- EVO - § 2 - Stowage

- The objects to be loaded must be fundamentally safe and secure and should not be able to move as a result of jolts or vibrations that can be expected under normal operating conditions. The possibility of longitudinal movement is permitted insofar as the magnitude of this movement is limited by the use of appropriate means and there is no risk posed to safety.

|

|

The sliding loading method allows cargo to move in the direction of impact as a result of the jolting forces that occur during rail transportation. With this method, jolting energy is absorbed by friction work. The magnitude of deceleration in g (1 g = 9.81 m/s²) corresponds to the size of the friction coefficient between the package and the loading surface. The lower the friction coefficient, the lower the forces acting on the cargo, but the greater the travel and vice versa. As a result of the limited travel which is possible, this method is geared toward the friction between wood and wood with travel of at least 1.5 m on each side of the object. If the possible travel is less than 1.5 m, then the use of non-slip materials placed between the load and the floor of the freight car is required.

The German railroad authorities recommend the use of this method for sensitive loads, for example, machines etc. if the properties of the load and the length of the loading area permits the method and if the goods are not in danger of tipping. The lower end edges of the load should be beveled in order to ensure that they do not snag on uneven areas of the freight car floor. If the bottom surface of the goods does not allow them to slide, they should be firmly attached wooden skids or sleds. The leading edges of the skids should be shaped like runners.

|

|

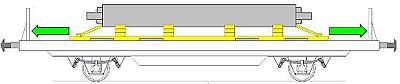

| The sliding loading method - Side view |

|

|

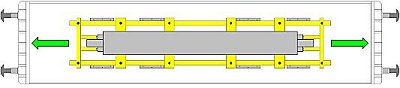

| The sliding loading method - Plan view |

The loads must be secured against sideways movement. Squared wooden guide rails attached next to the loaded goods or sleds in such a way that the load not prevented from sliding have proved themselves in practice.

Any movement by the load must not cause permitted axle loads to be exceeded. Thus, the maximum permissible load of the freight car cannot be fully exploited. The axle load must not exceed the value that results when the sum of the tare weight plus the permitted maximum load is divided by the number of axles or bogies. The ratio of the axle loads of cars with two axles must not exceed 2:1, that of bogie cars must not exceed 3:1.

If the floor surface is of the same nature, goods will slide the same distance, regardless of their mass. Thus a number of partial loads or load groups consolidated as blocks can be loaded on a car using the sliding loading method. The loading guidelines require a gap of 50 cm between the individual goods/groups. When using this type of loading, several consecutive jolts during switching should not occur in the same direction. Cars loaded in this manner are specially checked at the switching yards.

|

|

The term rigid loading comes from the loading guidelines published by the UIC (International Rail Union) and is used as a blanket term to cover both compact loading and individual securing.

The term "rigid loading" means exactly what it says: the load must be secured on or in a cargo transport unit in such a way that it is unable to move. If this demand is met, the load is unable to topple, fall down or become damaged/cause damage in any way. However, the term does not specify the method of securing that is to be used.

The term "compact loading" also clearly indicates the concept. A compact load is one which is stowed without gaps or, insofar as gaps remain, where these gaps have been filled by resilient material.

The term also immediately suggests that the CTUs must have borders of sufficient load bearing capacity around the loading area in order to allow a compact unit to be formed in which nothing is able to move. Even this simple description makes it clear that a CTU that does not have fixed side or end walls is not suitable/only partially suitable for securing loads in this way.

Individually secured loads are attached to the transport unit using special load securing aids. The term does not, however, indicate exactly how securing is to take place. It does however, imply that certain components must be available or certain requirements must be in met in order to allow loads to be secured individually: These components may be lashing points or other securing mechanisms on either the transport unit itself or the load.

If these load securing measures are carried out correctly, both of the important requirements of load securing will have been met: The load is unable to slide or tip. If we go into more detail, tipping can fall into two categories.

|

There's still time to ask for information. |