Whether a material is to be classed as dunnage, segregation or load securing material does not depend on the material itself but on its application.

The main functions of dunnage are:

- Protection against sweat and condensation water

- Protection against moisture and liquids

- Protection against soiling and contamination

- Protection against mechanical damage

To ensure protection against moisture and liquids, cargoes which are at risk and sensitive parts of the means of transport must be shielded. A check must be made for any possible leakage in the means of transport or other cargo items. Potential causes of this could be leaky walls, doors and roofs on the cargo transport units, or damaged drums, cans and other similar packaging receptacles for "wet cargoes". The effects of wet or very moist load securing materials must also be taken into account.

Protection against soiling and contamination must be ensured. This can be caused by the presence of contaminating goods or contaminated components on the cargo transport units. Contaminating goods must also be enclosed by dunnage to prevent them from damaging other goods or parts of the means of transport.

Preventive measures are always needed to protect against mechanical damage, if contact with components on the cargo transport unit itself or other loads or load items could cause mechanical damage. For instance, it can be necessary to adequately protect the load against contact with corrugations, corner posts, doors, lashing points, stanchions, edges and corners of other cargo items, load securing materials, protruding nails, screws etc. Appropriate dunnage must also be used to reduce the effects of harmful pressure forces.

The nature of the materials used must ensure that the packages or the cargo transport unit are adequately protected. The materials themselves must not be wet, moist, odor-tainted or contaminated. The quality of the material must determined for each individual case by assessing the value and susceptibility to damage of the load, the means of transport, the intended protection and other similar factors. The special properties of the particular type of dunnage used must be taken into account.

Wooden dunnage made of squared lumber, planks, boards, slats and battens, are very suitable for distributing pressure, bridging or lining cavities and gaps, creating air channels and enhancing friction. If wooden dunnage is laid too tightly, it impedes air circulation (this is a particular consideration for ventilated containers), causes a significant loss of stowage space and thus increases costs. Large spaces promote air circulation but can cause mechanical damage to the packages if the load-bearing area is too small. Wood easily absorbs moisture and releases it into the environment at a low vapor pressure. If it has a strong intrinsic odor or has taken up a foreign odor, it must not be used with odor-sensitive loads. Since wood can be infested by pests, only wood which has been impregnated against insects or fumigated may be used on certain trade routes. To distinguish such treated wood from normal wood, it must be appropriately stained or marked in some other way.

Wooden boards, wooden panels, walking boards, chipboard and hardboards are very suitable for distributing pressure and have a high loading capacity provided they are sufficiently thick. Since water-repellent, pest-proof or fire-retarding wood is odor-tainted as a result of such treatment or could have other harmful effects, it must virtually never be used with foodstuffs or similar items.

Mats made of rattan, bamboo, reed etc. only protect against surface dirt, not against dust. They absorb moisture and under certain circumstances release it back into the atmosphere. This can protect adjacent loads. Mats are easy to put in place and roll back up again, and do not cause any significant loss of stowage space. Provided a container is actively ventilated, mats can release back into the atmosphere any sweat or drops of water they have absorbed.

Canvas has a water-repellent impregnation and therefore not suitable for odor-sensitive goods. They are dust-tight. They impede air circulation.

Tarpaulins are watertight, dust-tight and airtight and very expensive. They must be handled with care if a long life is to be expected. It is very rare that tarpaulins will not be needed as a cover to protect against moisture and similar influences.

Jute coverings protect against surface dirt but not dust. They are breathable and allow a minimal amount of ventilation. They pass on absorbed moisture to the wrapped or surrounding cargo items. When used with fatty organic goods, jute coverings can spontaneously ignite or promote the spontaneous combustion of other goods.

Sailcloth has similar properties to canvas.

Plastic sheeting is available in a number of different thicknesses. It is neutral in odor, inexpensive and generally acid-proof and alkali-proof. It is watertight, dust-tight and airtight but only impervious to water vapor to a limited degree. It has a low loading capacity if it is not sufficiently thick. Composite sheeting is often very heavy-duty but comparatively expensive.

Paper, e.g. normal kraft paper, is inexpensive and dust-tight, but very sensitive to moisture. Fabric paper has a higher strength. Oiled paper is watertight. Tissue paper is acid-free.

Dispersible material such as talcum powder and similar materials can be used to prevent cargoes from caking together.

Depending on their use and application, a distinction is made between:

- Floor dunnage

- Interlayer dunnage

- Top dunnage

- Side dunnage

Floor dunnage is used for the following tasks:

- Dissipating and localizing sweat and moisture

- Protecting the load from moisture and dampness on moist or wet stowage surfaces or stowage spaces

- Dissipating or restraining moisture leaking out of the load, to protect other packages or the cargo transport unit

- Protecting the load from soiling, contamination or mechanical damage from the stowage surface or stowage spaces

- Protecting the cargo transport unit against negative influences from the goods

There are no generally binding regulations for laying dunnage. The condition, properties and intended protective action of the available materials and similar considerations must be taken into account. In many cases, only compromises can be considered, since some fundamental requirements can contradict each other; especially if materials are to assume a number of protective functions simultaneously.

