The freezing curve can be divided into chilling and ice separation stages. Crystallization of ice once the temperature falls below the freezing point increases the concentration of the solution, so depressing the freezing point of the remaining liquid. The water freezes gradually over a wide temperature range until the eutectic point, at which the water and solutes crystallize out together, is reached at about -62°C.

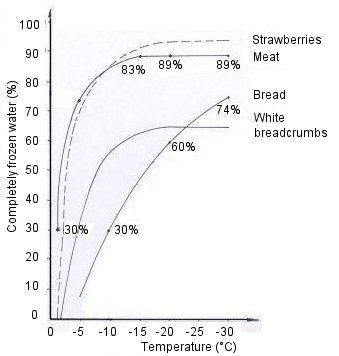

Figure 97 shows the quantity of crystallized ice in various foodstuffs as a function of freezing temperature. While in strawberries and meat 70% of the water is completely frozen at between -1 and -5°C, only 30% of the water in white breadcrumbs is frozen at such temperatures. At temperatures below -10°C, only a little further water freezes in strawberries and meat. The freezing process is virtually complete for white breadcrumbs only from -20°C and for strawberries and beef only from -30°C.

This freezing curve explains why frozen goods are generally frozen to core temperatures of -18°C to at most -30°C. Some 0.3 - 0.49 g of water/kg of dry solids remain in the tissue as residual liquid. Even at lower temperatures, this residual liquid does not freeze, and is sufficient to permit enzyme activity.

|

| Figure 97: Proportion of completely frozen water in various foodstuffs from the onset of freezing to -30°C [57] |

Frozen goods thus do not have an unlimited storage life, but are instead classed as preserved foods. The low-temperature containers described in section 15.3.1.3 are an exception.

At temperatures of -60°C, virtually 100% of the water has frozen and, theoretically, the goods have an unlimited storage life. The conventional industrial rapid freezing process (flash freezing) which uses freezing plant capable of operating at a freezing rate of 1 cm/h or more ensures that the cell structure is largely retained and consequently little drip loss occurs on thawing, i.e. the quality of the frozen goods is maintained.