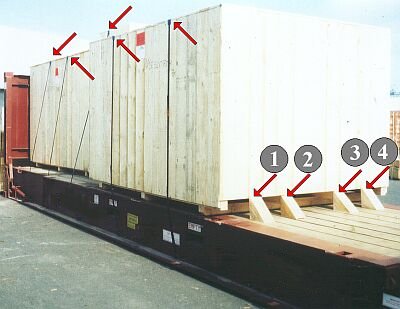

Inadequate load distribution and securing of three wooden cases on a 40' flatrack

|

|

| Incorrect load distribution and inadequate securing |

Steel strapping tie-down lashings have been fitted. Since simple plastic cornerpieces have been used, the steel strapping will press into the wooden boards of the case top under load and its pretension will gradually diminish, resulting in the loss of its securing action. With a steel strapping lashing length of 7 m, pretension would drop to zero if the strapping were to press into the top boards by only approx. 10 mm.

Another problem is that the front case is overwidth and is nonetheless secured with tie-down lashings.

Securing by the wedges nailed in front of the cases has virtually no effect, since the effective height of wedges (1) and (4) is minimal and that of wedges (2) and (3) immaterial.

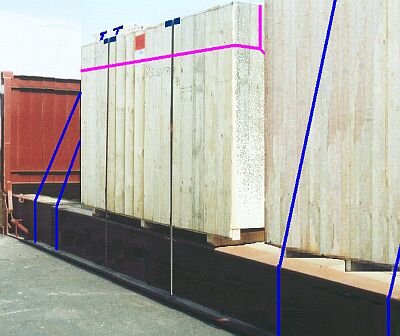

Use of very close fitting wooden bracing ensures adequate lengthwise securing:

|

|

| Using wooden bracing instead of wedges |

|

|

| Options for maintaining pretension |

Heavy-lift cornerpieces, as shown at (1), are rigid and allow prestressing forces to be maintained under favorable conditions. It is better to use edge protectors of a resilient material with good recovery properties - such materials, as with a piece of tire at (2), allow maintenance of pretension under usual carriage conditions.

The load distribution on the flatrack contravenes the regulations outlined in particular in the CTU packing guidelines, which state:

| 3.2.5 The weight of the cargo should be evenly distributed over the floor of a container. Where cargo items of a varying weight are to be packed into a container or where a container will not be full (either because of insufficient cargo or because the maximum weight allowed will be reached before the container is full), the stow should be so arranged and secured that the approximate center of gravity of the cargo is close to the mid-length of the container. If it is not, then special handling of the container may be necessary. In no case should more than 80% of the load be concentrated in less than half of the length of a container measured from one end. For vehicles, special attention should be paid to axle loads. |

|

|

| Acceptable packing and securing of the flatrack |

By calculating the moments, the best position may be determined for the cases. The Figure shows roughly how they might be packed and secured:

- All the cases are positioned on strips of friction-enhancing material.

- The heavy overwidth case is positioned in such a way that the center of gravity lies approximately one meter to the left of center. It is secured against lateral shifting and tipping by using spring lashings with two direct lashings.

- The lightest, tall, slim case is packed to the left thereof and blocked against the end wall.

- The medium-weight case is positioned in front of the overwidth case and braced against the other end wall.

- Each case has two tie-down lashings.