|

Friction loop made of steel strapping |

The best-known and most frequently used form of friction securing is the round turn or friction loop. The VDI guidelines and other road traffic publications refer to this method as tying down, and to the lashing as a tie-down. The rail transport industry uses the term tie-down.

Whatever term is used, the guidelines are referring to the same method: With the aid of tensioning elements, a certain degree of pretensioning is introduced into the lashings which effectively puts additional artificial weighting on the secured package. This causes additional frictional forces on the bottom of the package. In conjunction with the "normal" frictional forces this will give the overall securing force of a given lashing. The effectiveness of this method of securing increases with the friction and the effective pretensioning.

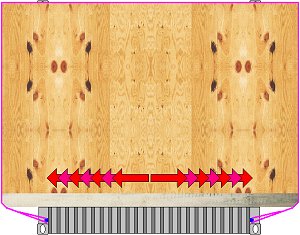

If tie-down lashings can be referred to as "advantageous" at all, this is as a result of fact that the frictional forces act in all directions. Thus, it is not significant from which side of the object the tie-downs are applied.

|

|

|

| Frictional forces act in all directions. | ||

The general securing principle is that the vertical components of the pretensioning force introduced to the lashing aid increase the downward pressure between the load and the surface it is resting on, thus generating additional frictional forces.

|

How tie-downs work |

The smaller the vertical components and the frictional values, the lower the securing forces that can be achieved:

|

|

| The relationship between pretensioning and the vertical component for lashing angles |

Where tensioning aids are applied to just one side of an object, the pretensioning force decreases towards the opposite side. The rougher the contact surfaces over which the material passes, the lower the pretensioning force on the opposite side. The use of smooth edge protectors helps to ensure that as much of the pretensioning force created on the one side is distributed to the other as possible. Jolting may cause the pretensioning force on the tensioned side to decrease and to increase on the side that is not tensioned.

|

|

| Migration of pretensioning force during transport |

If it is not possible to use smooth edge protector corners with tensioners used on one side only, it is sensible to tension the lashings on alternate sides.

|

|

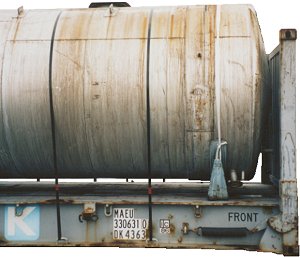

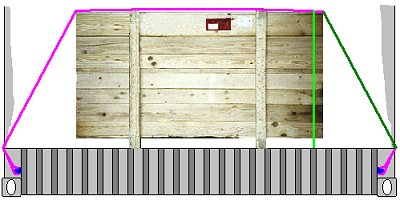

| Incorrect installation of fixed lashing tensioners and steel strapping |

The lashing capstans would have been more useful if three of them had been installed on each side of the flatrack. Here, it is not ideal that all the steel straps are tensioned on the same side.

What is important is that the pretensioning force always remains constant. Thus, it is only sensible to use tie-downs with elastic materials. Wire rope, chains and even steel straps are unsuitable for use as tie-downs unless they can be rendered elastic by the use of special padding materials.

|

|

||

| The securing forces only exist if the pretensioning force can be maintained. | |||

This wooden case clearly shows that the steel strapping has left an impression in the wood of the case. Just a few more jolts and the pretensioning force will be reduced to nothing. The use of a piece of tire rubber, as shown in the picture on the right, can effectively help maintain the pretensioning force by making use of the elasticity of the rubber.

|

|

||

| Steel wire and tire rubber | Decrease in the pretensioning force |

When transporting materials that give way easily, a padding with a high degree of recovery, like tire rubber, is not going to be very effective. As the picture shows, the loss of pretensioning force is dramatic. Here, a new 16 mm steel wire rope lost tension, dropping from approximately 2,700 daN to approximately 2,100 daN during a 20 minute coffee break. Unfortunately steel wire ropes tend to lose tension. In this example, however, the use of tire rubber is an ideal method of reducing damage to the tarpaulins and to the load.

The magnitude of the pretensioning forces that can be introduced into the lashing material is dependent on the tensioning forces used, the leverage on the tensioning element and the elasticity of the lashing material. Experience shows that the following lashing materials are able to attain the following pre-tensioning forces in the lashing material when tensioned with normal physical effort:

- Normal ratchet tensioners approximately 300 daN per side

- Tensioner for single-use webbing approximately 500 daN

- Long-lever ratchet tensioners approximately 500 - 750 daN per side

- Commonly available spindle tensioners and capstans 500 - 1,000 daN

- Manual steel strap tensioners 1,000- 1,500 daN

- Lashing turnbuckles approximately 3,000 daN

For reasons that will not be explained here, the pretensioning force is only permitted to be, at the most, half of the MSL or the permitted lashing force of a single lashing.

