In practice, all hard boards lose strength when damp, so meaning that the stack height for fruit cartons has to be limited, at normal water content, to nine layers for a six week voyage, to prevent the stack from collapsing.

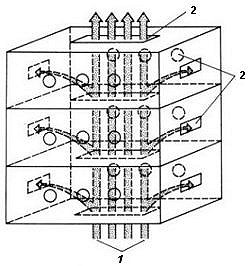

If wet strength cartons are not used, there is a risk, over a longer voyage, of the cartons collapsing and the fruit becoming damaged due to pressure. This also leads to a reduction in the air openings and thus in the volume of circulating air (see Fig. 102).

|

Figure 102: Vertical air flow through perforated cartons 1 - vertically flowing cooling air 2 - perforations in cartons |

To improve the wet strength of cartons, the paperboards are generally rendered water repellent (by waxing, coating or impregnation).

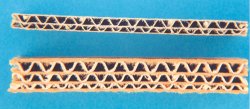

In folding telescope cartons, the lid parts generally consist of single wall corrugated board (CB 1, see Table 6) and the base parts of double wall corrugated board (CB 2, see Fig. 105), for greater strength.

| Cargo type | Exporting country |

Packaging container |

Packaging material |

Tare in g |

Total tare in g |

Perforation content in % |

| Grapefruit | Cuba | Folding telescope carton |

D WP 1 B WP 2 |

D 350 B 550 |

900 | 1.68 |

| Tangerines/ Mandarins |

Cuba | Folding telescope carton |

D WP 1 B WP 1 |

D 340 B 400 |

740 | 1.65 |

| Mandarins | Uruguay | Folding telescope carton |

D WP 1 B WP 1 |

D 400 B 640 |

1,040 | 2.15 |

| Oranges | Uruguay | Folding telescope carton |

D WP 1 B WP 2 |

D 500 B 780 |

1,280 | 2.13 |

| Bananas | Ecuador | Folding telescope carton |

D WP 1 B WP 2 |

D 450 B 600 |

1,050 | 8.18 |

Table 6: Perforation content of shipping cartons for the transport of tropical and subtropical fruits

| L - Lid part | CB 1 - Corrugated board, single wall |

| B - Base part | CB 2 - Corrugated board, double wall |

At an equilibrium moisture content of 65 - 70%, the water content for corrugated board is 5 - 8%. Complaints should be lodged if cartons are obviously of inadequate strength.

|

Figure 105: Single wall corrugated board (top), Double wall corrugated board (bottom) |