|

|

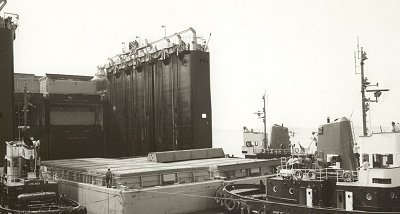

| Hatchless container ship with rain roofs |

Hatchless container ships first appeared around the beginning of the 1990s. They were intended to make cargo handling more economic. In 1993 and 1994, Howaldstwerke-Deutsche Werft AG (HDW) delivered four hatchless container ships to the Swiss shipping company Norasia Line. These vessels were equipped with an innovative cargo protection system. These 2,780 TEU vessels are a further development of the "ship of the future". Except for holds 1 and 2, which are equipped with pontoon hatch covers to allow the carriage of hazardous materials, these vessels have no hatch covers. Since, on their usual route between Europe and Far East, these vessels are exposed to heavy tropical rain, the shipping company decided to equip holds 3 to 7 with twelve rain protection roofs of lightweight steel construction. Each rain roof rests on the transverse coaming of the container cell guides and is secured by rapid fastenings. The coamings extend in each case up to the highest container which, in some holds, amounts to twelve tiers. Before and after cargo handling, the roofs have to be removed and replaced by on-shore lifting gear. Moreover, the roofs constitute part of the aerodynamic hull shape. Windtunnel testing revealed that the shape of the forecastle deck in conjunction with the rain roofs and the deckhouse will save fuel. The rain roofs protect not only the stowed containers, but the ship as well, as large quantities of rain water in the holds cause stability problems. Other owners of "open top" container ships use high power bilge pumps to combat this problem.

|

|

| Reefer container vessel |

Reefer container vessel:Reefer container vessel: almost all container ships have separate connections for refrigerated containers. If these connections are present in relatively large numbers and in a certain ratio to the total TEU capacity, this is reflected in the ship's designation.

|

|

| Container passenger vessel |

Container passenger vessels are a relatively recent phenomenon. In certain countries such as China, Indonesia, Russia and others, they are becoming increasingly important in coastal or island traffic.

|

|

| Feeder ship off the Stromkaje at Bremerhaven |

Feeder ships: These ships carry containers between major container terminals and other ports which are not served by the major shipping lines. Most Indian ports, for example, are served by feeder ships from Colombo, while the ports of western Denmark are served from Bremerhaven. The term "feeder ship" provides no indication as to the size of the vessels, nor as to whether they are equipped with on-board lifting gear. Most feeder ships, however, are relatively small or medium-sized vessels.

The vessels used in feeder service to and from container ports are often customized, as least when put in service. For example, a ship built in 1998 for Caribbean container trade has the following data:

| Length | 90.95 | m |

| Beam | 15.40 | m |

| Molded depth | 7.35 | m |

| Draft | 5.65 | m |

| Deadweight | 4,150 | tdw |

| Container capacity | 312 | TEU |

| Engine power | 3,520 | kW |

| Speed | 15 | kn |

| Loading gear: on-board cranes | 2 | units |

Ore Bulk Container carrier: The multipurpose "OBC" freight carriers developed in the former GDR are highly versatile. The abbreviation stands for Ore, Bulk and Container. Double hull construction means that all the internal surfaces of the hold are smooth. Since these vessels are fitted with high capacity on-board electrohydraulic cranes with a long reach, even poorly equipped ports can be served. In one specific class of vessel, alternate holds (I, III and V) are suitably reinforced for carrying ore. Due to their high strength and large hatches without tween decks, these vessels are well suited to carrying rolling mill products and long goods.

A half-height, double-walled longitudinal girder fitted below deck acts as a grain bulkhead. With the exception of hazardous materials and cement, all possible kinds of bulk cargoes may thus be carried. 576 TEU can be stowed in the holds and on deck. There are also thirty-six reefer connections available.

|

|

| Open bulk container carrier |

Open bulk container carriers also have several unusual features which make such vessels highly versatile, even suiting them for container traffic. These bulk carriers are designed like pure container ships, i.e. a very large proportion of the deck area can be opened and the hatch lengths are arranged in a 40 foot grid. Structures delimiting the hold, such as double bottoms, transverse bulkheads and wing bulkheads are designed to withstand the pressure applied by bulk cargoes. Smooth walls and floors are required to allow straightforward loading and unloading with grabs and wheel loaders, which is why the container foundations are recessed in the double bottom and the ISO holes are covered with plastic or steel lids.

