-

Voyages are made in a variety of weather conditions which are likely to exert a combination of forces upon the ship and its cargo over a prolonged period. Such forces may arise from pitching, rolling, heaving, surging, yawing or swaying or a combination of any two or more.

-

Packing and securing of cargo into/onto a CTU should be carried out with this in mind. It should never be assumed that the weather will be calm and the sea smooth or that securing methods used for land transport will always be adequate at sea.

|

Ship movement at sea |

All kinds of ship movement may be divided into three types of linear motion and three types of rotational motion.

|

| Linear motion | Rotational motion |

| Surging is motion along the longitudinal axis. | Rolling is motion around the longitudinal axis. |

| Swaying is motion along the transverse axis. | Pitching is motion around the transverse axis. |

| Heaving is motion along the vertical axis. | Yawing is motion around the vertical axis. |

Summary of ship movement

It can in general be stated that the outwardly directed centrifugal accelerations brought about by any rotational motion are not significant. This accordingly applies to yawing, pitching and rolling.

|

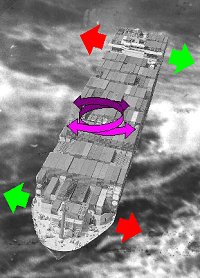

Yawing is motion around the ship's vertical axis. |

Yawing involves rotation of the ship around its vertical axis. This occurs due to the impossibility of steering a ship on an absolutely straight course. Depending upon sea conditions and rudder deflection, the ship will swing around its projected course. Yawing is not a cause of shipping damage.

|

|

|

|

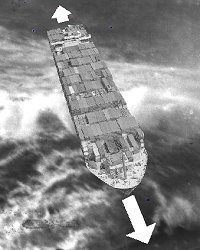

| Heaving is motion along the ship's vertical axis. |

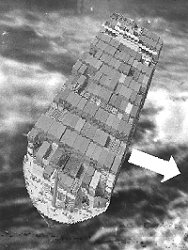

Heaving involves upward and downward acceleration of ships along their vertical axis. Only in an absolute calm are upward and downward motion at equilibrium and the ship floats at rest. Buoyancy varies as a ship travels through wave crests and troughs. If the wave troughs predominate, buoyancy falls and the ship "sinks" (top picture), while if the wave crests predominate, the ship "rises" (bottom picture). Such constant oscillation has a marked effect on the containers and their contents.

|

|

|

| Surging is motion along the ship's longitudinal axis. |

Swaying is motion along the ship's transverse axis. |

In surging and swaying, the sea's motion accelerates and decelerates the ship forward and backward and side to side. Depending upon the lie of the vessel, these movements may occur in all possible axes, not merely, for example, horizontally. If a vessel's forebody is on one side of a wave crest and the afterbody on the other side, the hull may be subjected to considerable torsion forces.

|

|

| Pitching is the movement of a ship around its transverse axis. |

In pitching a ship is lifted at the bow and lowered at the stern and vice versa. Pitching angles vary with the length of vessel. In relatively short vessels they are 5° - 8° and sometimes more, while in very long vessels they are usually less than 5°. In a container ship 300 m in length with a pitching angle of 3°, a container stowed in the bay closest to the bow or stern at a distance of approx. 140 m from the pitching axis will cover a distance of 29 m within a pitching cycle, being raised 7.33 m upwards from the horizontal before descending 14.66 m downwards and finally being raised 7.33 m again and then restarting the process. During upward motion, stack pressures rise, while they fall during downward motion.

|

|

|

| Rolling is the movement of a ship around its longitudinal axis, the rolling angle in this case being 10°. | ||

Rolling involves side-to-side movement of the vessel. The rolling period is defined as the time taken for a full rolling oscillation from the horizontal to the left, back to horizontal then to the right and then back to horizontal. In vessels with a high righting capacity, i.e. stiff ships, rolling periods of ten seconds and below are entirely usual. Rolling angle is measured relative to the horizontal. Just in moderate seas, even very large vessels roll to an angle of 10°.

|

|

|

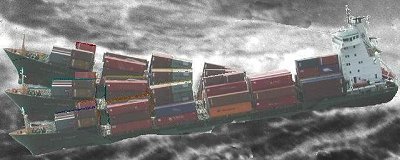

| Rolling angles of 30° are not unusual in heavy weather. | ||

In bad weather, angles of 30° are not unusual. Even the largest container ships must be expected to roll to such angles. Stabilizers and other anti-heeling systems may help to damp ship movements. However, not all systems are usable or sufficiently effective in bad weather.

|

Rolling angle of 45° |

On rare occasions, rolling angles may reach 45° and above. It is easy to imagine what that means for inadequately secured container cargoes.

