Two crates made from steel angle sections on a 40' flatrack

|

This flatrack is loaded with two crates made from steel profiles. Wooden bracing has been positioned against the end walls to provide lengthwise securing. Lateral securing was provided for the longer crate in the form of four tie-down lashings and for the shorter crate in the form of two tie-down lashings made from steel wire ropes 16 mm in diameter.

|

|

|

| Waste of materials due to nonuniformity of lashings | ||

With a 16 mm steel wire rope, a maximum securing load of at most 10,240 daN can be achieved per single run. These values are reduced as a result of small deflection radii, using fewer than 4 wire clips, angles of spread (such as the 120° here) and similar factors. The lashing points probably have a maximum securing load of approx. 3,000 daN. A not inconsiderable amount of material has consequently been wasted. When selecting the lashing materials, the lashing personnel should have ascertained the maximum securing load of the lashing points.

|

|

|

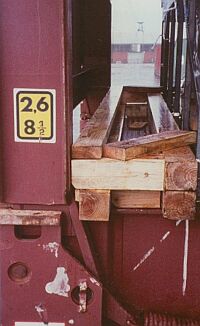

| Expert bracing at the ends | ||

The bracing against the corner protectors of the flatracks does not merit any criticism. The use of the small board at (1) constitutes a minor defect and reduces the effective cross-sectional area of the bracing a little.

|

|

| Transverse securing using loop lashings at floor level - end-on view |

|

|

| Transverse securing using loop lashings at floor level - plan view |

The most favorable force components for good transverse securing can be achieved by loop lashings. The maximum securing load of the lashing wires, lashing belts or other securing materials can be doubled by positioning the ends at separate lashing points. By laying friction-enhancing materials under the steel crates, the total securing forces required can be reduced.

|

|

| Direct lashing against tipping |

Rather than tie-down lashings, direct lashings should be used against tipping. Depending on the strength of the crates, these do not necessarily have to extend as far as the upper side rails, but can be attached lower down.

|

|

| Unfavorable securing using diagonal lashings (cross lashings) |

Cross lashings as shown have both corresponding transverse and vertical components. Nevertheless, the other methods described above (for separate application) are preferable to this combined method.

|

|

|

| Diagonal lashings are virtually incapable of preventing tipping. | ||

The Figures show that cross lashings are virtually incapable of preventing the shipping packages from tipping.