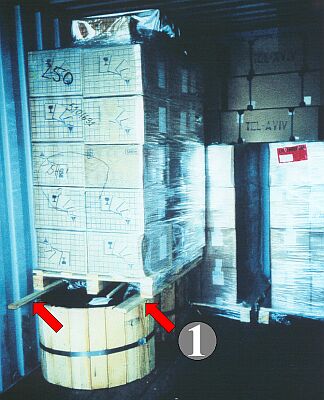

The packing deficiencies at the container end wall are continued throughout. The incompletely packed pallet is not held securely on the cable reel by the interlayer dunnage consisting of two small boards (1) laid lengthwise.

The wooden members should have been larger and laid crosswise (see left).

|

Interlayer dunnage made from strong planks |

|

|

|

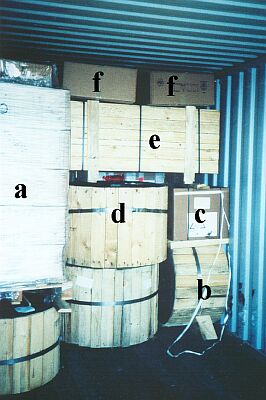

Various packing deficiencies |

|

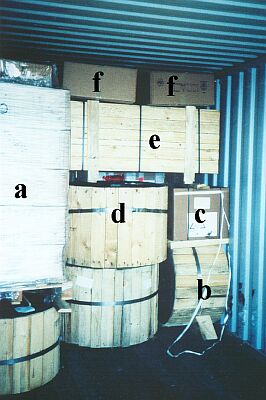

Remedied deficiencies |

|

The method used to pack the container is deficient. However, the interlayer dunnage of planks (1) does give the pallet (a) a secure footing. The cable reel (b) has been stowed with its axis crosswise, which is not very advantageous when it comes to further packing. Even less advantageous is the use of the wedge, which prevents the introduction of further cargo, since additional materials would then be necessary for gap-free stowage. Furthermore, the wedge has been incorrectly cut, since only the end grain is available for nailing. This defect has been corrected at (2): now nails can be hammered into the face grain. The package (c) stands loose on its support and on the cable reel. It could be made reasonably stable by passing the strapping around the wooden skid (3) and stowing the package compactly among other cargo. The package (c) would be damaged by the case (e), a situation which can only be remedied by sufficient interlayer dunnage (4), laid on cable reel (d) and braced against the container wall by boards or the like positioned underneath. If the cartons (f) are very sensitive, interlayer dunnage (5) must be laid on the case (e), though this can be omitted if the box's belt battens are not in a position to damage the cartons. Irrespective of whether or not cartons carry two upright arrows, they should be positioned "right way up" (6).

|