In general, therefore, an optimum humidity range of 85 - 90% is recommended for the refrigerated transport and fruit and vegetables while a value of up to 95% is recommended for frozen meat.

Although low humidities inhibit the activity of microorganisms, weight losses (shrinkage/shortage) soon occur as a result of drying out, these being known as transpiration losses (evaporation losses) in the case of goods of vegetable origin. Such goods can no longer replace the water lost by transpiration, the inner pressure in the cells (turgor) falls and the goods shrivel and consequently suffer losses of weight and vitamin content.

The degree to which the goods dry out is dependent on three factors: relative humidity, temperature and air movement.

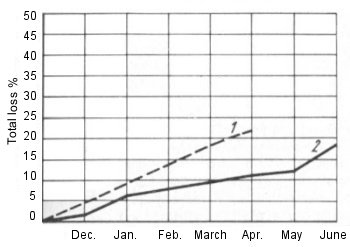

Drying-out and weight losses are the greater, the lower is the relative humidity of the refrigerated container; storage temperature is the decisive factor: at identical relative humidity, a product dries out more slowly, the lower the container temperature. Chilling and freezing temperatures reduce shrinkage/shortage. Fig. 83 compares the weight losses in apples when chilled and stored at normal temperatures. However, even at relative humidities of 90%, if a small partial pressure gradient exists between the surface of the frozen cargo and the ambient air the marginal layers of unpackaged goods can dry out considerably; in extreme cases, meat, for example, may suffer freezer burn, so called because of the associated sharply defined, dried-up, light grey/yellowish areas.

Even after thawing, the dried-out cargo remains strawy and dry, the damage being irreversible. In the case of packaged goods, drying out may occur within the package (in-package desiccation) if there are cavities and temperature differences between the product and the packaging.

|

| 1 Storage at normal temperatures 2 Chilled storage |

| Figure 83: Weight loss in apples (Clivia variety) when stored at normal temperatures and chilled [29] |