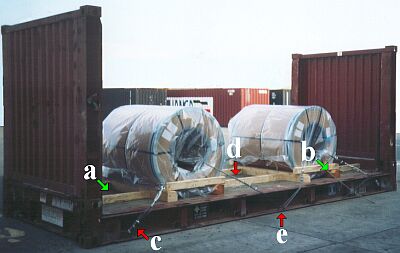

Coils on 20' flatracks

|

|

| Inadequately secured coils on a 20' flatrack |

|

|

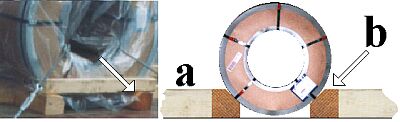

| Wooden beams (a) hold the wedge beams (b) in position. |

Good features include the use of the chamfered wooden members (b) and the fact that these "wedge" beams are held tightly in place by the lengthwise members (a). The steel sheet rolls rest on the wedge beams in such a way that they are not in contact with the floor of the flatrack in the middle.

However, the lashings have been applied nonuniformly. It can be seen at (c) and (d) that only three, i.e. too few, wire clips have been used. At (e), two lashings have clearly been attached to a single lashing point, which does not have the necessary maximum securing load.

|

|

| Coils able to move freely in their lashings |

However, it is the arrangement of the lashings which is particularly disadvantageous as the coils can move freely in the lashings.

|

Coil fixed with loop lashings |

Using loop lashings can prevent the coils from moving sideways.

Depending upon the angle, loop lashings can generate horizontal securing forces in the crosswise and lengthwise directions as well as in the vertical direction. The wooden crosspieces nailed onto the wedge beams can be dispensed with as they are relatively ineffective.

In this case, securing was provided by the above-described method using steel strapping.

|

|

| Each coil is secured with two loop lashings per side. |

Using wedges to retain the wedge members is unfavorable as they are incapable of holding the latter in position over an extended period. It would have been better to use squared lumber bracing.

|

|

| Coil securing with two steel strapping loop lashings on each side |

The path taken by the loop lashings is more clearly visible in this photograph. It would be better to use edge protectors made from segments of used tires. In this way, it is possible to make up for steel strapping's disadvantageously inadequate elasticity. Moreover, the greatest possible protection is provided for the cold-rolled sheet.

|

|

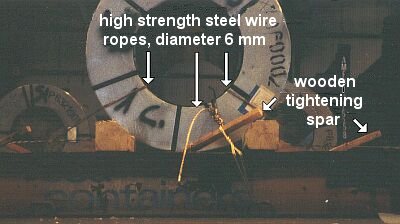

| Coil securing with two 6 diameter steel wire rope loop lashings on each side |

In this case, the coils are located centrally. Otherwise, the above comment applies here too: it would have been better to fasten the wedge members with wooden bracing. This would not generate additional costs. The costs of the wedges are almost the same as for the squared lumber and labor costs are hardly any higher.

|

|

| Tensioning steel wire ropes with a "Spanish windlass" |

In this case, the steel wire ropes have been knotted and pretensioned with tightening spars. Such fastenings can be applied very quickly. The tightening spars must be made from hardwood and must be properly secured against coming undone. Further details may be found in the general section on cargo securing.

|

|

| Detail view of wedge members and steel wire rope lashings |