Rolling and pitching of a vessel generate upward and downward acceleration forces directed tangentially to the direction of rotation, the values of which increase with distance from the rolling or pitching axis and are inversely proportional to the square of the rolling or pitching periods. At an identical distance from the axis, if the rolling or pitching period is halved, acceleration forces are quadrupled, while if the rolling or pitching period is doubled, acceleration forces are quartered. Rolling or pitching angles generate downslope forces. Steeper tilting, as occurs during rolling, promote cargo slippage. As already mentioned, the outwardly acting centrifugal accelerations generated by rotational motion are of no significance in rolling and pitching.

Overall, containers and packages may be exposed to such accelerations for very long periods when at sea. Moreover, the oscillations may be superimposed one on the other and be intensified.

|

|

|

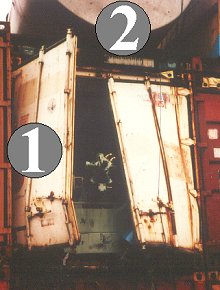

| Damage to containers in rolling motion, caused by inadequately secured cargo: | ||

| left: in a container stowed athwartships | right: in a fore and aft stowed container | |

It must be emphasized that it was not the "hazards of the sea" which caused the damage, but instead inadequate securing inside the container. While such damage has indeed occurred in association with the rolling motion of the ship, the root cause is the "home-grown" acceleration forces arising from shortcomings in packing and securing.

|

|

| Slamming describes the hydrodynamic impacts undergone by a ship. |

Slamming is the term used to describe the hydrodynamic impacts which a ship encounters due to the up and down motion of the hull, entry into wave crests and the consequent abrupt immersion of the ship into the sea.

Vibration from the hull can be transferred to the cargo. Goods are exposed to stresses from the extremely low frequency oscillations generated by sea conditions and by higher frequency machinery and propeller vibration. Such risks can and must be avoided by using seaworthy shipping packages which are fit for purpose.

The absolute acceleration values encountered on board ship are not excessively high. In favorable stowage spaces, they may even be considerably lower than those encountered in land or air transport. In many cases, not even the values stated in the following Table occur. However, the frequency with which the motion occurs must definitely be borne in mind. At a rolling period of 10 s, a ship moves side to side 8640 times daily. Over several days' bad weather, the cargo will thus be exposed to alternating loads tens of thousands of times.

| Mode of transport: ocean-going vessel | Forward acting forces | Backward acting forces | Sideways acting forces |

| Baltic Sea | 0.3 g (b) | 0.3 g (b) | 0.5 g |

| North Sea | 0.3 g (c) | 0.3 g (c) | 0.7 g |

| Unrestricted | 0.4 g (d) | 0.4 g (d) | 0.8 g |

| 1 g = 9.81 m/sec² The above values should be combined with static gravity force of 1.0 g acting downwards and a dynamic variation of: | |||

| (b)= ±0.5g | (c)= ±0.7g | (d)= ±0.8g | |

Extract from a Table in the CTU packing guidelines

In relation to the Table, it is stated in point 1.7 of the CTU packing guidelines that examples of accelerations are given which could arise during transport operations:

-

However, national legislation or recommendations may require the use of other values.

|

Overview of acceleration forces prevailing on board a ship |

Annex 13 of the CSS Code contains tables for determining acceleration forces as a function of stowage space on board, the ship's length and speed. However, these tables are not suitable for use when packing CTUs and securing cargoes in or on CTUs, specifically for the following reasons:

If containers, road vehicles, rail cars or the like and road trailers, roll trailers and semitrailers are loaded inland for maritime transport, their ultimate stowage space on board is unknown. The least favorable conditions should thus always be taken into account. As a rule of thumb, loads of 1 g in the vertical direction and 0.8 g in the horizontal direction should be anticipated for worldwide transport. The shipowner will not accept any attempt by the shipper to specify a particular container slot in advance. Even notes on the bill of lading requiring loading below deck are ineffective. All shipping packages must accordingly be constructed so as to be able to withstand 0.8 times the weight of all adjacently stowed cargo and twice the mass of the cargo loaded on top. If this is not the case, appropriate protective measures must be taken. Additional rigid receptacles, frames, false decks and similar measures may be helpful.

Modern cargo handling procedures and the ships developed for this purpose have made maritime transport faster and cheaper and, in particular, have reduced cargo handling stresses in port. In order to ensure great flexibility in terms of loading and unloading, modern ships, in particular ro/ro freighters and ferries, inevitably have poorer seakeeping ability than conventional general cargo or heavy-lift vessels.

