|

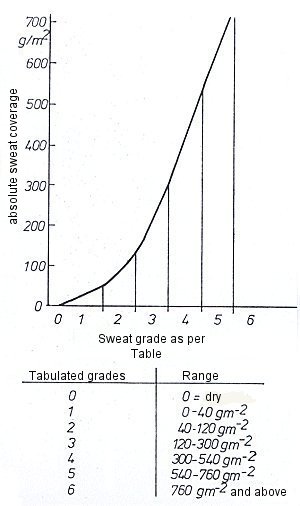

Figure 23: Absolute quantity of sweat in g/m² according to sweat classes; Svenson [54] |

Fig. 23 shows the determined absolute quantities of sweat in g/m² according to sweat classes, i.e. the number of grams of sweat present on one square meter of surface at the individual classes. Table 1 shows the observation features for classification of sweat classes. The loss adjuster can use these features to make a good assessment of sweat damage.

| Class | Feature | Quantity of water in g / m² |

| 0 | No sweat | 0 dry |

| 1 | Surface feels moist (not just cold). | 0 - 40 |

| 2 | Sweat can be swept together with the hand and then runs off. | 40 - 120 |

| 3 | Distinct droplets formed. Individual droplets run down vertical walls. | 120 - 300 |

| 4 | Surfaces densely occupied with large droplets, which frequently run off vertical surfaces | 300 - 540 |

| 5 | Isolated dripping from the ceiling, constant run-off from vertical surfaces | 540 - 760 |

| 6 | Severe dripping from ceiling, puddles formed at the bottom of vertical surfaces | 760 and above |

Table 1 shows the observation features for classification of sweat classes;

U. Scharnow

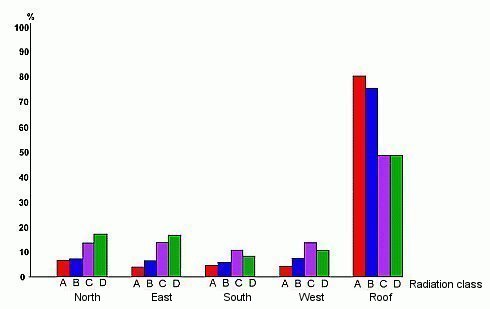

Fig. 24 shows sweat formation on a container ceiling. The differences in sweat formation of the individual boundary surfaces depending on their exposure and the variable occurrence of sweat classes under different radiation conditions are of particular significance.

|

Figure 24: Container sweat: sweat class 4; Photo: Schieder [18] |

See in this connection Fig. 25, which shows the percentage frequency of the occurrence of sweat classes on the individual boundary surfaces of the container. The most remarkable features are the extremely high percentage of the occurrence of sweat on the container ceiling, together with the extremely low percentage frequency of occurrence of sweat class 0. The Figure also shows, for example, that the south wall of the container exhibits the lowest risk of sweat formation. This is manifested in that sweat class 0 is found to occur most frequently in both classes on the south wall, while distinctly lower frequencies are observed for the higher sweat classes. On the basis of the distributions shown here and of other investigations, it is clear that the greatest quantity of sweat always occurs on the container roof. This also tallies with investigations into the mechanism of sweat formation in containers. This fact is of particular significance because sweat on the walls can run off without causing major damage, while sweat on the roof drips directly onto the cargo and so constitutes the greater risk.

|

| Figure 25: Frequency of occurrence of sweat on the boundary surfaces of a container; U. Scharnow |

Another conclusion which may be drawn from Fig. 25 is that more sweat is formed as radiation conditions improve. Goods packed in a container are exposed to a much lower level of risk under conditions with little radiation than under good radiation conditions.

The moisture equilibrium, which may also be stated as the temperature/dew point difference (see section 10.2.6), is a significant factor in sweat formation. If the equilibrium moisture content of the product is low, for example at 60% relative humidity, the air temperature/dew point difference is approx. 8°C, i.e. nocturnal cooling of the container wall must be 8°C for the air temperature at the container wall to fall below the air's dew point. At a higher equilibrium moisture content, for example of 75%, a drop in temperature of 5°C is sufficient to trigger condensation.

Since the equilibrium moisture content is a function of the product's water content, it is consequently important to pack hygroscopic goods into the closed container in the driest possible state (container dry). The lower is the water content of the goods packed, the lower too is its tendency to form sweat in the container.

There is a risk of sweating if containers are transported from a warm region into a colder climate and are not rapidly unpacked. For example, three containers packed with coffee at the cargo temperature of 18°C were unpacked at different times while the external temperature was close to 0°C. The first container was opened immediately and emptied. It had severe sweat on the ceiling, which was also dripping down, but the coffee suffered no damage as a consequence.

The second container was unpacked one day later and exhibited considerable sweat damage taking the form of a soaked uppermost layer.

On the third day, the third container was unpacked: the contents were severely soaked and there was distinct mold growth.

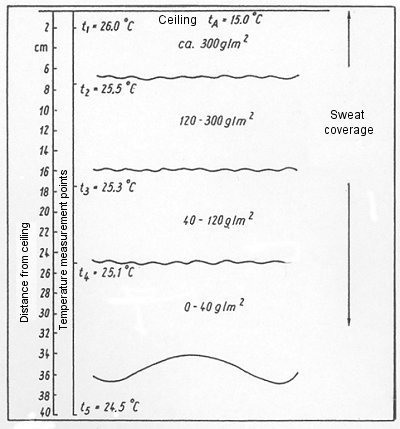

Fig. 26 shows the measured sweat coverage in a standard container exposed to radiation in high summer in Central Europe at depths of 0 - 40 cm; from a level of 300 g/m² in the topmost centimeters, coverage drops to 0 - 40 g/m² at a depth of greater than 25 cm.

|

| Figure 26: Measured sweat coverage in a standard container exposed to radiation (Central Europe, high summer); Svenson [55] |

The following loss prevention measures are recommended to avert sweat damage:

- unpack container quickly if the cargo temperature is still higher than the external temperature

- lay paper dunnage in order to absorb sweat

- lay out a plastic sheet with a condensation reservoir, fix some nonwoven fabric in place

- provide desiccants