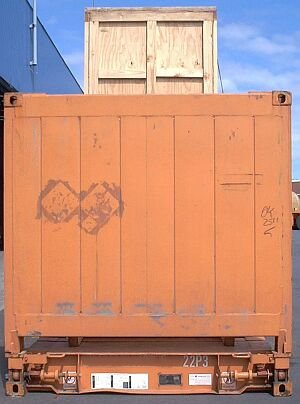

Two overheight wooden cases on a 20' flatrack

|

|

| Inadequately secured cases |

The two cases are "secured" in the floor area by wooden members nailed in front of them, or "wooden fixings", only the shearing forces of the nails being capable of furnishing any resistance against shifting.

|

|

| Inadequate securing with wooden fixings |

The cases are more than three times as tall as they are wide, so, given their small standing area, they are at any rate to be classified as at risk of tipping. Two tie-down lashings per case are not enough to make them safe.

|

|

| Two tie-down lashings per case cannot prevent them from tipping. |

This is particularly obvious if the flatrack is inclined sideways by 30°.

|

|

|

| Case at risk of tipping, inclined by 30° | ||

The container type 22P3 used has four stanchions on each side, each with a loading capacity of 2,000 daN. Relatively low mass cases are therefore easy to secure.

|

|

| Cases secured in the floor area against stanchions and flatrack end walls |

A total of eight struts are built each from two boards (1) and one squared lumber member (2) and are placed between the stanchions and the boards (3) positioned in front of the cases.

|

|

| Securing the cases transversely - end-on view - details |

Reasonably priced, unsquared boards can be used as the transverse (1) and vertical boards (3), while the sizes of the transverse braces (2) should be matched to the stanchions (4) from the point of view of width. Their height depends on the masses to be braced.

|

|

| Securing the cases longitudinally - plan view - details |

At each end of the cases, a squared lumber member or a beam (4) is firred in such a way that it lies horizontally at the level of the sufficiently strong case bottom. A squared lumber member (5) is raised in such a way at the ends of the flatrack that it is at the same height as the squared lumber member (4). These squared lumber members serve to distribute pressure to the flatrack end walls. Other squared lumber members are fitted precisely between the squared lumber members or beams (4) and (5) in parallel with the longitudinal sides of the cases. These members may either be built up from the bottom (6) or suspended on boards nailed over them (7).

|

|

|

| End bracing built up from below (6) | ||

|

||

| End bracing with suspended bracing members (7) | ||

|

||

| Securing against tipping by bracing against the stanchions |

||

Lateral securing against tipping is provided approximately half-way up the package by bracing similar to that in the floor area. Eight bracing members are constructed from two boards (11) and one squared lumber member (10). These are held in place by squared lumber (9) attached vertically to the inner edge of the stanchions and boards (8) nailed horizontally to the uprights (3).

Two tie-down lashings are applied per case for the purpose of stabilization and to prevent "popping out" of the bracing under dynamic loads. At the case edges, the steel strapping lashings are tensioned over automobile tire segments, in order artificially to improve the elasticity of the steel strapping and to be able to maintain the pretension.

|

Automobile tire rubber improves elasticity and maintains pretension in steel strapping lashings. |

Efficient securing options are achieved if special devices are available for cargo securing.

| Transverse securing in the floor area by specially shaped stanchions Securing against tipping using a steel crosspiece and direct lashings |

|

In the floor area, specially shaped stanchions can be used to secure the cases transversely either directly (1) or indirectly by using squared lumber, planks or boards (2). Securing against tipping may be achieved using direct lashings (4) passing via steel crosspieces (3).

Steel crosspieces should have appropriate lugs or angles which are capable of gripping the tops of the cases. Appropriate lashing bars, lashing rings, holes or similar components must be present, in which lashing materials such as steel wire ropes, chains, webbing belts etc. can be fastened directly or indirectly using shackles, hooks or other components. It would be sensible for such aids to be supplied directly by the producer or packer - the small expenditure should be worthwhile.

| Steel crosspiece incorporated onto the case top |  |

Integral lashing points should be provided as standard on large or heavy cases, since the small additional cost is more than justified by the considerably reduced shipping risk.

|

|

| Specially shaped stanchions as transverse securing in the floor area, direct lashings for lengthwise securing and securing against tipping |

The effort involved in securing using specially shaped stanchions and direct lashings is minimal. In the floor area, the cases are secured transversely by specially shaped stanchions (1 and a). The means of securing against tipping (e) are fitted to affixed or integral steel crosspieces or lashing points (d). Lengthwise securing is achieved by direct lashings (f), which are held at an appropriate height at the case corners by the vertical components of the specially shaped stanchions.

From the standpoint of labor costs, building wooden bracing (c) for lengthwise securing is more costly:

|

|

| Specially shaped stanchions as transverse securing in the floor area, direct lashings for securing against tipping, bracing as lengthwise securing |

|

|

| Specially shaped stanchions and laterally fitted wooden members as transverse securing in the floor area, direct lashings for securing against tipping, bracing as lengthwise securing |

If the dimensions of the specially shaped stanchions and cases do not allow a direct tight fit, the gaps must be filled with squared lumber (b), planks or boards. Small stowage gaps can be filled with driving wedges.