In the vessel shown, containers can be stowed up to seven high in the holds. The stacks are secured at the bottom by twist locks in the tank deck. Container guides providing lateral restraint are folded out from the bulkheads. In each hold, three blocks are formed using single and double stacking cones, with container guides providing guidance and restraint in two planes, so making it possible to withstand the forces arising when the vessel rolls. Such stacking aids are generally provided between the 3rd and 4th and between the 5th and 6th tiers of containers and are sized in line with the maximum admissible container corner loading of 600 kN. A combination of general cargo and/or bulk cargo plus containers may also be stowed in the holds. This is achieved by folding "container brackets" out from the bulkheads onto which a maximum of four tiers of containers, each applying a load of 300 kN, may be loaded over the bulk cargo or general cargo.

As has already been mentioned, ro/ro stands for roll-on/roll-off, i.e. it is a description of how the cargo is handled. The type of cargo being carried is not automatically known as it may comprise any kind of rolling cargo or cargo which has been made rollable. In many cases ro/ro ships also carry other cargoes without this being clear from the vessel's designation.

There is, however, one feature common to all ro/ro ships - they can be loaded via bow, stern or side ports. If the ships have several decks, access is provided by elevators or ramps.

Ferries are equipped to carry both passengers and rolling cargo, which may comprise automobiles, trucks, chassis, trailers or railroad vehicles. In many cases, cargo is carried on "cassettes" which are packed and unpacked in port and transferred on and off the vessel with special tractors. Containers are only loaded or unloaded indirectly using roll trailers or the like. Stern, bow and/or side ports ensure rapid cargo handling. In many types of vessel, a one-way system is used, ensuring "first in first out" traffic flow.

In ferry transport, a distinction is drawn between accompanied vehicles, where the driver drives on board, travels with the vehicle and drives off again, and unaccompanied vehicles. Only auxiliary loading gear is usually present.

|

|

| Ferry with bow and stern doors |

Many passenger/railroad ferries and ferries capable of carrying both railroad vehicles and trailers, chassis or other road vehicles are in service in short-sea ro/ro traffic in the North Sea, Baltic and also Mediterranean.

These vessels have bow thrusters to ensure rapid berthing and casting off. Maneuvering is often facilitated by pitch propellers or a multiscrew design of the vessel. Ferries are often symmetrical in structure and may be operated and accessed from either end. Special cargo securing systems are provided, but are often used only in poor weather. Most cargo damage and sinkings are caused by inadequate stowage and securing on the vehicles, as has been shown by many incidents of loss and accidents in recent years.

|

|

| Container-ro/ro ship |

Container-ro/ro ships (conro) carry both containers and rolling cargo. Ro/ro cargoes are mainly loaded below deck, while containers are primarily stowed on deck. In some vessels, e.g. ACL or Polish Ocean Line, special container shafts are provided in the forward third of the ship to accommodate containers below deck. In regions of service with high cargo volumes, container handling is carried out by on-shore gantry cranes. The ships rarely have their own loading gear. The "Finnsailor" is one such ship which carries rolling or rollable cargo below deck and containers, plant, general cargo etc. on deck. However, these facts were not taken into account by the shipyard when determining the ship's designation.

Ro/ro-lo/lo carriers are ships which are capable of loading and stowing cargoes both via ramps using roll-on/roll-off methods and with on-board lifting gear using the lift-on/lift-off method. Such vessels accordingly also have upper deck hatches and, in some cases, holds divided by transverse bulkheads.

|

|

| Ro/ro-lo/lo Carrier |

|

|

| Ro/ro-lo/lo-container ship |

This double hull ship is an example of a ro/ro-lo/lo-container vessel. It has a ro/ro component in the form of a stern door. On the port side it has an internal vehicle ramp to provide access to the two 'tween decks. The fitted on-board cranes allow containers to be handled in ports without on-shore lifting gear.

Barge carriers are specialized container transport vessels. Barge carriers are very largely capable of operating independently of ports, they depend on relatively calm areas of water or "floating areas" for transferring the barges. This fact explains the great strategic significance of the system because barges can be set down and picked up at virtually any coast. Barge transport operations are only worthwhile between economic areas which have virtually identical volumes of goods passing in each direction, and in particular where inland waterways lead inland so that good use can be made of the advantages of the floating containers. The high cost of building the ships and the capital expenditure for three sets of barges mean that such systems are not economically viable everywhere. There are various different systems:

|

|

| LASH carrier |

LASH stands for Lighters Aboard SHip. In the LASH system, barges are carried athwartships in holds and on deck. The barges are picked up and set down at the stern by the LASH's on-board gantry crane using spreaders. Distinguishing external features of these carriers are the far forward location of the superstructures or deck houses, the location of the exhaust stacks to the aft and sides, the stern outriggers and the large gantry crane with a lifting capacity of more than 500 metric tons. This type of vessel hit the headlines some years ago with the sinking of the "München". Twenty-six vessels of this class are still in operation worldwide. Deadweight is approx. 43,000 metric tons, i.e. approx. 73 - 83 barges can be carried in addition to equipment, bunker fuel and stores.

