The term "cereals" covers the grain fruits of cultivated grasses (wheat, rice, corn, barley, millet, oats (Fig. 112), rye etc.). As a rule, cereals are transported worldwide in bulk carriers, for instance from the USA, Canada, Argentina, India, Indonesia and Australia. Seed and malt etc. are also transported by container.

|

Figure 112: Oats; Photo: U. Scharnow |

With a water content of 11.5 - 15% (see Tab. 1), cereals belong the water content class 2 (WCC 2). The sorption isotherms exhibit a continuous S-shaped profile. As living organs, cereals belong to the category of goods displaying 2nd order biotic activity (BA 2). Cereals require particular temperature, humidity/moisture and possibly ventilation conditions (SC VI). Cereals do not have any particular requirements as to ventilation conditions, if they are introduced into the container in a container dry state and the temperatures and relative humidities can be kept correspondingly low.

| Constituents | Rye, wheat | Rice | Corn |

| Carbohydrates | 68 - 69 | up to 80 | 70 |

| Protein | 11 - 12 | 5 - 7 | 10.5 |

| Fat | 2 | approx. 1 | 4.5 |

| Raw fiber | 2 | 0.3 | 2.5 |

| Ash | 1.5 - 2 | 0.5 | 1.5 |

| Water | 13 - 15 | > 14 | 11.5 |

Table 19: Chemical composition of major types of cereal in % [28]

Seed cereal and malt are transported in bulk containers with appropriate predrying to approx. 12 - 13%. Should standard containers be provided, it is advisable to suspend liner bags of plastic fabric with integral nonwoven fabric in the containers to catch sweat.

The cargo is kept away from the container doors by four rectangular bars, which fit into the container's last pair of corrugations. Once the container has been loaded, the liner bag is closed by means of straps. The container is unpacked by cutting the liner bag open at the bottom and tipping the container.

Bagged seed and malt in particular are also transported in standard containers.

Ventilated containers are favorable, since they may be actively ventilated from outside in order to dissipate moisture and heat. They have to be loaded below deck, in order to allow ventilation to work effectively. This is also true of standard containers: on deck, extreme temperature gradients may occur, especially during winter in the northern hemisphere, which may lead to container sweat or cargo sweat.

The structure and chemical composition of the grain vary little between the different types of cereal (see Table 19). As far as structure is concerned, three constituents of the cereal grain are worthy of further consideration:

- its cracked husk, which gives the grain a greatly increased surface area relative to its mass. This allows the cereal grain to enter into an active exchange of materials with its environment (moisture, odor).

- the endosperm, which constitutes the main component of the grain.

- the embryo (Fig. 113)

|

Figure 113: Longitudinal section through a rye grain 1 - multilayer husk and seed coat 2 - aleurone layer 3 - endosperm 4 - scutellum 5 - embryo |

Hygroscopicity

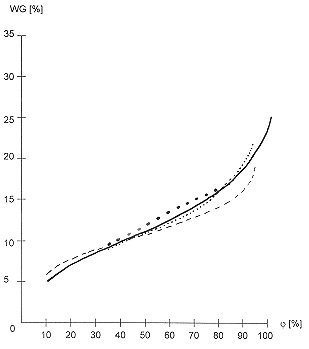

Carbohydrates, especially starch, are the main constituent of a cereal grain. However, when it comes to transport in bulk, standard and ventilated containers, it is the water content that is important. Although, at 11.5 - 15%, the water content is low compared to that of fruit and vegetables, it still plays a considerable part in the respiration processes of the seed cereal. When transporting cereals, it must be remembered that they are living, vegetable organisms whose ability to germinate must be retained. The hygroscopic properties of cereals were described in Section 10.2.2. Fig. 114 shows the most important sorption isotherms for cereals.

|

Figure 114: Sorption isotherms for cereals — rye (20°C) --- rice, hulled (25°C) ···· wheat (20°C) ••• corn (20°C) |

Respiration of the ripe cereal grain

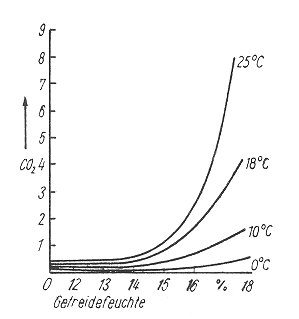

The influence of temperature and water content on the respiration intensity of the cereal grain is illustrated in Fig. 115.

|

Figure 115: Respiration intensity of wheat as a function of humidity/moisture and temperature (development of mg of CO2 per 100 g of dry wheat solids over 24 hours); Herrmann [17] |

Curves 1 - 4 show the respiration intensity of wheat as a function of storage temperature and water content. The following conclusions may be drawn from this illustration:

- At a low water content, the intensity of respiration is low at all temperatures. Even at temperatures of 25°C, respiration intensity is low at water contents of up to 13%. Cereal having a water content of less than 13% is thus deemed to be container dry. With these goods there need be no reservations about suspending ventilation. In the case of container dry cereals, the risk of self-heating is low, since the drier grains absorb the water content from the moister ones.

