|

||

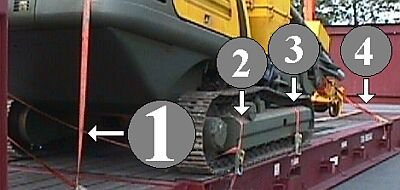

| Inadequately secured earth borer on a 40' flatrack | ||

It is obvious, even at first glance, that the earth borer is inadequately secured and its center of gravity is eccentrically positioned. The apparatus will slip during road or terminal transport and, unless improvements are made, there will be an acute risk of damage during a voyage.

|

||

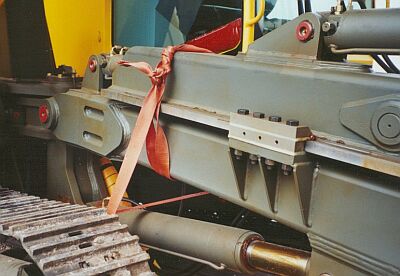

| Top and selective enlargement below: Loosened, slipped lashing belts |

||

The lashing belts (1) and (4) have clearly slackened. The lashing belts (2) and (3) have tightened up due to displacement of the machine.

|

|

|

| Ineffective, incorrectly applied lashing belt | ||

The way the belts have been applied, they are capable of absorbing virtually only vertical securing forces and act only against upwards movement. It is incorrect to pass belts through the louvers in the engine compartment cover serving as a counterweight in such a way that they are constricted and thereby weakened. The fittings on the belt are not entirely suitable for attachment to the steel stirrups visible on the flatrack.

|

||

| Lashing belt weakened by sintering | ||

The lashing belt (2) has been stretched by the movement of the earth borer on the flatrack. Slippage produced so much energy that paint was rubbed off and the belt material was damaged by frictional heat. Allowing stones to get under the belt is sloppy practice and could weaken the belt. The fact that the appliance has already slipped during precarriage shows that the tie-down lashings used for cargo securing were unsuitable.

|

Lashing belt weakened by slippage |

Lashing belt (3) also shows slight damage due to shifting of the earth borer caused by inadequate securing.

|

||

| Inadequate securing of the boring arm by a round-turn lashing | ||

A part can move relatively freely in a round turn. In this case, the boring arm can consequently move easily to the left and right, if it is not prevented from doing so by a bolt in the turning gear. This deficiency could be remedied by two loop lashings.

|

|

Above and selective enlargement to the left: Incorrect use of lashing belt (5) |

|

||

| It is forbidden to knot lashing belts. | ||

If lashing belts are knotted, up to 70% of the admissible lashing force Fadm or the lashing capacity LC stated on the belt label is lost. Even specialists don't know what strength is actually left.

|

|

|

| Misused and appropriately used lashing hooks | ||

The lashing hook of lashing belt (5) has also been incorrectly used. It is not intended to be used in the manner illustrated on the left. If the opening in the hook is big enough, the hook can be used as illustrated on the right. The load borne by the hook must be applied to its base.

The manufacturer of the earth borer has not taken any precautions with regard to cargo securing, despite being well aware that the machine does not travel to its purchaser or place of use on its own tracks. Cargo securing is therefore particularly difficult and risky. Cargo securing personnel seldom know which parts of the machine can be loaded to what degree and in what manner and such information can often be difficult to obtain. The following recommendations for appropriate securing are therefore made with reservations and without any guarantee that they are correct:

|

||

| Basic principles of securing the earth borer | ||

Appropriate longitudinal securing means (purple), transverse securing means (blue) and vertical or anti-tip securing means (green) must be provided, in addition to appropriate load distribution. The following more detailed options are feasible:

- The earth borer is positioned on the flatrack in such a way that the overall center of gravity of the machine lies as far as possible within the central longitudinal and central transverse line of the flatrack.

-

Sufficient longitudinal components need to be produced for cargo securing. To this end, as indicated by purple lines, lashings are attached to the inside of the tracks with sufficiently broad fastening elements and tightened in the longitudinal direction of the flatrack with as flat as possible lashing angles. As an alternative, bracing could be provided between the earth borer and the ends of the flatrack. Given the large distances to the end walls, this method is only economic if no lashings have to be attached to the tracks.

- Sufficient transverse components need to produced for cargo securing. To this end, as indicated by blue lines, lashings are attached to the inside of the tracks with sufficiently broad fastening elements and tightened in the transverse direction of the flatrack with as flat as possible lashing angles. Before the tracks are used for load securing, it should be clarified in each individual case with the manufacturer of the construction machinery whether they can withstand the loads applied by load securing. To secure the boring arm, appropriate loop lashings need to be selected which are passed in each case from right to right and left to left to separate lashing points. As an alternative, lateral securing is possible by inserting the stanchions of the flatrack in the area of the tracks and bracing small gaps between tracks and stanchions with boards.

- To secure against tipping, appropriately shaped fittings can be hooked into the solid metal louvers of the engine housing. Direct lashings are hooked into these fittings to secure against tipping and vertical movement.

If the manufacturer of the earth borer had provided adequately sized lashing points on the running gear, the counterweight with engine housing and the boring arm, appropriate securing could easily have been achieved.

|

||

| Problem-free securing of an earth borer suitably designed for transport | ||