For reasons of stability during loading, they require a high righting capacity. As "stiff" vessels they initially oppose heeling movements with a very high righting moment. The high roll moment of inertia of these vessels entails shorter rolling periods and high transverse acceleration forces. Due to the particular nature of ro/ro shipping, the ship's command is not generally able to influence the stability behavior of these ships by adjusting the weight distribution. The risk of accidents is particularly high because, given the large free surfaces in the ship, overturning cargo and the possible consequent ingress of water may result in an abrupt capsize. Most readers will remember major accidents of this kind. Inadequate cargo securing in transport receptacles such as containers, swap-bodies etc. may consequently have a very significant impact on ship safety.

|

Ro/ro freighter listing as a result of water ingress |

|

|

| Free surfaces on board always increase the risk of capsize. |

"Home-grown" acceleration forces in maritime transport are the commonest cause of cargo damage on board ship.

|

Damage caused by "home-grown" acceleration forces |

Because container packers do not have the appropriate knowledge and skills, they underestimate the effect of gaps in the stow. The consequent motion has a devastating effect on the cargo.

| Damage caused by "home-grown" acceleration forces |  |

"Home-grown" acceleration can readily be identified on board ship if the stowage spaces have been subjected to similar forces, but only some of the goods have suffered damage. It is even clearer when goods stowed in an exposed location remain undamaged, while other goods suffer damage despite being exposed to lower acceleration forces. The cases on the platform at the top left were exposed to higher acceleration forces than the cargoes in the containers, which were stowed beneath or further inwards. Although the cases were only secured with a single belt each, they have only shifted slightly, while the containers and their contents have been completely destroyed.

|

|

|

| Effects of "home-grown" acceleration forces |

In the lower container (1), the poorly secured machine has been set in motion and has forced the container doors open. The tank on the platform (2) stowed above is secured with only two belts and thus also inadequately. Nevertheless, it has withstood the acceleration forces and has slipped only a little. This is a clear indication that the acceleration forces were still relatively slight.

The following pictures clearly show the results of home-grown acceleration forces. It should be noted that almost all of the containers have been exposed to stresses from the inside outwards, i.e. they have bulges rather than dents.

|

|

|

|

|

|

| Bulges in containers as a result of home-grown acceleration forces | ||

|

Container "ripped apart" as a result of home-grown acceleration forces |

The fiber structure of the plywood walls of the container in the picture above clearly reveals that the forces were acting from the inside outwards. The container was destroyed by gaps in the stow. These gaps resulted in extremely high acceleration forces and shocks.

|

|

|

| Damage as a result of home-grown acceleration forces | ||

Annex 13 of the CSS Code provides tools to assist in calculating wind pressure and the effects of spray. The details provided in this publication may possibly be of assistance in dimensioning cargo securing on open containers such as flatracks, platforms etc., but they are otherwise of interest only to the ship's command, but not to container packers working inland. As a rough guide, wind pressure may be estimated, for example for fastening tarpaulins etc., at 100 daN/m². Closed containers are spray-tight provided that they have no technical defects.

|

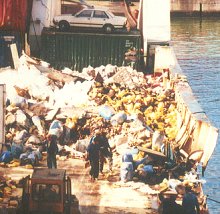

Effects of breaking-wave impact |

Cargoes stowed on deck may be exposed to breaking-wave impact. Even for experts, the magnitude of these forces and their effects are difficult to estimate. Additional securing measures cannot prevent such effects or only to a very limited extent. While securing can never withstand breaking-wave impact, cargoes on open containers should, as a precaution, be secured against floating away.

In conventional shipping, damage prevention is the responsibility of the ship's command. Responsible ship's commands will accordingly use any means available to them to keep the effects of rough seas and breaking-wave impact as small as possible. Cargo officers will stow cargoes which are particularly sensitive or require particularly extensive securing in locations which are subjected to less acceleration. In container trade, no consideration can be given to special requirements with regard to stowage space for particular containers. Moreover, the central stowage planning offices, which prepare initial plans, and the ship's command have no knowledge as to what is loaded in the containers. Dangerous cargo containers are an exception. In this case, the contents are known and the containers receive special stowage spaces.

|

Breaking-wave impact means that "green water" has come onto the deck. | |

| Damage caused by breaking-wave impact |

| Container ripped open by breaking-wave impact |  |

Summary of mechanical stresses arising during maritime transport

In very general terms, it can be stated that cargo transport units may be exposed to very different stresses during maritime transport than they are in road, rail or inland waterway transport. Unless the voyage proceeds very calmly in good weather, the containers and their cargoes will be exposed to oscillation/vibration which is primarily caused by rolling and pitching. It is almost exclusively during rolling, due to the tilt/rolling angles which arise, that shipping packages are pressed against the container walls and are squashed against the walls or the surfaces of adjacent shipping packages. The same occurs in "open" containers if parts of the cargo are pressed against the lashings or bracing. The oscillations of rolling and pitching alternately increase and reduce stack pressure. These changes peak at the moment the motion is reversed. Assuming a vertical acceleration of 1 g, a package can thus alternate between "twice its weight" and "weightless". Appropriate deductions or additions may be made for other acceleration values. When containers are incorrectly packed or the cargoes inadequately secured, the packages may shift, be dented, squashed, jumbled up etc.

|

Jumbled cartons in a container |