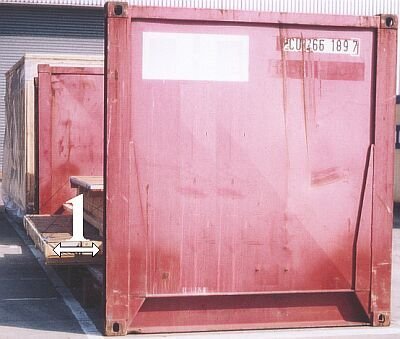

Three flat cases on a 20' flatrack

It is impossible to secure laterally overhanging cases with tie-down lashings, since the cases can move freely to and fro in the tie-down lashings (1). Lengthwise securing with nailed-down lumber (2) is worse than useless and cannot prevent shifting in the longitudinal direction; indeed, not only that, but nails hammered into the outside of the cases may damage the goods. The nailed-down wedges (3) are not capable of providing adequate securing against shifting, either. To sum up: Labor and material have been wasted, to no avail.

|

|

| Inadequately secured cases on a 20' flatrack |

|

|

| Tie-down lashings cannot prevent shifting in the case of overwidth cases |

The following procedure could have been followed, to achieve optimum stowage and securing:

|

|

| Step 1: Central loading of large overwidth box |

|

|

| Step 2: Central loading of flat, shorter overwidth case |

The shorter, flat overwidth case is loaded as second package. So that it is not damaged by the case to be loaded thereafter, on the one hand, but can be secured jointly with the case loaded first, on the other hand, a wooden frame is built around the case, the height of which matches that of the flat case.

|

|

| Step 3: Building a wooden frame round the flat case |

Before loading can continue, these two cases are secured against sideways shifting with "true loop lashings" (half loops). The blue loop lashings (1) and (2) secure the cases on one side, the purple loop lashings (3) and (4) on the other.

|

|

| Step 4: Lateral securing of the overwidth cases using loop lashings |

The narrow case is placed centrally on the two laterally secured overwidth cases and secured against lateral shifting by two loop lashings on each side. These "half loops" are light green and dark green in the Figure.

|

|

| Step 5: Loading and subsequent lateral securing of the large, narrow case by two loop lashings on each side |

The cases are secured jointly against the end walls of the flatrack using wooden bracing, which consists in each case of two "uprights" at the case sides and end walls with bracing fitted in between.

|

|

| Step 6: Lengthwise securing of the cases using squared lumber bracing |

|

|

| Step 7: Securing of the squared lumber bracing with wooden X-bracing, if there is concern that the wooden bracing members may become dislodged |

N.B. So as to be able to work as quickly and efficiently as possible, the loop lashings are each attached at one end to the corresponding lashing points before loading.