|

|

|

|

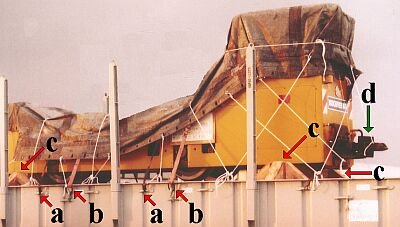

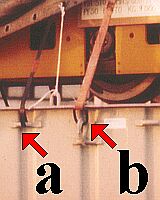

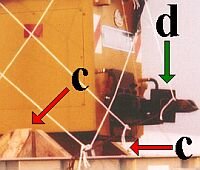

| Top and selective enlargements below: Inadequate securing of a rail vehicle |

||

The vehicle cannot be held securely by the four tie-down lashings applied. Two consist of steel strapping (a) and two of textile belts (b) from the lashing reels fixed to this flatrack. The wooden wedges (c) do not have any great securing effect.

This example gives cause for much criticism:

- Although the manufacturer of the flatrack has installed lashing reels, they are all on one side and can only be tensioned in the transverse direction. If the lashing reels had been installed evenly or alternately on both sides, the vehicle could have been secured against transverse acceleration with two loop lashings on each side. If the structure of the reels allowed the lashing means to be tensioned in the longitudinal direction or obliquely as well, securing against forces in this direction would have been possible.

- The manufacturer of the vehicle omitted to install appropriate lashing points on the vehicle. The apparatus cannot be deemed fit for transport without them. Their provision would result in a marked reduction in the risk of damage during transport.

- It is clear from the securing provided that the packing company used untrained personnel.