An undamaged, tightly closed box container protects its contents from external influences such as ice, snow, rain, salt spray, dust, thermal radiation, ultraviolet light and other conceivable environmental influences.

|

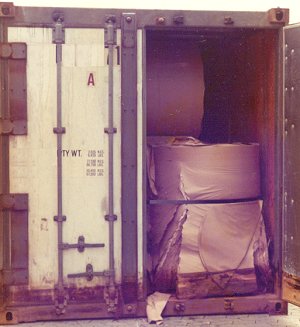

Water damage in a container |

However, box containers cannot provide protection from direct exposure to water because they are only spray-tight, not water-tight.

The CTU packing guidelines state that moisture damage must be avoided, point 3.2.7 reading:

-

In order to avoid cargo damage from moisture, wet cargoes, moisture-inherent cargoes or cargoes liable to leak should not be packed with cargoes susceptible to damage by moisture. Wet dunnage, pallets or packaging should not be used. In certain cases, damage to equipment and cargo can be prevented by the use of protective material such as plastic films.

|

|

| Rain-wettened cartons on wet pallets - moreover inadequately palletized |

If containers are packed in the open, there is always a risk in rainy weather that ground conveyors and personnel will bring moisture into the container with them.

Cargoes in a container in which air exchange is prevented may suffer spoilage or be damaged if temperatures and humidities during carriage reach a level which is incompatible with the goods or their packaging containers.

Point 1.3 of the CTU packing guidelines points out the negative effects of changes in temperature and humidity on container cargoes:

-

During longer voyages, climatic conditions (temperature, humidity etc.) are likely to vary considerably. These may affect the internal conditions in a CTU which may give rise to condensation (sweating) on cargo or internal surfaces.1 Where cargo is liable to damage from condensation, expert advice should be sought.1 (see Annex 1)

|

Ice formation on a ship |

If relatively warm air is cooled to below its dew point, the resultant condensation may result in cargo damage.

|

|

| Wetting damage on bags of raw cocoa due to condensation |

Additional information is provided in the stated Annex 1 "Condensation".

-

1. Cargoes in transit may be affected by the conditions to which they are subjected. These conditions may include changes in temperature and humidity and particularly cyclic changes that may be encountered). An understanding of condensation phenomena is desirable because condensation may lead to such damage as rust, discoloration, dislodging of labels, collapse of fiberboard packages or mold formation.

- 2. Solar radiation can produce air temperatures under the inner surfaces of a CTU which are significantly higher than external air temperatures. The combination of these effects can result in a range of day and night cyclic temperature variations in the air adjacent to the inner surfaces of a CTU which is greater than the corresponding range of temperatures just outside.

- 3. Cargoes closest to the wall or roof will be more affected by external temperature variations than those in the center of a CTU. If the possible extent of temperature variations or their full significance is not known, advice should be obtained from specialists.

- 4. Under the circumstances described, condensation may occur either on the surface of the cargo (cargo sweat) or on the inside surfaces of a CTU (container sweat) either during transport or when the unit is opened for discharge.

- 5. The main factors leading to condensation inside a CTU are:

| 5.1 | sources of moisture inside the unit which, depending upon ambient temperature conditions, will affect the moisture content of the atmosphere of the unit; |

| 5.2 | a difference between the temperature of the atmosphere within the unit and the surface temperature of either the cargo or the inner surfaces of the unit itself; and |

| 5.3 | changes in the temperature of the outer surface of the unit which affect the two factors above. |

- 6. Warming the air in a CTU causes it to absorb moisture from packagings or any other source. Cooling the air below its dew point* causes condensation.

-

7. If, after high humidity has been established inside a CTU, the outside of the unit is cooled, then the temperature of the unit surface may fall below the dew point of the air inside it. Under these circumstances moisture will form on the inner surfaces of the unit. After forming under the roof, the moisture may drop onto the cargo. Cyclical repetition of cargo or container sweat phenomena can result in a greater degree of damage.

-

8. Condensation can also occur immediately after a CTU is opened if the air inside the unit is humid and the outside air is relatively cool. Such conditions can produce a fog and even precipitation but, because this phenomenon usually occurs only once, it seldom results in serious damage.

-

9. The risk of damage and dangerous situations** can be minimized if the moisture content of the packaging and securing materials is kept low.

*The dew point is the temperature at which air saturated with moisture at the prevailing atmospheric pressure will start to shed moisture by condensation.

** For example, when goods of class 4.3 (substances which evolve flammable gases on contact with water) are packed into a container.

Where necessary, the information provided in Annex 1 "Condensation" may have to be supplemented by additional information from other sources.