|

Lashing point on a 40' flat |

The same rules of thumb apply for lashing points made of normal strength steel as for lashing shackles and lashing turnbuckles. The diameter of the ring material or the bars is critical.

| Breaking load | MSL factor | MSL | ||

| d x d x 20 | x 0.50 = | kN | (diameter in cm) | |

| d x d x 20 | x 0.50 = | daN | (diameter in mm) | |

|

Determining the diameter of a lashing point: 20 mm |

| MSL lashing point material diameter 2.0 cm = 2.0 x 2.0 x 10 = 40.0 kN |

| MSL lashing point material diameter 20 mm = 20 x 20 x 10 = 4,000 daN |

|

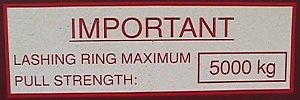

Notice indicating the strength of a lashing point |

Even if it is not entirely clear what is meant by a strength specification, the MSL should still be calculated using the rule of thumb.

|

|

|

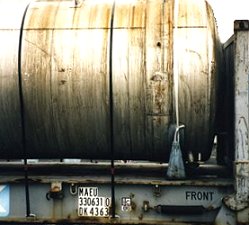

| Load on lashing points |

Loads may only be applied to lashing points in a permissible manner. If a number of lashings are attached to a single lashing point, the total load must be taken into account. If lashings attached to the same lashing point are alternately subjected to load and relieved of load, every lashing can have the full MSL. If the lashings subject the lashing point to load simultaneously, the MSLs of the lashings must be distributed accordingly.

|

|

|

| Steel strapping, untreated | Steel strapping, blued |

Steel strapping can be applied quickly and easily and is therefore suitable for securing purposes on many loads.

The following values can be used for calculations for untreated steel strapping:

| Breaking load | MSL factor | MSL | ||

| Strap width w x strap thickness t | w x t x 70 | x 0.70 = | kN | (measurements in cm) |

| Strap width w x strap thickness t | t x w x 70 | x 0.70 = | daN | (measurements in mm) |

Blued straps have a higher strength. It can be calculated using these values:

| Breaking load | MSL factor | MSL | ||

| Strap width w x strap thickness t | w x t x 85 | x 0.70 = | kN | (measurements in cm) |

| Strap width w x strap thickness t | t x w x 85 | x 0.70 = | daN | (measurements in mm) |

A blued steel strap 32 mm wide and 1.6 mm thick would produce the following value for the MSL:

| MSL for blued steel strap 36 mm wide, 1.6 mm thick = 3.2 x 0.16 x 85 x 0.7 = 30.464 kN |

| MSL for blued steel strap 36 mm wide, 1.6 mm thick = 32 x 1.6 x 85 x 0.7 = 3,046.4 kN |

The dimensions of steel straps are often coded without specifying the dimension units. It is usual practice to encode the width in mm and the thickness in 0.1 mm. The strap referred to above would have the designation 32/16 steel strap.

|

Lashing point for steel strap as it is rounded |

Strength values calculated by rule of thumb must not be used if the steel strap is used incorrectly.

| Another important requirement is that the strapping seals are applied correctly. |  |

Steel straps have a very high breaking strength and this is a common selling point. The disadvantage of steel straps, however, is their low elasticity. This ranges from around 0.25% to a maximum of 0.5%. Steel straps are therefore not really suitable for use as tie-down lashings.

|

|

|

| Steel straps are utterly unsuitable as tie-down lashings. | ||

For instance, if a lashing is 7 m long, an ordinary commercial steel strap would have an elasticity of 7 m x 0.0025 = 0.0175 m or 17.5 mm. About half of this is exhausted for pretensioning, which means that just 8-9 mm remains. If the circumference of the lashing is reduced by this amount due to the strap cutting into the wood of cases, shifting of goods etc., the steel strapping will become loose and no longer able to fulfill its function as a securing aid. Further jolts during transportation then produce greater forces on account of the resulting acceleration forces which can cause the steel strapping to tear.

|

Compensating for the low elasticity of steel straps |

The low elasticity of steel straps can be compensated for by padding with materials with a high degree of elasticity and recovery. It is generally more convenient to use steel straps for direct lashings. They are extremely suitable for this:

|

|

|

| Loads ideally suited for securing with steel straps | ||

|

|

| Lashing chain with long links |

| Lashing chain with short links |

Lashing chains are generally only used to secure container cargoes if the chains will be returned. On very valuable cargoes, however, it may also be worthwhile to use them as a "lost load securing aid", because of the benefits offered by their high strength and speed with which they can be deployed.

Since lashing chains are made of high strength steel, there are no rules of thumb for calculating the breaking loads. The manufacturer's specifications should be observed. The MSL may be assumed to be 50% of the breaking load. A range of different tensioning mechanisms are used with chains. Errors are frequently made when using these aids.

|

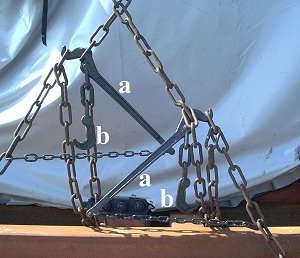

Error made using a lashing chain with tensioning lever (a) and hook (b) |

| Tightening the chain using the hooks: |

||

|

|

|

| Inserting the hook | Shortening the chain | |

| Tightening the chain with the tension lever: |

||

|

|

|

| Inserting the tensioning lever | Tightening and securing the lever | |

|

|

||

| Incorrect | Correct |

The tension levers must not remain at an angle of 90°. They must be adjusted to an angle of at least 45°. Otherwise, the tongues could buckle or shear off.

|

|

|

|

| Lashed with hook | Hook incorrectly inserted | ||

|

|

|

| Permissible shortening of chains | ||

|

|

| Correct shortening of a chain - no chain link is trapped |

|

|

| Incorrect shortening of a chain - a chain link is trapped |

|

|

|

|

|

|

| Shortening a chain with special claw hooks and securing lever |

|

|

|

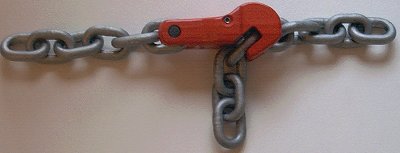

| Chain tensioner (load binder) |

Shortening hook on tensioner |

No rules of thumb are provided in the CSS code for high strength chains, because the diversity of the products is very high. There are chains made to all kinds of different standards on the market. If the stamp on the chain and its accessories clearly identify it as quality class 8, the rule of thumb d² x 120 can be used to calculate the breaking load. The MSL is to be assumed to be 50% of the breaking load. This produces the following figures for the following diameters of chain steel:

| Diameter of steel | Breaking load | MSL factor | MSL |

| 0.6 cm 6 mm |

43.2 kN 4,320 daN |

0.5 0.5 |

21.6 kN 2,160 daN |

| 0.8cm 8 mm |

76.8 kN 7,680 daN |

0.5 0.5 |

38.4 kN 3,840 daN |

| 1 cm 10 mm |

120 kN 12,000 daN |

0.5 0.5 |

60 kN 6,000 daN |

| 1.3 cm 13 mm |

202.8 kN 20,280 daN |

0.5 0.5 |

101.4 kN 10,140 daN |