|

Embarking LASH barges in the floating area |

The dimensions of the barges are 18.50 m x 9.50 m x 3.90 m. Fully laden, the draft is 2.61 m. With a tare weight of approx. 140 metric tons, the deadweight of the barges is 376 metric tons. The difference in draft between bow and stern or "trim" must not exceed one foot as the barges otherwise can no longer be lifted by the spreader.

| Stern embarkation of LASH barges by gantry crane |  |

Special framework platforms have been developed so that not all goods need to be carried in the barges with their high tare weight. Floored platforms of this kind are available for general cargo, automobiles etc., while there are also floorless versions for containers. For cargo handling purposes, these platforms are set down on "feeder" barges which are towed to and from the ship. The framework platforms are also handled by the gantry crane.

|

|

| SEABEE carrier in a floating area |

SEABEE carriers are capable of embarking barges at the stern using winch-driven lift platforms with a load-carrying capacity of more than 2,000 metric tons. Barges are loaded, usually in pairs, by being floated into the dock-like afterbody of the ship over the lowered lifting platforms, then lifted up to deck height, from where they are rolled into the ship on very flat rail-mounted trolleys. This type of transfer is thus known as "lift and roll". The Lykes Line's SEABEE ships can stow thirty-eight barges on three decks. Special fittings allow the upper deck to be loaded with containers instead of barges. SEABEE ships are able to carry containers and other cargoes on deck, but these ships do not have on-board lifting gear for such cargoes.

|

|

| Floating a barge over the lowered winch platform |

SEABEE barges measure 29.72 m x 10.67 m x 5.18 m. With a tare weight of 171.5 metric tons, the unladen draft is 0.62 m. With a full payload of 844 metric tons, the maximum draft is 3.22 m. There may be slight differences depending upon the particular type and lighter. The barges can accommodate six FEU or twelve TEU. Sixteen FEU can be located on the barge's hatch covers.

|

|

| Side view and plan view of a BACO liner |

BACO liners (barge/container liners) operate in accordance with the dock principle. In this German-developed system, the barges are floated through bow doors into the carrier, which has been lowered by taking on ballast. Once the bow doors have been closed, the water is pumped out of the dock and the barges are secured with special fittings. The special BACO barges measure 24 m x 9.50 m and, at a deadweight of 800 metric tons, have a draft of 4.10 m. However, the particular dimensions of the carrier ships are such that other types of barge and even inland waterway vessels and lighters can also be carried. Several tiers of containers can be carried on deck and be loaded and unloaded with on-board lifting gear.

CONDOCK is derived from container and dock ship. A large hold can be loaded with rolling cargo via a stern ramp as well as from above using the lo/lo method. These vessels have their own, very high capacity lifting gear for carrying heavy-lift cargoes. Containers can be carried in three tiers on deck. By flooding their ballast tanks, they can be lowered in the water like floating docks, and can take on floating cargoes. The dimensions of those vessels which are in service are such that LASH, BACO and sometimes even SEABEE barges can be accommodated. This class of vessel is still more versatile. Its gantry cranes are capable of handling individual items of cargo of up to 1,000 metric tons by the lo/lo method. Using the ro/ro method, heavy items of up to 2,000 metric tons can be loaded into the hold via a 20 m x 10 m ramp, while heavy and bulky items can be rolled on deck via two stern outriggers and self-propelled bogies. Floating cargo can be stowed either in the hold using the flo/flo method or on deck using the piggyback system.

The following examples are intended to illustrate how good design can enormously increase the versatility of modern ships.

|

|

| Coastal motor vessel capable of navigating the Rhine and canals |

Coastal motor vessels capable of navigating the Rhine and canals have a continuous box shaped cargo hold and a deadweight of 1,550 metric tons. The essential difference between other classes of sea/river-going vessels resides in this vessel's crane, which is of collapsible construction and so does not exceed the maximum height for navigating the Rhine and canals. The vessel's hatch covers can accommodate 20' or 40' containers in several bays. The wheel house can be lowered and raised hydraulically, while the masts can be folded down.

The majority of the inland waterway motor vessels in service in Germany are used to carry dry cargoes. Lengths vary between 38.50 m and 110 m, beams between 5 m and 11 m and drafts between 2 m and 3.50 laden. The deadweight of such vessels is between 220 metric tons and 3,000 metric tons. Many of these vessels are equipped to carry containers. Some single hold motor freighters have been specially tailored to the conditions prevailing on the Rhine on the way to Basel. They have the largest possible hold volume for light bulk cargoes, but can also carry heavy-lifts and bulky cargoes. Heavy goods can be rolled from land via an external ramp onto the forebody, from where they can be rolled into the hold via an internal ramp with a gradient of 5°. Low loaders, trailers or other special purpose trucks and crawlers can be used for this purpose. Loading and unloading operations can be assisted by hydraulic equipment, trim tanks and a pump system.