-

Rail transport, in addition to subjecting cargo to vibrations (16 Hz), may also lead to shocks as a result of shunting [switching] operations. Many railways have organized their operations in such a way as to avoid shunting [switching] of railway wagons [rail cars] incurring high forces (e.g. by operating dedicated block trains) or by moving CTUs on wagons [cars] with high performance shock absorbers that are normally able to reduce shunting [switching] shock forces. It may be advisable to ensure that such operational features have been established for the rail journey.

-

Shunting [switching] means the operation when single railway wagons [cars] or groups of railway wagons [cars] are pushed to run against each other and be coupled together.

|

|

| Switching engine with dangerous cargo container on a special rail car |

Operationally, switching includes quite wide-ranging activities which will not be addressed in greater detail here. In modern switching yards, trains are divided up and reassembled by being pushed (for example with a switching engine) up and over a hump yard, so automating hump switching operations. The speed of the rail cars as they run down the hump is kept within the desired range by special braking or driving systems. Major switching impacts are a thing of the past. In a conventional system, the rail cars running down the hump are brought to a standstill with drag shoes. If the worker laying the drag shoes makes a mistake, switching impacts involving considerable deceleration may occur. If no hump yard is available, groups of rail cars are "kicked" by switching engines and the individual cars run into the appropriate sorting sidings, where they are again conventionally brought to a standstill with drag shoes. In this case too, high deceleration values may occur when the cars collide. Lower levels of deceleration occur when the cars are pushed to activate the couplings. The UIC specifies an acceleration value of 4 g for normal switching operations. Containers are not constructed for such stresses and should not be exposed to such acceleration forces.

Rail cars with high-performance buffers, as mentioned by the CTU packing guidelines, cut the "normal" switching impacts of 4 g in half to 2 g. In Germany, these rail cars with high-performance buffers have a lower case j in their name, for example Lgjs, Sgjs, Sgjkkms etc.

|

Rail car with high-performance shock absorbers |

|

|

| Rail cars with high-performance buffers |

According to railroad operating procedures, a whole range of different rail cars must not be switched normally. This is determined by the type of rail vehicle, the type of loading or certain features.

|

Reasons for operating under caution ticket scheme |

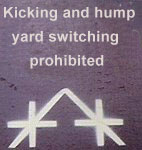

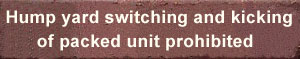

Rail cars operated under this scheme are either specially marked "from the outset", e.g. "Hump yard switching and kicking prohibited", "Switch carefully" etc., or they may be provided with special tickets bearing a yellow triangle standing on its apex, a red circle ticket or the standard caution tickets. Rail cars operating under the caution ticket scheme are divided into three classes.

|

|

|

Caution ticket marking, class 1 |

|

|

|

|

|

|

| Caution ticket marking, classes 1, 2 and 3 | ||

The CTU packing guidelines also define block trains as follows:

-

Block train means a number of permanently coupled railway wagons [rail cars], normally running directly between two selected terminals or entities without shunting [switching].

| Mode of transport: rail | Forward acting forces |

Backward acting forces |

Sideways acting forces |

| Rail cars subject to shunting [switching]* | 4.0 g | 4.0 g | 0.5 g (a) |

| Combined transport** | 1.0 g | 1.0 g | 0.5 g (a) |

| 1 g = 9.81 m/s² | |||

| The above values should be combined with static gravity force of 1.0 g acting downwards and a dynamic variation of: (a) = ± 0.3 g. | |||

| * The use of specifically equipped rolling stock is advisable (e.g. high-performance shock absorbers, instructions for shunting [switching] restrictions). | |||

| **"Combined transport" means "wagons [cars] with containers, swap-bodies, semitrailers and trucks, and also block trains (UIC and RIV)". | |||

Table from the CTU packing guidelines

In relation to the Table, it is stated in point 1.7 of the CTU packing guidelines that examples of accelerations are given which could arise during transport operations:

-

... However, national legislation or recommendations may require the use of other values.

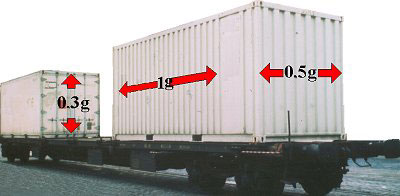

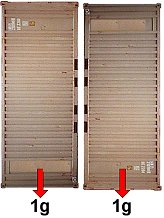

The same values are also specified by the VDI guidelines for intermodal transport. In road-rail intermodal transport, the following values are thus obtained: 1 g in the longitudinal direction, 0.5 g sideways and 0.3 g vertically.

|

|

| Acceleration values in intermodal transport |

From the standpoint of the cargo, a longitudinal acceleration of 1 g is the same as if the container had been stood up vertically, first in one direction and then the other.

|

|

|

| Longitudinal acceleration in intermodal transport is the same as if the CTU had been placed vertically. |

Sideways acceleration of 0.5 g corresponds to a tilt angle of 30°. |

Sideways acceleration values in road-rail intermodal transport are identical for both modes of transport. They correspond to a tilt of 30°.

|

|

| Effect of vertical acceleration of ± 0.3 g in rail transport |

The effects of acceleration of ± 0.3 g are similar to each package in the container alternately becoming 30% heavier and then 30% lighter than its true weight.

Note:In the case of carriage by railroad companies in other continents or countries such as Africa, China, India, Canada, Russia, USA etc., information should be obtained about the prevailing conditions in each case. In some cases, stresses may be higher than in Europe. For example, in winter many containers destined for receivers close to the Great Lakes are unloaded in Halifax and carried by rail, for example to Detroit, because the sea route via the St. Lawrence Seaway is impassable due to ice.