|

|

| Do not work in a too confined a space! |

The area in which containers are packed should be spacious enough to prevent staff from obstructing each other. If too many cargo items are made available in a tight space and several fork-lift trucks are used, this can easily lead to a reduction in efficiency and damage to the goods.

|

Use lift trucks with lighting! |

Quick changes from brightness to darkness are extremely demanding for fork-lift truck drivers' eyes. They can cause damage by bumping etc. before their eyes have adjusted to the darkness. Recommendation: Use lift trucks with adequate lighting!

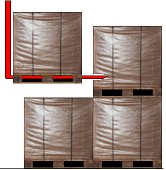

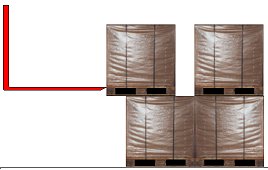

| When loading under tight space conditions, there is a risk of damage. In the case of bagged cargo, "bleeding" paper bags can endanger the stability of the entire block. To minimize the risk of damage, a helper should hold a sufficiently wide strip of hardboard vertically between the cargoes when the pallet is inserted. |  |

|

| Risk for bagged cargo pallets | ||

|

Work on homogeneous cargo items should be carried out using attachments suited to the goods in question. With heterogeneous loads, attachments should only be used if the devices can be attached and detached very quickly. The drum clamp shown above is picked up and put down by inserting or removing the fork. It is quickly secured by two pins and released again by removing the pins. It is always more efficient to work with fork-lift trucks equipped with a fork adjustment device and whose forks can be moved laterally in parallel.

|

|

|

| High-risk working methods | ||

Packages are often mechanically ruptured by forks on loading and unloading as a result of carelessness, inexperience etc. If the forks are used to push a package into place, the forks can slip down and cause damage. This risk is particularly high if the equipment is in poor condition and the tips of the forks are not exactly parallel horizontally. If the forks are too long, goods stowed further behind are often also affected. Should damage of this kind remain unnoticed, it can pose risks to the environment and in the case of dangerous cargoes, cause substantial consequential losses and signify a violation of the law. As Section 4.2.7 of the CTU guidelines says:

- Packages of dangerous cargoes should be examined and any found to be damaged, leaking or sifting should not be packed into a CTU.

|

|

Damage caused during stacking or when pushing a load into place can effectively be prevented by using pieces of squared lumber of a suitable length and format, laid on and/or fastened to the rear of the forks.

|

High-risk working method |

Packages should always be picked up resting fully on the fork and set down level. Loads should not be pushed with slightly raised fork tips. This could otherwise cause damage to the bottom of certain loads.

|

Faulty packaging |

When handling long goods, the forks should be set as wide apart as possible from each other. Here, however, the packaging is the main concern. If long goods have to be pushed into containers, skids running in a longitudinal direction must be provided. Strapping must not run along the belt battens at the bottom. They must run along a milled groove.

|

|

||

| Belt battens without a groove | Belt batten with a groove |

If overstowage of the cargo items is an issue, the steel strapping should run in a groove at the top in the same way. An all-round groove is ideal. To prevent the strapping from tearing off, suitable hardboard strips can be placed under the belt battens with the smooth side facing down. This reduces friction, which in turn makes it easier to push loads in.

|

|

| Correct arrangement of skids |

Cases built like this are easy to push into containers provided they have been set down with the front end in the door area. This has not been done here. Loads should not be pushed over a ramp, since usually the metal sheets are textured or made of deck plate.

|

|

| Inadequately packaged goods |

Even the best packing company in the world cannot reasonably be expected to work well if the goods they are delivered are atrociously packed. Here, the load unit was destroyed by a braking maneuver of the fork-lift truck. Generally, only professionally prepared units should be loaded. Matters may be improved in the long term by inspection of incoming goods, good customer contact and regular quality control at the consignor end.

|

|

|

| Inadmissible pushing | ||

Pushing gently with a pallet as padding can be tolerated for certain goods in exceptional cases. It cannot be tolerated with goods which could be damaged by such actions.

There is a considerable risk of damage on unloading at the destination, if the packers do not have the stripping of the container in mind when loading it. Cargo must always be packed in such a way that the cargo transport units can be unloaded as easily as possible. This can also mean attaching belts, slings or similar to individual cargo items which can then be used to pull out the items. If, for instance, it would be difficult for recipients to attach slinging equipment to loads in open-top containers, the shipper should leave it in place and tie it together in such a way that it is immediately accessible from the top.

When working with lifting gear and single hoisting points, auxiliary ropes should be attached to the load or the hoisting equipment to be able to safely guide the cargo items.