Crate made from steel angle sections on a 20' flatrack

|

||

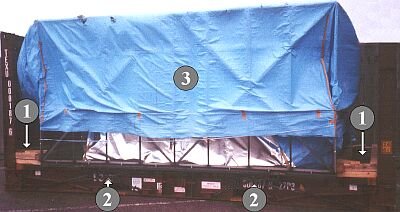

| High-quality machine in a steel crate on a 20' flatrack | ||

|

|

|

|

|

|

| For clarification, the details from the picture which bear numbers 1 and 2 are shown at an enlarged scale. | ||

A high-quality machine heat-sealed into a sealed package to protect it from corrosion is being transported in the crate. In principle, the sensitive sealed packages should be protected by a closed container or a case. In this case, loading in a closed container is out of the question because of the dimensions of the package. Therefore, stowage in a case with sufficient load-carrying capacity is essential.

|

|

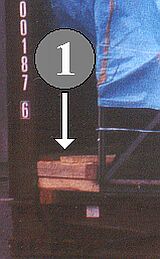

| Above and right: very small contact surface of the wooden bracing |

|

The lengthwise securing of the crate on the flatrack merits criticism insofar as only very narrow strips (1) of the steel angle sections are used as an effective area for bracing.

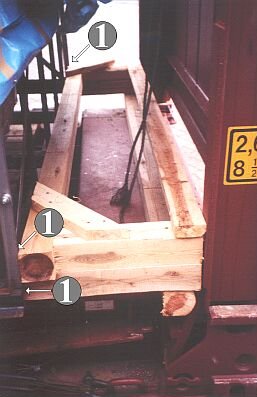

This may be the reason why steel wire ropes 16 mm in diameter are additionally used, together with turnbuckles and shackles, for lengthwise securing to prevent forward movement (2) and backward movement (3).

What is completely lacking is transverse securing of the crate.

|

|

| Lengthwise securing of the crate by steel wire lashings |

|

|

| Desirable steel crate base - plan view |

So as to provide sufficiently large surface areas for bracing, flat steel profiles should be selected at the ends (a). For greater rigidity, diagonal stiffeners should be fitted (b).

|

|

| Lengthwise and transverse securing of the steel crate at floor level - illustrated without the cargo for greater clarity |

The steel crate may be easily braced lengthwise with wooden members, if appropriately constructed. Transverse securing may be effected at floor level by loop lashings, which are applied to the outer beams. Depending on the strength of the crate components, further loop lashings may be fitted.

Additional securing against tipping is recommended at the ends of the crate in the form of tie-down lashings or "cross lashings".