Single case on a 20' flatrack

|

|

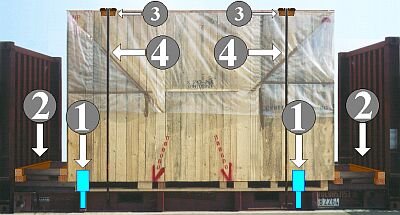

| Inadequate packing of a 20' flatrack with an overwidth case |

A few hints are required with regard to packaging and securing. The standards state that marking should preferably be in black and expressly prohibit the use of scarlet.

|

|

||

| Unclear marking | Correct marking |

The single arrow symbol (a) with the word UP is not standard. As an abbreviated version of "This way up", it means that the case should be carried upright, which is normally symbolized by two upright arrows.

|

|

||

| Inadmissible color: scarlet |

Admissible color: black |

The incorrect choice of color for the symbol (b) is of course a minor defect. What is more important is that the case, which needs to be kept dry, is only partially covered with a simple PE film 200 μ thick. This film will definitely not keep the package dry during a voyage, especially not if the flatrack is stowed on deck. Depending on its stowage space, the film will be damaged by exposure to the wind and possibly also by solar radiation.

| Correctly affixed information marks |

|

The symbols relevant to handling of the case should be affixed together as far to the top right as possible on two sides, which again is not the case here.

The marking relating to slinging of the case (c) is not standard either, but the least favorable feature is that the case has been so constructed that the slinglift points lie very close together and there is a risk that the case may fall out of the slinging means. There is no need to go into this unnecessary cargo handling risk.

|

|

| Red: unfavorable slinglift points Black: favorable slinglift points |

At (d), the mass of the case is stated as 4600 kg. Calculation of the moments shows that the center of gravity of the packed flatrack is more than 60 cm away from the middle of the flatrack, which is inadmissible.

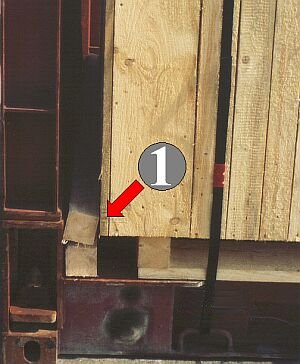

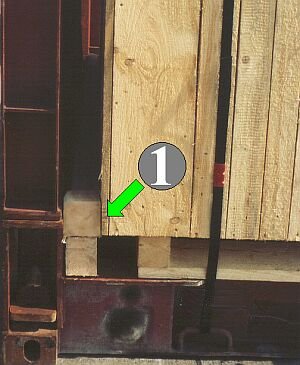

The cargo securing is inadequate. The crosspiece (1) is too low - it does not lie with its whole height against the bottom of the case. Other shapes or the additional use of a board could put things right.

|

|

| Incorrect position of the squared lumber |

|

|

| Correct position of the squared lumber |

The cross piece (3) is correctly positioned, and transmits the forces into the case bottom:

|

|

| Correctly positioned crosspiece for lengthwise securing (green light) But: inadequate transverse securing (red light) |

The lengthwise wooden members (2) are correctly positioned, but apply point loads to the end wall of the flatrack at (4).

|

|

| Point-loading of the flatrack end wall by the lengthwise wooden members |

An additional squared lumber member fitted against the end wall can effect pressure distribution.

|

|

| Correct pressure distribution by an inserted crosspiece |

The tie-down lashings (5) are stretched over the case top and film without further measures. They are already cutting visibly into the lumber and damaging the film and will not in the long term retain the pretension required for securing. The problems with using tie-down lashings on overwidth packages have already been discussed.

Appropriate securing might have looked like this:

|

|

| Correct securing of the overwidth and overheight case |

The shipping package is loaded centrally. The overwidth case is secured laterally by special "case restraint shoes" (1), the design and mode of action of which will be described below, with possible alternatives. Lengthwise securing is achieved with wooden bracing (2), which consists in each case of two crosspieces and lengthwise members, which are "chocked up" far enough for them to transfer forces in the area of the case bottom.

The two steel strapping tie-down lashings (4) are designed to hold the case in the "case restraint shoes". In order to protect the case and ensure their efficacy, they are tensioned over cornerpieces of elastic material (3).

|

Expert bracing |

To shore the case, squared lumber of rectangular cross-section is selected (1), whose narrow side matches the height of the "case restraint shoes". The wooden members are positioned crosswise in front of the case and the flatrack end wall. On these are laid square or rectangular lumber (2), whose dimensions are somewhat smaller than those of (1). It is important for the wooden members (2) to be able to rest against load-bearing parts of the case, the best place being the bottom area of the case. Squared lumber (3) is fitted between these wooden members and lies on the protruding part of the wooden members (1).

To ensure securing of their own product, the exporting company should provide "case restraint shoes", given that they know that their case is an overwidth case and will have to be transported on a flatrack.

|

Case restraint shoes |

The case restraint shoes may be easily made from flat or profiled steel. The distance between the upper lugs (1) must match the width of the case, that of the lower lugs (2) the width of the flatrack. At least two of these shoes are positioned on the flatrack at suitable points and the case is loaded onto them.

| Tight-fit lateral securing of a package in case restraint shoes |

|

|

|

Longitudinal planks between case and case restraint shoe |

It is important for the lugs of the case restraint shoes to be "meaty" enough to hold the case. Slight dimensional tolerances between the lugs of the case restraint shoes and the cases can be compensated with hardwood driving wedges.

It would be better and more favorable if flatracks with stanchion pockets were commercially available which carried a corresponding number of different-sized specially shaped stanchions. This would markedly improve and rationalize the securing of many cargoes.

| Specially shaped stanchion for a 20' flat - for insertion into stanchion pockets |

|

|

|

| Use of two specially shaped stanchions for securing a case on a 20' flatrack - crosspieces are positioned beneath the case to prevent its bottom from sagging |

In the case of cases with transverse skids, crosspieces or lengthwise members corresponding in height to that of the horizontal specially shaped stanchion components should be laid under the case bottom to support it against sagging (h).

|

|

| Measure taken against sagging of the bottom: lengthwise wooden members laid thereunder |

|

|

| Measure taken against sagging of the bottom in cases with longitudinal skids: crosspieces laid thereunder |

Firring should also be provided in the case of cases with longitudinal skids, if the outer longitudinal skids stand on the specially shaped stanchions.

|

|

| No measures need be taken against sagging of the bottom, if the case restraint shoes apply load to the load-carrying parts of the flatrack. |

Firring can be omitted if the longitudinal skids are free of the specially shaped stanchions and the load is evenly distributed over load-carrying container components.

To hold the packages in the case restraint shoes or specially shaped stanchions, at least two tie-down lashings are also fitted per shipping package.

|

|

| High quality securing of a case using case restraint shoes and tie-down lashings |

The tie-down lashings act in this and similar cases to prevent "popping out" of the case restraint shoes or specially shaped stanchions under dynamic loads. They are actually being used here as direct lashing.