The loading area should be filled as completely as possible. When the orientation of the corrugations in corrugated board can be determined, it should be taken into account during loading, if possible being kept upright. If this is contradicted by handling symbols such as "Keep upright", the symbols should be obeyed. As early as during preliminary planning, it is possible to calculate the stacking height at which it is possible to achieve a uniform cargo block over the entire length of the container. Depending upon the strength of the cartons, interlayer dunnage may have to be used. In the case of very weak cartons, the interlayer dunnage may be supported like a "false deck". If gaps occur during packing, they must be filled immediately as it will not subsequently be possible to reach the gaps without damaging the cargo. Stacking in an interlocking pattern is sometimes recommended. In the present author's opinion, this is inadvisable because higher levels of strength are achieved if the outsides of the cartons are arranged perpendicularly one above the other. An interlocking stow is better achieved by using anchors of kraft paper, grayboard or similar material.

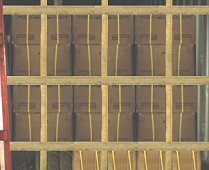

Any remaining gaps in the door area can be filled with wooden lattices and squared lumber bracing against the corner posts.

|

|

||

| How it actually was ... | ... and how it could have been! |

|

Manual packing of cartons and trays |

|

|

|

| Even with "big cartons" the gaps must be filled. | ||

|

|

|

| Compactly packed container | Securing in the door area with a lattice |