The following guidelines are intended to help make practical decisions. Since not all variants can be shown, the action and decisions taken will need to reflect the given circumstances. How to lay dunnage most appropriately and what materials are to be used depends on the stowage space, the structural design of the cargo transport unit and the restrictions anticipated during transport. These include the climatic zones through which the cargo will travel, changes in weather, storage duration and voyage duration, anticipated mechanical, climatic and biotic shipping stresses etc.

Wooden dunnage is differentiated according to the quantity and thickness of the wood used and the method used to lay it:

- Simple wooden dunnage comprises boards laid out side by side.

- Double dunnage or criss-cross dunnage comprises boards laid at right angles to or obliquely over each other.

- Raised dunnage can comprise planks or squared lumber laid in single layers or a combination of boards, planks or beams laid at right angles to or obliquely over each other. Another good option is to use pallets as stowage surfaces.

The orientation of and space between the wood used depend on the intended protective effect and the nature of the means of transport or the stowage space:

If the main aim is to dissipate moisture or damp, the wood at the bottom must be laid in such a way that water and other fluids are conducted along the quickest route outside or to any available discharge outlets and do not produce any accumulation of damp. It is not practicable to dissipate liquid to the outside in standard containers which have not been structurally modified, since these containers are spray-tight and thus generally prevent water from flowing out freely. If actively or passively ventilated containers can be used, criss-cross dunnage can enhance the ventilation effect. When laying out dunnage, it should be remembered that ships are not constantly on an even keel. They can be trimmed by the stern or trimmed by the bow. Rolling and pitching cause the deck to slope. These slopes, as well as any special factors in the ship's construction, must be taken into consideration when laying out wooden dunnage. With open containers, dunnage can be laid out transversely. Liquids can immediately flow out when the ship rolls. If the ends of the wooden boards are taken right up to the side rails, load forces are distributed appropriately at the same time. It should be remembered that closed containers are spray-tight and that dissipation of moisture to the outside only happens to a limited degree and then only slowly.

If a good distribution of load forces is the primary consideration, the wood at the bottom must be laid out in such a way that as many load-bearing components of the cargo transport unit are covered as possible.

If good moisture dissipation is as important a consideration as a good distribution of load forces, the best possible compromise must be reached, for instance by laying out the base wood diagonally.

If the most important consideration is to protect against mechanical damage, it is essential that potential shifting or movement resulting from shipping stresses and typical for the particular means of transport are taken into account.

If goods which are sensitive to dirt, moisture or mechanical damage are loaded, additional materials such as mats, jute cloth, paper, sheeting etc. are to be used as required.

If there is a danger of dampness or contamination of the packaging spreading to the contents, dunnage must be laid with special care.

If plastic sheeting and similar materials are used to prevent dampness from penetrating the cargo, their orientation the way they are arranged play an important role. In these cases, consideration must be given to where damp could enter and where it can be dissipated. Under no circumstances must "water pockets" be allowed to form, which would enable collected damp to enter the cargo. Dunnage must first be laid out at the point where most water is able to penetrate.

|

|

|

| Interlayer dunnage | Floor dunnage |

Laying out floor dunnage to protect from damp in containers will always be necessary when "wet goods" are stowed together with moisture-sensitive goods. Occasionally, criss-cross dunnage and double dunnage will be necessary. Damp must be prevented from infiltrating sensitive cargoes by laying dunnage at appropriate heights and using additional material, e.g. plastic sheeting. In box containers, it is generally more appropriate to lay out wooden dunnage in a longitudinal direction, because of the distribution of load forces and the use of ground conveyors. On open containers, it should be laid out transversely. In both cases, the load-bearing components must be bridged for heavy packages so that the permissible line load is not exceeded.

On open chassis and trailers, wood must be laid out to distribute load forces in such a way that the load is taken by the vehicle's chassis. Walking boards made of glued-laminated plywood at a size of 1 m x 2.5 m, for instance, or wooden boards of a suitable length and adequate dimensions are very suitable for this. Floor dunnage made of wood or plastic sheeting is used to prevent contamination. Since it is possible that cargo transport units can be transported on deck, sufficient protection against damp must be ensured. When distributing load forces, the vehicle chassis and cross members must be covered.

Floor dunnage is very often not needed for freight cars with a wooden floor. If there is a risk of damp infiltration with moisture-sensitive cargoes, appropriate measures must be taken. On covered freight cars, the preferred orientation of the wood is longitudinal, in the door area it is transverse. On open freight cars and freight cars with sliding walls, wood is preferably to be laid out transversely for loading and unloading with ground conveyors. Exceptions to this must be made when end-loading platforms are used. The design of the chassis and of the side rails and cross members must be taken into account with regard to the distribution of load forces. Here, inexpensive materials such as paper, plastic sheeting etc. are sufficient for protection against contamination.

What has been said about freight cars applies in principle to cargo transport units for road transport. On box bodies, however, wood should always be laid longitudinally where possible, for handling reasons.

