|

||

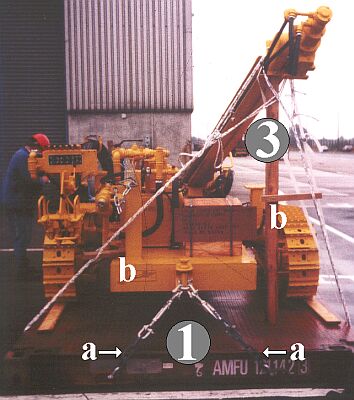

| Earth borer on platform | ||

The running gear was secured at the rear (see next Figure) with turnbuckles used as diagonal lashings and (see Figure above) to the tracks by means of oblique and diagonal lashings consisting of steel wire rope (1). The lower part of the boring mechanism was secured with diagonal lashings consisting of shackles, turnbuckles and steel wire ropes (2). The boring arm was fixed at the rear (3) and front (4) by applying Spanish windlasses to oblique lashings consisting of "Hercules" rope interwoven with polypropylene.

|

|

|

| Inappropriately fitted lashings (2) | ||

The lashings (2) are inappropriately fitted. It is clear that the turnbuckles are stressed to the point of slight bending. Although, in this case, this does not impair safety, it may prevent the turnbuckles from being reused subsequently. It would have been better if, as in the next picture at (1), the turnbuckles had been attached to the lateral frame of the platform using chain links, i.e. in this instance small pieces of high-strength, long link chains (a). If deflections around sharp edges are necessary, short link chains would be more appropriate, because they would not then be stressed by bending. However, they can only be used as high-strength chains in conjunction with special end links, since no suitably strong shackle can be screwed into short link chains.

|

||

| View of the back part of the secured earth borer | ||

The selected lashing angles of the lashings (1) are very well balanced. They provide markedly uniform transverse, longitudinal and vertical components. The lashing angles of the lashings (3) of the boring arm, on the other hand, have an uneven effect. Different positioning of the boring arm was not possible, however.

In this case, securing is only insignificantly impaired thereby, since the lashings (4) produce adequate transverse components for lateral securing of the boring arm. Positive features of the previous Figure are the positioning and fastening of the tightening spars (b): they are prevented from coming undone.

|

||

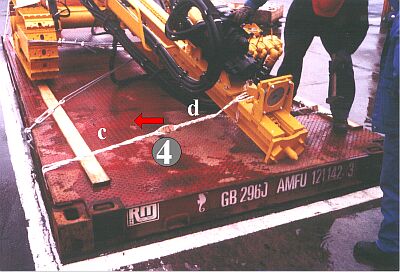

| Earth borer on platform - view from the other longitudinal side | ||

Things are different on the side of the lashing (4) facing the direction of view. Here the tightening spar should have been positioned a little further to the left.

|

||

| Tightening spar position at (4) in need of improvement | ||

At (c), the number of turns is distributed over a greater length than at (d). Moving the tightening spar a little to the left would have produced more even turns and firmer positioning of the tightening spar.

|

||

| Wire rope lashings attached to the tracks | ||

|

||

| Correct wire rope shear | ||

The type of shear ensures that the full maximum securing load of the wire rope is retained at the sharp edge because four working parts are produced which each provide 25% of the full strength.

However, a possible criticism is the thickness of the wire ropes used. Since the maximum securing loads of the lashing points present ranged from 3,000 daN to 4,000 daN, material is wasted by using wire ropes with a diameter of 16 mm, since maximum securing loads of 10,240 daN can be achieved with such wire ropes.