|

|

|

| Transverse securing | Lengthwise securing |

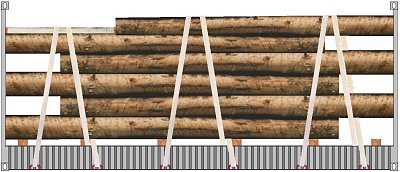

If lashing rings with an MSL of 6,000 daN are available and chains of a similar grade are used as loop lashings, a 24,000 kg block could be secured with two loop lashings against acceleration of approximately 1 g. Wooden bracing can be used in the lengthwise direction.

|

|

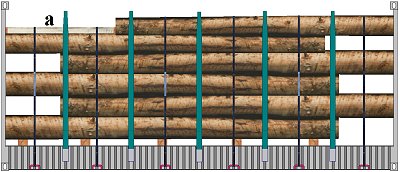

| Staggered - wedged together - top gap blocked |

The logs were positioned alternately with their thick ends against the end walls, resulting in wedging together of the lower layers. Of course, this only works if the end walls are sufficiently strong. The gap in the top layer is braced (a). In the case of flatracks with stanchions, lashings can be used. Securing with steel strapping is acceptable, if the stanchions are lashed together transversely. However, it is to be expected that the steel strapping will slacken. A resilient material would be better. If tie-down lashings are used, the logs can even be loaded without any transverse underlays. These cannot be omitted if loop lashings have to be used for securing due to a lack of flatracks with stanchions.

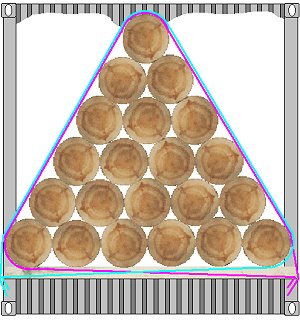

This works if the logs are loaded in the cantline.

|

|

| Lateral securing using loop lashings |

|

Logs packed in the cantline in pyramid stow and secured with loop lashings |

|

|

| Roundwood cargo on a 40' flatrack with stanchions |

Although this roundwood cargo is properly secured, too much effort has been put into lengthwise cargo securing, since the wooden bracing at the ends requires a lot of work and material. The securing used at the ends consists of vertical squared lumber, to which boards have been nailed crosswise in the form of a lattice. Squared lumber braced lengthwise between the vertical squared lumber lies on each of these boards. The logs have been packed in such a way that they rest with their largest diameter on one another and against the stanchions, so meaning that they are not positioned in the cantline directly against the stanchions. The maximum securing load of the blued 1.6 mm x 32 mm steel strapping matches that of the lashing points.

The stanchions, which are bound together in the transverse direction, effect transverse securing. Steel strapping effects vertical securing. Slack is to be expected in the steel strapping. Load distribution still falls within legally admissible limits, despite the fact that the thick ends of all the logs point in the same direction.

The following variant is somewhat cheaper but still very complex. Load distribution is definitely within regulatory limits.

|

|

| Load distribution good - cargo securing effort high |

Prior to packing, a lattice of squared lumber and boards is prepared and so dimensioned that the logs on the flatrack are still caught by the stanchion furthest to the left. The lattice is placed against the right-hand end wall and the logs are stowed tightly against it. The gap to the left is braced by two lattices plus squared lumber. As before, steel strapping is used for securing.

|

|

||

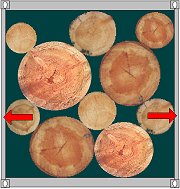

| Correct stowage | Incorrect stowage |

When stowing logs in box containers, it must be noted that the logs directly or indirectly load the container walls due to the angles of spread or rest. The logs must be packed tightly against the end walls and so as not to overload the side walls. Gaps at the door end must be braced.