For securing individual items, a tight fit may be achieved using bracing, especially in corrugated steel containers. On the other hand, the possibilities for lashing are very limited. Relatively useful lashing lugs or rings are provided in all inland containers. Problems arise if lashing points are overstowed and are no longer available or reachable. Their strength also presents a problem: in general, their Maximum Securing Load (MSL) or Lashing Capacity (LC) is only 1,000 daN per lashing point.

|

Lashing points on the frame parts of a container |

The lashing points for containers are not currently covered by standards and may therefore differ greatly. Not all lashing points may be loaded in all directions.

|

|

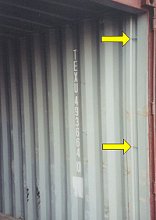

Lashing bars on the corner posts in the door area |

Lashing points must be attached to the frame parts of a container, since only these components are adequately capable of absorbing forces.

|

"Lugs" in the area of the top side rails/ top side rails |

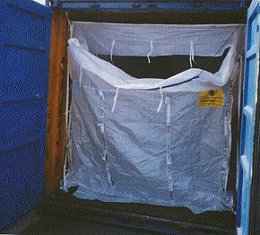

Lugs fitted in the area of the top side rails and sometimes also the front top end rails can only be used to a minimal degree for traditional cargo securing by lashing. Lugs are suitable, indeed almost too strong, for attaching "inlets" or special nonwoven fabric for catching sweat.

| Nonwoven fabric providing protection against condensation water |  |

|

|

| Attaching nonwoven fabric |

|

In any case, such measures serve to protect the cargo, and therefore to keep it safe: nonwoven fabrics provide protection against moisture or wetness dripping from the container ceiling and "inlets" protect against contact with the container walls. Some containers have lashing bars halfway up the container walls. In corrugated steel containers, they are welded in between the corrugations. The maximum securing load of these bars is not very high and they can only be used to secure relatively light individual items or small blocks of palletized cargo. The same applies to individual lashing rails fitted into the wooden linings of aluminum containers.

Platform containers, i.e. the group comprising platforms and flatracks, have a relatively large number of reasonably strong securing elements.

|

Stanchion pocket in a 40' collapsible flatrack |

To achieve a tight fit by application of pressure, stanchions or stakes are very often provided, which may be inserted into corresponding stanchion (or stake) pockets.

|

Right and left: Do not attach lashings to stanchion (or stake) pocket components |

|

Although the stanchion (or stake) pocket closing bar looks suitable for use as a lashing bar, this is expressly forbidden.

|

|

|

Lashing points next to stanchion pockets on flatracks |

|

Flatrack with lashing rings |

|

|

|

|

Lashing point on the bottom rail of a flatrack |

|

Safe Working Load |

|

Maximum Pull Strength |

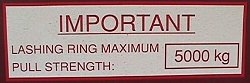

It is regrettably often the case that no details are given about the strength of lashing points. Even if information is provided, it is mostly of no practical use because of the wording chosen. Further explanations relating to this problem are provided in the section headed Lashing materials, which states:

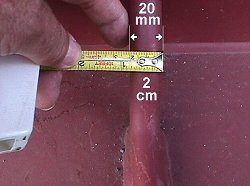

The maximum securing load (MSL) can be calculated using a rule of thumb, according to which the diameter of the lashing points is determined, squared and multiplied by 10; i.e. diameter x diameter x 10. The result of the calculation is in decanewtons (daN) if the diameter is stated in millimeters and kilonewtons (kN) if the diameter is stated in centimeters.

|

Determining the maximum securing load of lashing points using rule of thumb method |

According to the above-stated rule of thumb, the maximum securing load of the lashing point is determined as follows:

| In decanewtons: | 20 | · | 20 | · | 10 | = | 4,000 | daN |

| In kilonewtons: | 2 | · | 2 | · | 10 | = | 40 | kN |

|

The rule cannot be applied, either, if the lashing points, e.g. rings, are held on with pop rivets, thin screws or the like, despite the rings "looking good". |

Some platform containers have special securing systems:

| Integral belt system in a 40' flatrack - one side ... |

|

... and the other side |

This flatrack has fixed belt reels, all on one side. The eyelets of the textile belts can be secured on hooks on the other side. Unfortunately, this securing system is virtually unusable, because the "tie-down lashing/over-top lashing/friction loop" method has only a frictional effect, and this only with one-sided, uneven pretension. The belts do not allow a homogeneous tight fit to be achieved. If four of the total of eight lashing reels were fitted on each side, appropriate securing could be achieved for many types of goods.

The containers themselves are secured on ships and road and rail vehicles by means of the container corner castings. Appropriate securing systems, such as rods on board ship, twist locks or other lock units etc., may be attached in or to the corner castings, which are also responsible for load transfer if the containers are stacked in ship cell guides.

|

|

| Securing of a container to a chassis | |

Occasionally, complaints arise during road-side cargo securing inspections because not all of the lock units have been firmly tightened, when of course they should be. The CTU packing guidelines provide advice on this matter. Section 6.4 states, on the subject of "CTUs on vehicles":

- 6.4.1 CTUs should be firmly secured on vehicles before the vehicle is moved. The most appropriate points for fixing containers and swap-bodies are the bottom corner castings of the unit. Before and during transport, it should be checked that the unit is properly secured on the vehicle.

- 6.4.2 For transport on public roads or by rail, containers and swap-bodies should be secured to the road or rail vehicle by all bottom corner castings, in the absence of which, appropriate alternative measures should be taken. The main forces during the transport operation should be transferred to the unit through these bottom corner castings. Some additional forces may be transferred between the road vehicle chassis or rail-car surface and the unit bottom through load transfer areas in the unit bottom and in the vehicle surface. The securing devices on the vehicle may be twist locks, securing cones or securing guides. All such securing devices should be designed in such a way that the "open" or "locked" position of such securing devices is readily apparent.

It is very common for problems to arise when containers, loaded in particular on road vehicles and attached firmly thereto, have to be carried by combined road/ship/road transport. Only occasionally do the vehicles have the legally prescribed lashing points, and even if they are present, they tend to be positioned extremely unfavorably or to be incorrectly or defectively designed. As at 2003, this is true of approx. 80% of all vehicles which have to be carried by sea.

On this matter, Point 2.1.6 of the CTU packing guidelines states:

- A vehicle should be provided with points for securing it aboard ships (refer to European Standard EN 29367-I (ISO 9367-1): Lashing and securing arrangements on road vehicles for sea transportation on Ro/Ro ships - General requirements - Part 1: Commercial vehicles and combinations of vehicles, semitrailers excluded, and to EN 29367-2 (ISO 9367-2): Lashing and securing arrangements on road vehicles for sea transportation on Ro/Ro ships - General requirements - Part 2: Semitrailers".)

|

|

||

| Strong, well-positioned lashing point on a semitrailer | Will the screws withstand the stresses of maritime transport? |

|

|

| Unfavorably located lashing point - unusable |