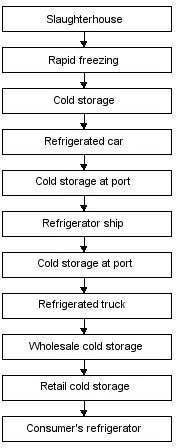

Figure 96: Diagram of cold chain |

The refrigeration capacity required to chill the foodstuffs is determined by the specific heat capacity of the goods over the chilling range, by the temperature of goods before and on completion of chilling, by the storage temperature and the chilling time. The cold chain is the unbroken chain of storage facilities and means of transport from the manufacture through to the consumer in which the prescribed freezing temperature is constantly maintained (see Fig. 96). The cold chain must keep the foodstuffs at an uninterrupted, uniform temperature so that they reach the consumer without suffering loss of quality. Accordingly, one of the crew's duties is to ensure strict compliance with transport temperatures from when the cargo is accepted until it is unloaded. The greater the sensitivity of the cargo, e.g. stored blood, the faster must the refrigerated container be reconnected at the terminal or for onward transport. |