To be able to effectively protect cargo before packing and after unpacking cargo transport units, dunnage can also be required in stores, sheds, warehouses, hangars and open areas. This can be for leveling out storage areas, protecting against damp and dirt or for distributing load forces. The orientation should be suited to the transport paths and the equipment used. The materials used must be able to provide the necessary protection. Especially on open areas, weather changes such as rain, snow, ice etc. must be taken into full account. Other factors to consider are bacteria on the ground and rot pathogens which could damage the cargo.

Side dunnage has similar functions to floor dunnage:

- Protection against damp or moisture penetrating from the side as a result of sweat or leakage from other cargo, but also protection of other cargo or of the means of transport against liquids escaping from the side of a load.

- Protection against soiling and contamination on the sides, both of a single load against other loads or from parts of the means of transport, or protecting the latter against a specific load.

- Protection against mechanical damage or other damage, such as chafing, tearing, chemical reactions etc. both with regard to a specific cargo and to other cargoes or parts of the means of transport.

The same materials are used for lateral dunnage as for floor dunnage. The use of wooden dunnage, however, is less significant.

To protect against damp or moisture or harmful dust penetrating from the sides, watertight and dust-tight materials such as plastic sheeting, oiled paper and tarpaulins are to be used. Under certain conditions, canvas and mats should also be used, but never wrappers or paper.

Sweat formation always occurs when temperature differences are too high, either with a positive temperature difference against the load or a negative temperature difference against components of the means of transport. For further information on this, see section 10.3.4 "Sources of sweat". The risk of sweat is higher on cargoes with a high water content. If there is a risk of cargo sweat (section 10.3.6.4) and the cargo is sensitive to moisture, it is urgent that a corrosion protection method is used (see http://www.tis-gdv.de/tis_e/verpack/inhalt1.htm). Wrapping cargo in plastic sheeting can have the opposite effect to that which is desired. Since hot air rises, water vapor can condense under the sheeting.

Practical experience shows that wooden dunnage boards, wooden boards, mats etc. provide good protection against mechanical damage. Whether or not it is necessary to use additional materials depends on the particular circumstances.

Top dunnage is laid to prevent the consequences of leakage, sweat formation, bad weather, vertical shipping loads etc., which could damage a particular cargo or the cargo transport unit and its components.

The main functions of top dunnage are:

- Protection against damp or moisture penetrating from the top or escaping upward

- Protection against dust or substances which threaten contamination or chemical reactions, either penetrating from the top or escaping upward

- Protection against mechanical damage anticipated to arise from above or acting in an upward direction

All previously described materials can be used as top dunnage materials.

To protect against damp or moisture penetrating from the top, or to prevent moisture from being allowed to permeate upward, plastic sheeting, oiled paper, tarpaulins and other watertight materials have proved themselves in practice.

If only small quantities of moisture are anticipated, the best materials to use are ones which can absorb small quantities of water.

The type of nonwoven fabric shown can absorb relatively large quantities of dripping water. Since the weight increases when these properties are used, it must be attached carefully.

|

Special absorbent, nonwoven fabric cover as top dunnage |

When using watertight materials, it is essential that liquid which has collected in depressions (water pockets) is prevented from flowing into the cargo when the vehicle moves. For this reason, plastic sheets etc. must overlap each other properly or wood, cargo items or the stowage method must be used to create an appropriate slope. Respiring organic goods, such as tobacco, coffee, cocoa, fish meal etc., which are transported in passively ventilated containers, must not be covered with airtight materials or materials impervious to water vapor.

If top dunnage is used to protect against contamination or to prevent harmful chemical reactions, the same principles apply as for protecting against damp, but the materials must be dust-tight and chemically compatible. A certain degree of air circulation must also be ensured here occasionally.

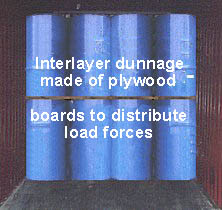

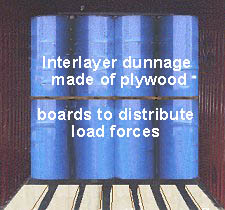

Interlayer dunnage variously has the functions of floor dunnage, side dunnage or top dunnage, depending on how it is arranged. It is laid between two different batches or individual goods in a batch or load type.

|

Interlayer dunnage on a load of pails |

In some cases, it simultaneously helps secure the load by increasing friction, improving the distribution of load forces or improving the stability of the load.

All materials which have been described can be used. In addition, powdery substances such as talcum powder. They are introduced in the form of an intermediate layer or are sprinkled between layers, to prevent loads from sticking together, e.g. with bales of raw rubber.

Interlayer dunnage comprised of mats provides adequate firmness and protects against mechanical damage.

Here, wooden dunnage boards were used to create a level packing surface. But will the bottom left carton of the load be able to bear the load packed on top of it? This ought to be supported from beneath using vertical squared lumber.

|

Interlayer dunnage made of wooden dunnage used as a leveling aid |

|

Inadequate interlayer dunnage of wooden dunnage boards |

Further measures should to be taken here as well. As in so many cases, inadequate unitization is responsible for additional work - which sadly is not very productive in this case.

|

Left and bottom: Missing interlayer dunnage |

|

|

| In both examples, the use of interlayer dunnage is urgently recommended. |