The vertical component of the pretensioning forces decreases as the lashing angle of the tie-down decreases. From a mathematical point of view, the rate of decrease is by the sine of the lashing angle. The following values can be used as guidelines:

| Lashing angle | Magnitude of the vertical component | Graphical representation | ||

| 90° | 1.00 | or | 100 % |  |

| 75° | 0.97 | or | 97 % | |

| 60° | 0.87 | or | 87 % | |

| 45° | 0.71 | or | 71 % | |

| 30° | 0.50 | or | 50% | |

| 15° | 0.26 | or | 26% | |

| 0° | 0.00 | or | 0% | |

Influence of the lashing angle on the vertical component

The table below shows examples of the magnitude of the overall securing forces of tie-downs with a total pretensioning force of 600 daN when used with various lashing angles and coefficients of friction.

| Total pretensioning force in daN |

Lashing angle | Vertical component |

Friction | ||||||

| 0.10 | 0.20 | 0.25 | 0.30 | 0.40 | 0.50 | 0.60 | |||

| 600 | 15° | 0.26 | 16 | 31 | 39 | 47 | 62 | 78 | 94 |

| 30° | 0.50 | 30 | 60 | 75 | 90 | 120 | 150 | 180 | |

| 45° | 0.71 | 43 | 85 | 107 | 128 | 170 | 213 | 256 | |

| 60° | 0.87 | 52 | 104 | 131 | 157 | 209 | 261 | 313 | |

| 90° | 1.00 | 60 | 120 | 150 | 180 | 240 | 300 | 360 | |

Securing forces depending on pretensioning force, lashing angle and

friction

The table shows that with a total pretensioning force of 600 daN, a lashing angle of 90° and a coefficient of friction of 30% it is possible to achieve a securing force of 180 daN per tie-down. Thus, in order to secure a load with a mass of 9 t, 50 (fifty !) tie-downs will be required. This shows that tie-downs have only limited use as securing aids. In addition to this, tie-downs require an equal distribution of the pretensioning force on both sides. This can be achieved by using tensioning elements in pairs, centrally or alternately.

The effective securing forces can be very accurately calculated on site with very little effort and some basic mathematics, as long as the pretensioning and frictional forces are known or can be estimated with some accuracy.

|

|

| Determining the vertical component of the pretensioning force of a lashing |

The effective length of the lashing aid in the example is measured at 1.00 m (dark-green line). The vertical component of the lashing in the example is 0.80 m (light-green line). The vertical component of the pretensioning force is thus 80% or 0.8 (always divide the smaller value by the larger value). Multiplying the value with the pretensioning force of the lashing aid and the coefficient of friction between the package and the surface will give the securing force. With a pretensioning force of 500 daN and coefficient of friction of μ = 0.3, the lashing applies a securing force of 0.8 x 500 daN x 0.3 = 120 daN.

Using conventional materials it would be possible to use tensioners on both sides - but this is not practical. The central use of tensioning aids in container loads is a potential source of accidents since staff need to climb on top of the load. Prefabricated load securing materials usually only have tensioning elements that are not located in the middle and would thus require additional outlay in terms of material and work. Thus, it is recommended that tie-downs should be secured on alternate sides if they are used at all. Shifting of the load is more likely to occur if the tension is not distributed equally. Tie-down lashings can only be used in box containers under certain circumstances. They are easy to use with all forms of platform container, but are not to be recommended.

As has already been mentioned, in order to ensure adequate securing of the load, it is necessary to maintain the pretensioning during the entire transportation process. Even the slightest of gaps in the load, the settling of the load, yielding or compression of the load, or the cutting of lashing aids into the load as a result of a lack of edge protectors can all reduce the pretensioning force to zero.

Loads which have an overhang are unsuitable for tie-down lashings for another reason:

|

Potential movement of the load caused by too little securing force applied to a wide load |

As a result of the unsuitable lashing angle in the lower area, it will be practically impossible to attain sufficient pretensioning force regardless of the type of lashing material used. Thus, the risk is particularly high that the package will shift during transport.

|

|

||

| Poor | Not good, but better |

To summarize, friction loops or tie-downs can only really be used as an effective form of securing if there are no gaps in the stow, or if any gaps are filled. With small gaps, the use of wedges or tapered blocks is recommended. Larger gaps in the load should be braced using wood or another equally strong material. It must also be possible to create sufficiently high pressure. If this is not possible, loads should be secured using other methods. Lashing materials without sufficient elasticity are not suitable for use as tie-downs. Those with a suitable degree of elasticity, for example lashing straps, will gradually lose their pretensioning force during use. This process will be accelerated if the load is exposed to vibrations.

Tie-downs must thus be checked and, if necessary, tightened at regular intervals. Since this is not possible when a load is stowed in a container, tie-downs are not suitable for securing loads inside containers. Again: If another method of load securing can be used, tie-downs should be avoided!

One thing tie-downs always do is to create a direct lashing acting against vertical movement.

Friction securing can also be achieved using wedges. Another variation is to to put pressure on the load forcing it down. In the event of an absence of available/accessible lashing points, this method of securing may be used in box containers. The prerequisite is the accessibility of components of the means of transport that are able to withstand this load.

|

Principle of downward pressure - Example |

Depending on the magnitude of the securing forces to be created, the sensitivity of the packages and the resilience of the components of the means of transport, squared lumber, planking and boards can be used. Caution: At very sharp angles, driving the diagonal stays in laterally can create extreme vertical forces.