The aim of the Convention is to achieve the highest possible level of safety of human life in the handling, stacking and transporting of containers. The Convention applies to all containers used for international transport, except containers developed especially for air travel.

Article III, entitled "Application" states:

-

2. Each new container shall be approved either in accordance with the provisions for type-testing or for individual testing as contained in Annex I.

The Convention specifies precise requirements which individual components must meet. Annex II of the CSC gives examples of structural safety requirements and tests. According to the CSC,

-

a container made from any suitable material which satisfactorily performs the following tests without sustaining any permanent deformation or abnormality which would render it incapable of being used for its designed purpose, shall be considered safe. ...

Every contracting state must ensure that effective procedures are put in place to enforce the regulations in Annex I of the Convention. This Annex sets out regulations for the testing, inspection, approval and maintenance of containers. However, the text of the Convention does allow duly authorized organizations to be entrusted with all these tasks, other than maintenance. In many countries, the national classification societies are entrusted with these tasks, e.g. Germanischer Lloyd in Germany.

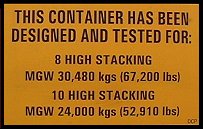

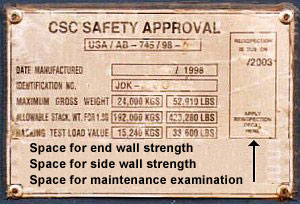

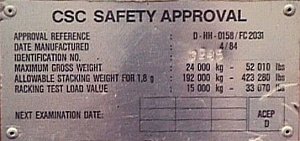

A Safety Approval Plate must be permanently affixed to every container at a readily visible place, where it cannot be easily damaged.

|

CSC plate |

The Plate shall contain the following information in at least the English or French language:

- "CSC SAFETY APPROVAL"

- Country of approval and approval reference

- Date (month and year) of manufacture

- Manufacturer's identification number of the container or, in the case of existing containers for which that number is unknown, the number allotted by the Administration

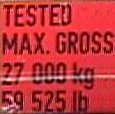

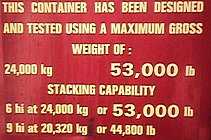

- Maximum gross weight (kilograms and lbs)

- Allowable stacking weight for 1.8 g (kilograms and lbs)

- Transverse racking test load value

The Safety Approval Plate (...) shall take the form of a permanent, non-corrosive, fire-proof rectangular plate measuring not less than 200 mm by 100 mm. The words "CSC Safety Approval" of a minimum letter height of 8 mm and all other words and numbers of a minimum height of 5 mm shall be stamped into, embossed on or indicated on its surface in any other permanent and legible way.

|

|

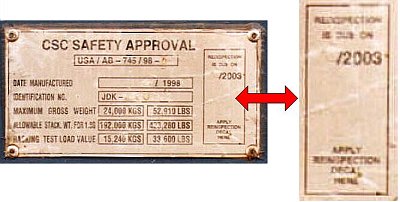

| Test plate from American Bureau of Shipping |

- Date (month and year) of manufacture is year: 1998 and month: September (stated according to ISO standard as 98-9).

- Manufacturer's identification number of the container is JDK ...and so on.

|

|

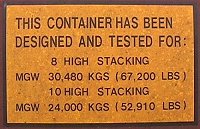

- Allowable stacking weight for 1.8 g (kilograms and lbs). According to ISO standards, fully loaded containers must be stackable six high. The container given by way of example may be stacked 192,000 high (192,000 kg ÷ 24,000 kg = 8).

|

|

|

|

- Transverse racking test load value.In this instance, this value is 15,240 KGS or 33,600 LBS.

|

Transverse racking test |

The values stated for the racking test are approximately in line with the standard; if the stated units of mass (kilograms) are converted into newtons, a slight difference remains.

The longitudinal racking test value is not stated on the CSC plate.

|

| Longitudinal racking test |

The test must be performed from both sides. The ISO standard requires loading of only 75 kN, Lloyd's Register requires 100 kN and Germanischer Lloyd applies 125 kN in its tests.

|

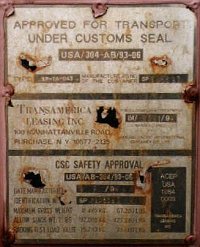

If important, legally prescribed data are no longer visible, a complaint should be lodged. |

| Damaged Safety Approval Plate |

|

CSC plate |

- ... The country of Approval should be indicated by means of the distinguishing sign used to indicate country of registration of motor vehicles in international road traffic. ...

|

The F in the above example stands for France. BV is the abbreviation for the classification society Bureau Veritas, which operates in France. |

| Test plate from Bureau Veritas |

Paragraph 2 b) states):

-

A blank space should be reserved on the Plate for insertion of end and/or side-wall strength values (factors) in accordance with Regulation 1, paragraph 3 and Annex II, texts 6 and 7. A blank space should also be reserved on the Plate for first and subsequent maintenance examination dates (month and year) when used.

