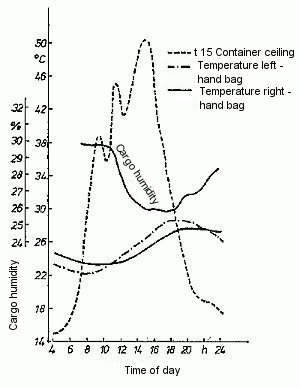

Investigations by the hold meteorology study group reveal among other things that, starting with a dry container ceiling and side walls, sweat coverage increases in stages and reaches a maximum after a few days. The interaction of all the various factors leads to the following presumed mechanism for the formation of sweat in the container: during heating of the container surfaces and thus also of the internal air and the cargo surface, the relative humidity of the container air falls. The container floors and the cargo release water vapor into the ambient air in accordance with their temperature and with desorption characteristics. The absolute humidity of the internal air increases. Through further heating of the container air, the relative humidity falls further. In the event of heating to a maximum temperature of 50°C, the residual air quantity in the container could absorb approximately 1,800 g of water vapor. However, the actual quantity is lower, since water vapor saturation of the air is not reached during the heating process. The water vapor emitted into the air is supplied by the surface layers of the cargo, i.e. the vapor pressure also drops inside the stack and thus moisture flows from the interior to the outside of the cargo. Such moisture is easily detected. Thus, given an average sweat coverage of the container surface, the water content of the cargo ought to have fallen by approximately 0.64%. However, the water content of the surface batches was actually observed to drop by several percent. This process is illustrated in Fig. 18.

|

Figure 18: Temperature and water content of the product surface and ceiling temperature of the container on a sunny day; Svenson [54] |

If the container heating maximum is exceeded, the temperature of the container air falls and the relative humidity rises. An essential factor is that the cargo absorbs water vapor very much more slowly ("adsorption retardation"), as a result of the moisture flow in the cargo itself and the later arrival at the cargo temperature maximum.

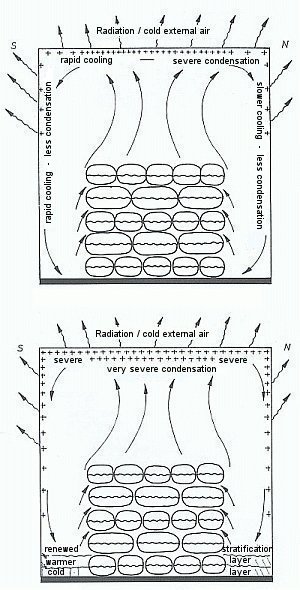

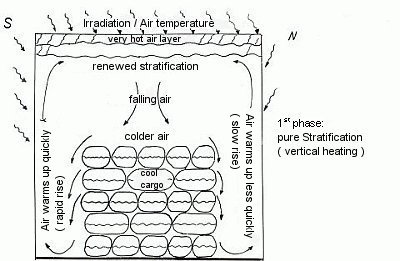

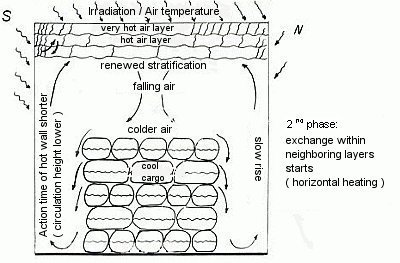

Part of the water vapor condenses on the cooling container walls as soon as their temperature falls below the dew point temperature of the internal air. Sweat starts to form on the ceiling and the vertical walls. When heating next occurs, part of the water vapor absorbed by the internal air is supplied by the sweat on the vertical walls. To bring about a vapor pressure equilibrium between cargo and air, the cargo needs to emit less water vapor. Due to the stable air stratification which occurs, the sweat on the ceiling does not come into thermal contact with circulating air and can only develop by diffusion into lower, drier masses of air (see Figs. 19, 21 and 22). This process proceeds more slowly than the absorption of evaporation sweat by the drier air flowing past the vertical container surfaces. Under the container ceiling, the sweat does not dry off despite considerable overheating of the roof. This water is replaced by further desorption from the cargo. Thus, the quantity of sweat on the container surfaces increases in stages from day to day, until a maximum is reached. This can only be dealt with by destroying the stable air strata in the container by active ventilation, for which the ventilation openings present are inadequate, however.

|

1st phase: pure stratification (vertical cooling) |

| 2nd phase: exchange within neighboring layers starts (horizontal cooling) |

|

| Figure 19: Sweat formation under the ceiling of the container in radiation weather; U. Scharnow |

|

Fig. 19 shows clearly that the majority of the sweat is on the container ceiling. This fact is of particular significance because sweat on the wall can run off without causing major damage, while sweat on the roof drips directly onto the stored cargo and so constitutes the greater risk.

Another conclusion which may be drawn is that more sweat is formed as radiation conditions improve. Goods packed in a container are exposed to a much lower level of risk under conditions with little radiation than under good radiation conditions.

In the case of a closed standard container, the following loss prevention measures are recommended for safe transport:

- keep the water content of the cargo, packaging and container floor low, since this makes for less intense sweat formation

- protect the cargo from dripping water

- choose the stowage space in such a way that the containers are not exposed to any radiation

- leave ventilation openings open or choose ventilated containers, so that warm air with a high water vapor content is dissipated

|

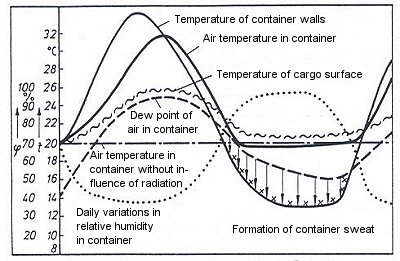

| Figure 20: Schematic representation of the daily variations in the air, dew point and interface temperatures and the container sweat they bring about; U. Scharnow [43] |

Figure 20 is a schematic representation of the daily variations in the air, dew point and interface temperatures which determine the storage climate and the formation of container sweat such variations cause, leading to the following conclusions:

The most persistent sweat formation in the container takes place during radiation weather, if the container is exposed to direct solar radiation during the day and is subject to outward radiation at night. Intensive heating of the air leads to a reduction in the relative humidity in the container, encouraging water vapor release from the cargo. The dew point of the air in the container rises. After sunset cooling occurs. If the temperature of the container falls below the dew point of the air in the container, condensation arises on the container ceiling and walls. Next day, the water condensed on the walls dries up again, but not the water under the container ceiling, which remains there as a result of stable stratification and increases day by day until it starts to drip (see Figs. 21 and 22).

|

|

| Figure 21 (top) and 22: Formation of container sweat in radiation weather; Svenson [54] |