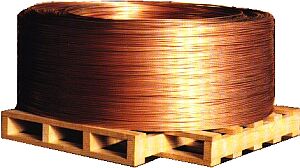

Electrolytic copper coils

Copper wire is denser than steel. A pallet with a coil of 8 mm thick wire with base dimensions of 1.60 m x 1.60 m and a height of 0.70 m weighs approx. 3.5 metric tons. The coils themselves are 1.60 m in diameter and 0.55 m tall.

|

|

| Pallet with copper coil |

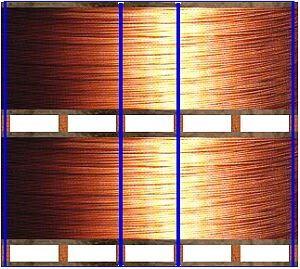

The pallets can be shrink wrapped and strapped for transport purposes. This makes it impossible to secure the coils by loop lashings through the eye. One option for packing in containers is to group together pairs of pallets into an intrinsically very strong transport unit.

|

|

| Cargo unit comprising two copper wire coils |

|

|

| Cargo units secured by shoring |

Warning: Due to the particular shape of the pallets used, particular care must be taken not to damage the copper when driving the wooden members apart. Shoring can only be nailed down into the pallet corner members, while wooden cross pieces cannot be used to fix shoring in place when pallets are flush loaded.

The feasibility of other variants using additional wooden members or similar methods must be assessed on the spot.

With open-top containers, the cargo units can easily be set down on friction-enhancing material, which ensures that only very slight securing forces need be applied. However, if the pallets are pushed into place with forklift trucks, this is not possible. The pallets may, however, be securely shored in place with four dry squared wooden members per pallet. The wooden members required for this purpose rest on the pallet corners which are not occupied with cargo and against the container top side rail between the corrugations. They are driven apart at the bottom and nailed down to stop them slipping back. Alternatively, the wooden members may also be held in place relative to the container sides with strapping or rope.

|

|

| Securing with a special cargo securing tarpaulin |

One option for securing cargo units without using additional wooden members is to use special cargo securing tarpaulins. In this case too it is advisable, where possible, to set the cargo units down on friction-enhancing material.

It is not generally possible to secure such cargoes with loop lashings through the eye as the cargo is generally shrink wrapped on the pallets.

|

|

| Securing with airbags |

Securing with airbags is theoretically feasible, but given the size of the gaps to be filled rather inexpedient. Airbags must not be used in the door area for safety reasons. In order to ensure uniform load distribution, one cargo unit would have to be placed by the front end wall, one in the middle and one flush with the doors of the rear end wall. With pallet dimensions of 1.60 m x 1.60 m, a gap of approx. 0.60 m will be left between the first and second and between the second and third cargo units. This is larger than it is reasonable to fill with airbags.