The CSC Safety Approval Plates illustrated above do not carry these details. With good reason, since the regulations subsequently state:

-

End Wall Strength to be indicated on plate only if end walls are designed to withstand a load of less or greater than 0.4 times the maximum permissible payload, i.e. 0.4 P.

-

Side Wall Strength to be indicated on plate only if the side walls are designed to withstand a load of less or greater than 0.6 times the maximum permissible payload, i.e. 0.6 P.

This is based on Paragraph 3 of Regulation 1, which states:

-

Where the Administration considers that a new container satisfies the requirements of the present Convention in respect of safety and if, for such container, the end and/or side-wall strength value (factor) are designed to be greater or less than that stipulated in Annex II such value shall be indicated on the Safety Approval Plate.

|

Positioning of data on the Safety Approval Plate |

"A blank space should also be reserved on the CSC Plate for first and subsequent maintenance examination dates (month and year) when used."

In the example illustrated, this blank space has been left not at the bottom but on the right of the other required data (see arrow). This is common practice.

In the "International Convention for Safe Containers", Regulation 2 of Annex I deals with maintenance, and reads as follows:

| 1. | The owner of the container shall be responsible for maintaining it in safe condition. |

| 2. | The owner of an approved container shall examine the container or have it examined in accordance with the procedure either prescribed or approved by the Contracting Party concerned, at intervals appropriate to operation conditions. The date (month and year) before which a new container shall undergo its first examination shall be marked on the Safety Approval Plate. |

| 3. | The date (month and year) before which the container shall be re-examined shall be clearly marked on the container on or as close as practicable to the Safety Approval Plate and in a manner acceptable to that Contracting Party which prescribed or approved the particular maintenance procedure involved. |

|

Next examination date not stated |

|

Correct: Next examination date entered |

| 4. | The interval from the date of manufacture to the date of the first examination shall not exceed five years. Subsequent examination of new containers and re-examination of existing containers shall be at intervals of not more than thirty months. All examinations shall determine whether the container has any defects which could place any person in danger. |

|

| Correct: Interval between date of manufacture and first examination amounts to 5 years |

The container was manufactured in 1998. On the CSC Plate, the first re-examination date is given as being month 09, i.e. September, 2003 (this is difficult to read on the Figure).

| 5. | For the purposes of this Regulation, "the Contracting Party concerned" is the Contracting Party of the territory in which the owner is domiciled or has his head office. |

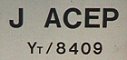

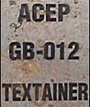

For some years now, owners have in most cases been responsible for examining their own containers. Regulators have provided for this by establishing an "Approved Continuous Examination Program", in which owners participate. ACEP is a recognized repair and maintenance system providing for regular examinations and servicing. To participate actively in this program, it is necessary to register with the competent authorities. Registration is indicated on the container. The owner has then to take responsibility for the necessary inspections and the date for re-examination need no longer be indicated on the CSC plate.

| A valid ACEP renders it unnecessary to indicate a next examination date. |

|

|

|

|

| "Approved Continuous Examination Program" registration data | |||

|

|

|

| Most container owners participate in the ACEP. | ||

Chapter II of the "International Convention for Safe Containers" sets out regulations for approval of new containers by design type, as quoted in detail below:

- Regulation 3 - Approval of new containers

To qualify for approval for safety purposes under the present Convention all new containers shall comply with the requirements set out in Annex II.

- Regulation 4 - Design type approval

In the case of containers for which an application for approval has been submitted, the Administration will examine designs and witness testing of a prototype container to ensure that the containers will conform with the requirements set out in Annex II. When satisfied, the Administration shall notify the applicant in writing that the container meets the requirements of the present Convention and this notification shall entitle the manufacturer to affix the Safety Approval Plate to every container of the design type series.

Regulation 5 sets out the provisions for approval by design type:

| 1. | Where the containers are to be manufactured by design type series, application made to an Administration for approval by design type shall be accompanied by drawings, a design specification of the type of container to be approved, and such other data as may be required by the Administration. |

| 2. | The applicant shall state the identification symbols which will be assigned by the manufacturer to the type of container to which the application for approval relates. |

| 3. | The application shall also be accompanied by an assurance from the manufacturer that he shall: | |

| a) | produce to the Administration such containers of the design type concerned as the Administration may wish to examine; | |

| b) | advise the Administration of any change in the design or specification and await its approval before affixing the Safety Approval Plate to the container; | |

| c) | affix the Safety Approval Plate to each container in the design type series and to no others; | |

| d) | keep a record of containers manufactured to the approved design type. This record shall at least contain the manufacturer's identification numbers, dates of delivery and names and addresses of customers to whom the containers are delivered. | |

| 4. | Approval may be granted by the Administration to containers manufactured as modifications of an approved design type if the Administration is satisfied that the modifications do not affect the validity of tests conducted in the course of design type approval. |

| 5. | The Administration shall not confer on a manufacturer authority to affix Safety Approval Plates on the basis of design type approval unless satisfied that the manufacturer has instituted internal production-control features to ensure that the containers produced will conform to the approved prototype. |

Regulation 6 relates to "Examination during production":

-

In order to ensure that containers of the same design type series are manufactured to the approved design, the Administration shall examine or test as many units as it considers necessary, at any stage during production of the design type series concerned.

