The following requirements are placed on packaging containers for fresh fruit and vegetables, in accordance with metabolic processes and transport stresses:

- optimum permeation of the packaging units with cooling air for chilling the product

- water vapor permeability of packaging in accordance with the product's requirements, in order to prevent mold and rot due to excessive moisture, while also preventing wilting, shrinkage and weight loss due to drying-out

- optimum gas permeability (optionally by perforation), which must firstly supply oxygen in fresh air and secondly remove harmful substances such as carbon dioxide and ethylene

- strength, in order to avoid bruising. To fulfill these requirements, cartons for fresh fruit and vegetables have perforations which ensure that air flows through the packages or circulates around the product.

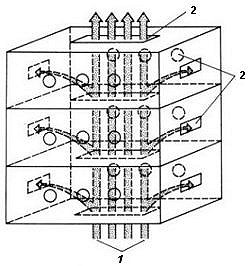

Fig. 102 illustrates vertical air flow through perforated cartons, a vital point being that the perforations in the stacked cartons must correspond exactly so that the air can flow vertically through all the cartons. This is why the perforations are arranged directly opposite each other.

|

Figure 102: Vertical air flow through perforated cartons 1 - vertically flowing cooling air 2 - perforations in cartons |

Table 9 shows the perforation content for the transport of a number of tropical and subtropical fruits.

| Cargo type | Exporting country |

Packaging container |

Packaging material |

Tare in g |

Total tare in g |

Perforation content in % |

| Grapefruit | Cuba | Folding telescope carton |

D WP 1 B WP 2 |

D 350 B 550 |

900 | 1.68 |

| Tangerines/ mandarins |

Cuba | Folding telescope carton |

D WP 1 B WP 1 |

D 340 B 400 |

740 | 1.65 |

| Mandarins | Uruguay | Folding telescope carton |

D WP 1 B WP 1 |

D 400 B 640 |

1,040 | 2.15 |

| Oranges | Uruguay | Folding telescope carton |

D WP 1 B WP 2 |

D 500 B 780 |

1,280 | 2.13 |

| Bananas | Ecuador | Folding telescope carton |

D WP 1 B WP 2 |

D 450 B 600 |

1,050 | 8.18 |

Table 9: Perforation content of shipping cartons for the transport of tropical and subtropical fruits

| L - Lid part | CB 1 - Corrugated board, single wall |

| B - Base part | CB 2 - Corrugated board, double wall |

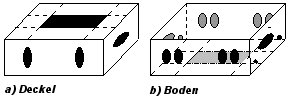

The cartons for bananas from Ecuador are optimally perforated for vertical air flow. The lid and base parts of folding telescope cartons for bananas are each respectively provided with an opening of 280 cm² or 220 cm², so allowing unhindered vertical air flow. The end faces are provided with 5x8 cm holes, which also serve as handles (see Fig. 103).

|

| Figure 103: Folding telescope cartons for bananas, Cavendish variety, from Ecuador |

The proportion of the total surface area of a closed folding telescope carton occupied by perforations amounts to 8.18%. In addition, the bananas, which are additionally packaged in perforated polyethylene bags in the cartons, may be easily checked for ripeness and any condensation water formation.

Fig. 104 shows an example of packaging for Cape grapes. Fruit is often also wrapped in an inner packaging of paper, e.g. pears from Brazil in sulfate paper (as protection from light). Chicory is protected from light and drying out with dark blue paraffin paper. Oranges are wrapped up in tissue paper, which is often treated with fungicidal/bactericidal substances. The fruit is cushioned against pressure and impact and is often packed in shaped trays (e.g. of rigid PVC film), which separate the layers of fruit.

Kiwifruit are packed in a single layer in attractive wooden, plastic or cardboard trays fitted with plastic inserts, to ensure impact resistance. Peaches are also transported in flat fruit crates with plastic inserts. Heads of broccoli and lettuce are individually protected with film and packaged in fruit crates.

Frozen fruit and vegetables are transported in shipping packages in the form of folding cartons of corrugated board, which are usually treated with paraffin to prevent evaporation losses.

|

Figure 104: Cape grapes in corrugated board carton |

To ensure a vertical flow of cooling air, lid and base have each been provided with a large opening; in addition four round holes have been provided, along with four holes in the edge area.

The grapes are protected by a perforated polyethylene bag. Butter and fats are packaged in millboard cartons provided with an internal lining designed to make the cartons largely impermeable to air and oxygen, so as to be able to prevent oxidative reactions, which lead to rancidity. Meat and fish are shipped in cartons of millboard or corrugated board and in wooden cases.