|

||

| Inadequately secured concrete pump | ||

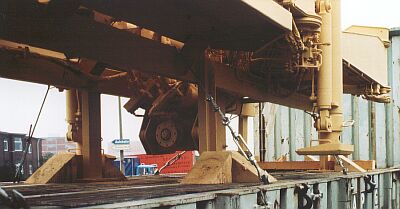

Considerable effort has been made to secure this concrete pump. However, the securing action achieved thereby is minimal because of the nonuniformity of the wire rope lashings used. It is incomprehensible why the lashing reels incorporated into the flatrack have not been used.

|

||

| Securing material wastage | ||

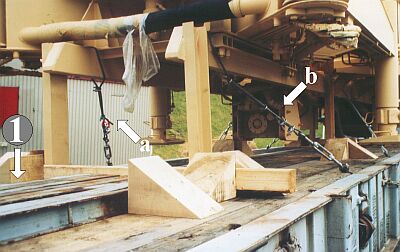

The wedges used have been incorrectly cut and their efficacy is minimal. They weren't basically even necessary. The wire rope lashings are nonuniform and only some of the possible maximum securing load has been achieved.

The use of tie-down lashings is particularly ridiculous, since the frame of the concrete pump can move freely sideways in them:

|

Tie-down lashing over the frame parts of the concrete pump |

|

||

| Material wastage due to pointless, nonuniform securing | ||

Securing of the stanchions of the flatrack is unnecessary, since the flat has stanchion pockets at the side in which the stanchions can be inserted when not in use. None of the wire rope lashings applied are uniform. This will be explained with reference to the two lashings (a) and (b).

|

||

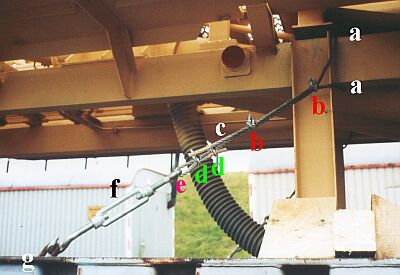

| Nonuniform wire rope lashing | ||

A 12 mm diameter steel wire rope was used with a maximum securing load of 5,760 daN per single run. The following are the values for the maximum securing load of the individual components of the lashing or at the various points of the lashing:

| a | As a result of deflection around sharp edges, load can be calculated as 2 times working parts each of 5,760 daN x 0.25 = | ~ 2,880 daN |

| b | Two wire clips have been positioned with the bow on the working part. In addition, they have clearly not been tightened enough, meaning that the strength of the connection cannot be calculated. At any event, it is less than 2,880 daN. | < 2,880 daN |

| c | Loose or non-working part. This is where the shackles should have been placed. | |

| d | These two wire clips have been correctly positioned and tightened more firmly. If the correct tightening moment has been achieved, a strength is obtained in conjunction with the curvature of e of 2 parts each of 5,760 daN x 0.5 = | ~ 5,760 N |

| e | Diameter of curvature corresponds to cable diameter | |

| f | Maximum securing load of turnbuckle approx. | ~ 4,000 daN |

| g | Maximum securing load lashing point approx. | ~ 4,000 daN |

With virtually the same length of wire and the same number of wire clips, but a different way of proceeding, the following values could have been achieved:

|

At point of connection

to frame:

5,760 daN

to frame:

5,760 daN

|

At point of connection

to turnbuckle:

5,760 daN

The weak points in this variant are the lashing ring recessed into the flatrack floor and the turnbuckle with a maximum securing load in each case of 4,000 daN.

If the lashing bars fitted to the side of the flatrack with a maximum securing load of approx. 6,000 daN are used, the maximum securing load of a lashing may be increased. Compared with the maximum securing load of less than 2,880 daN which was originally achieved...

|

||

| The maximum securing load of this lashing amounts to less than approx. 2,880 daN. |

||

.... 5,760 daN maximum securing load may then be achieved per lashing.

|

||

| The maximum securing load of this lashing amounts to 5,760 daN |

||

Since the forces are distributed to the working parts, even a turnbuckle of only approx. 3,000 daN could be used.

The concrete pump could easily have been secured to the flatrack with a total of four lashings, see below:

|

|

| Diagram showing the principle of adequate securing with four direct lashings |

|

||

| Diagram showing the principle of lashing and the horizontal components |

||

The longitudinal and transverse components are identical. The vertical components are somewhat smaller per lashing. However, since all the lashings have this vertical component, wholly satisfactory securing is achieved.