- At water contents of 14% upwards, respiration intensity begins to increase; at temperatures of 0°C and 10°C respiration remains slight. The respiration of cereal may therefore largely be inhibited by low transport temperatures.

- At water contents > 15%, respiration increases rapidly. If, in addition to the high water content, high temperatures also occur, respiration is further intensified, as shown by the respiration curves for 18°C and 25°C. Rice reacts even more sensitively to moisture because of its higher water content (see Table 19).

- The increase in respiration results not only in the formation of carbon dioxide and moisture but also in increased evolution of heat. Moisture and heat in turn promote the activity of the respiratory enzymes, which bring about more rapid respiration, as a result of which this increase in cereal respiration may result in self-heating.

After harvesting, cereals usually undergo further post-ripening, which consists of the high molecular weight substances congregating further with water being expelled (syneresis). As the surface of the cereal then becomes damp because of the elevated water content, this is described as "sweating". In this state, the cereal is highly susceptible to mold and must not as yet be transported. However, if the water content of the cereal is low (< 13%), proper storage allows the sweat moisture to be absorbed by the air without the risk of mold growth. This sweating process lasts for approximately one to two months.

Composition of the ambient air

The excretion of carbon dioxide by respiring cereals is important from various standpoints. If relatively large quantities of carbon dioxide accumulate in the hold, the respiratory activity of the cereal will drop. In the case of cereal which is container dry, air with an increased carbon dioxide content does not have a negative impact on the quality of the cargo, indeed mold growth is inhibited.

Odor

Cereals are sensitive to the absorption of foreign odors. The considerable absorption capacity of the cereal grain results from its rough surface and the individual shells of the husk and seed coat, which communicate with the external air through cracks. One metric ton of rye has a total surface area of 64,000 m². The resultant large overall surface area explains the elevated odor sensitivity of cereal grains. Gases and aroma substances, such as sulfur dioxide, phenol and kerosene (strong smelling chemicals), are readily absorbed by the cereal. For this reason, containers must be completely odor-free. On the other hand, excessively wet rice, in particular, may spread a penetrating odor.

Damage

The evolution of heat and moisture by the seed cereal has the following consequences:

- The seed cereal may become musty, ferment and turn sour: when moisture levels are excessive, the cereal grains agglomerate and become caked.

- Risk of mold development; rice and corn are at particular risk from mold.

- Risk that seed cereal may lose the ability to germinate. However, if seed cereal is transported in bulk containers at relatively high water contents, i.e. for example wheat with water contents > 14%, the seed cereal must be expected to change over from aerobic to anaerobic respiration due to the build-up of carbon dioxide, which means, among other things, that lactic acid bacteria, which are able to tolerate an anaerobic environment, can also develop. The fermentation products carbon dioxide, lactic acid and alcohol have an impact on the seed cereal, since these fermentation products have a toxic effect on the grain germ, and the seed loses its ability to germinate if stored in an oxygen-depleted environment.

- Risk of premature cereal germination, which constitutes serious damage in the case of seed.

- Risk of infestation by animal pests, which, at favorable temperatures, may develop well even at water contents < 14%.

- The evolution of moisture and heat by microorganisms and animal pests due to respiration, which may accelerate self-heating of the cereals (see Section 13.12).

- Risk of self-heating. Rice and corn have a particular tendency to undergo self-heating.

- Risk of rancidity. Due to its relatively high water content, rice in particular has a tendency to become rancid owing to the formation of free fatty acids; this risk is particularly great in the case of brown rice because of the oil-containing silver skin.

- When packing containers at the place of departure, it must be remembered that hygroscopic seed cereal can reabsorb moisture during storage in moist, tropical air. In areas with dry and rainy seasons, the transport date must be noted.

The seed, especially rye seed, must be carefully cleaned due to infestation with toxic ergot (see Figs. 116, 117).

|

|

| Figure 116: Ears of rye with ergot; Photo: U. Scharnow |

Figure 117: Ears of rye with ergot; Photo: U. Scharnow |