Regulation 7 covers "Notification of Administration":

-

The manufacturer shall notify the Administration prior to commencement of production of each new series of containers to be manufactured in accordance with an approved design type.

Chapter III of the CSC sets out "Regulations for approval of new containers by individual approval" and chapter IV sets out "Regulations for approval of existing containers".

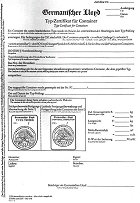

In Germany, Germanischer Lloyd is the "administration" responsible for type testing of containers. Containers are certified if they fulfill the requirements of Annex II with regard to "Structural safety requirements and tests" and of course the other standards to be complied with.

|

|

|

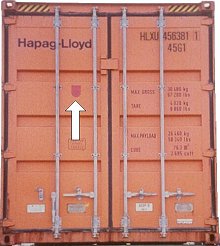

In the case of box containers, the test plate is generally affixed to the left door leaf.

|

|

| Germanischer Lloyd test plates for approval by design type | |

The classification societies mentioned above are just a few examples of the many in existence. Other examples are the Belgian Bureau Veritas, Lloyd's Register in Great Britain, Nippon Kaiji Kyokai in Japan and Det Norske Veritas in Norway.

The Figures show additional plates affixed to the container and/or markings written thereon. In the "International Convention for Safe Containers", Regulation 1, Point 4 comments on this issue as follows:

-

4. The presence of the Safety Approval Plate does not remove the necessity of displaying such labels or other information as may be required by other regulations which may be in force.

|

|

An international customs agreement ensures that empty containers do not count as imported merchandise in member states and are thus free of duty provided that the containers remain only temporarily in the customs territory. In addition, the container itself is deemed to be a bonded space.

|

|

|

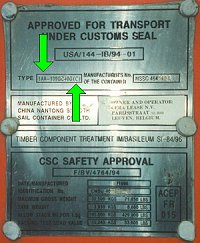

Type test approval, Germanischer Lloyd |

| Although this container was manufactured in China for an owner in Bermuda, it was certified by Germanischer Lloyd. Of interest is the fact that Great Britain is the country of registration of participation in an "Approved Container Examination Program" (ACEP) - a clear demonstration of the globalization of container traffic. |

|

|

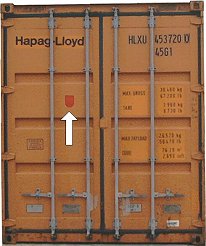

| Container certified by Germanischer Lloyd (GL) with British ACEP | Container certified by Bureau Veritas (BV) with American ACEP |

The various contracting states each recognize one another's national approving bodies. Although the states are bound by the CSC's structural safety requirements and tests, there is nothing to stop them enforcing additional safety requirements for their own containers.

Type testing involves a wide range of test procedures, covering, for example, lifting from top corner castings, lifting from bottom corner castings, lifting using other additional devices on the container such as forklift pockets, grappler arm positions and other methods. The test procedures also extend to stacking and to concentrated loads on roof and floor. Transverse racking is another aspect which is subject to testing. Furthermore, containers must undergo permissible loading capacity tests with regard to longitudinal restraint, the end walls and the side walls.

The introduction to "Structural safety requirements and tests" reads as follows:

| In setting the requirements of this Annex, it is implicit that in all phases of the operation of containers the forces as a result of motion, location, stacking and weight of the loaded container and external forces will not exceed the design strength of the container.

In particular, the following assumptions have been made: |

|

| a) | the container will so be restrained that it is not subjected to forces in excess of those for which it has been designed; |

| b) | the container will have its cargo stowed in accordance with the recommended practices of the trade so that the cargo does not impose upon the container forces in excess of those for which it has been designed. |

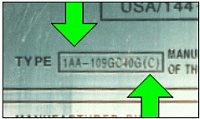

| Testing and certification always relate to a particular type. A valid CSC plate affixed to a particular container tells the user what type of container he has before him. Nonetheless, some CSC plates give further details about this and about other supplementary standards: |  |

|

Selective enlargement on the left

The character combination 1AA indicates a 40' long, 8'6" high standard container, while the letter C here stands for Closed.

|

|

Selective enlargement on the right

This container has also been type tested (yellow arrow). The character combination 1AA indicates a 40' long ISO container 8'6" high. The abbreviation OT stands for open-top (green arrow). The container is not subject to an "Approved Container Examination Program" (ACEP) and the Plate therefore carries the date of its next examination (blue arrow), fully in accordance with regulations. Since the container was built in 1997, its first test falls due in 2002, with subsequent examinations at two and a half year intervals.