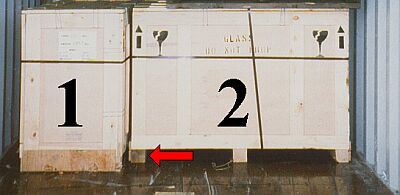

Shipping package 1 can only be picked up with ground conveyors from two sides. With the stowage method illustrated, it was either additionally turned round or it was picked up with the forks under the cross beams, being "pushed in" with the forks between beam and container floor, thereby risking damage to the package and the container floor.

Package 2 lost a wooden member during handling and has been temporarily "jacked up"; in addition it is incorrectly marked: the individual arrows indicate the "top" of this package. Since the contents are made of glass, it must have been to say that the package should be carried upright. However, such a stowage instruction should be expressed by two upright arrows.

|

||

| Unfavorable case skid on 1, broken wooden member and incorrect marking on 2 |

||

|

||

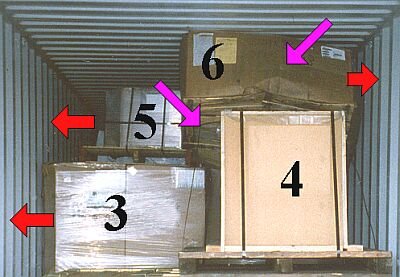

| Incorrectly packed, incorrectly constructed shipping packages | ||

Package 3 reaches down to the container floor and is therefore at risk of tipping. For this reason alone, the gap relative to the container wall should have been filled.

Shipping package 6 was handled "brutally" and was crammed into the container over package 4. Shipping packages 4 and 5 are not suitable for transportation as they are, since both are strapped onto pallets with steel strapping, despite the fact that their dimensions do not allow for flush loading. One steel strap is already torn. In addition, adequate edge protection has not been used.

Fully palletized cargo simplifies packing in containers carrying mixed consignments . However, when properly secured, the packages illustrated here incur higher costs.